Complete Equipment and Machinery for Cottonseed Oil Mill Plant

- Type: cottonseed oil equipment

- Usage/Application: cottonseed

- Dimension (L*W*H): 1700*1300*1600

- Weight: 800 KG

- Machinery capacity: cocoa butter making machine

- Power: 18Kw

- Voltage: 220V/380V, can be customized

- Country: johannesburg

Cottonseed oil is extracted from the seeds of cotton plants. Refined cotton seed oil is edible. India, China, Pakistan, USA and Brazil are among the top producers of cotton seed oil in the world. Let us now know about the various aspects of cottonseed oil plant - it's manufacturing process, world market status and other features.

cotton seed oil mill project report

- Type: cottonseed oil refinery machine

- Production capacity: 15-20 kg/h

- Voltage: 220 V

- Main components: Others

- Weight: 73 KG

- Dimension (L*W*H): 640*290*680 mm

The top concern about setting up cotton seed oil mill plant is the project cost. But, the investment and working capital for a complete cottonseed oil manufacturing plant is decided by many factors, such as capacity, equipment type, oil processing methods, raw material price, local and international market demand, etc..

The production of our refined cottonseed oil begins with the harvesting of the cotton plant. After the fibers have been separated for use in the textile industry, the seeds remain. These seeds are cleaned and freed from foreign matter and cotton lint. Next, the seeds are ginned and hulled, whereby the hulls are removed and used as a by-product.

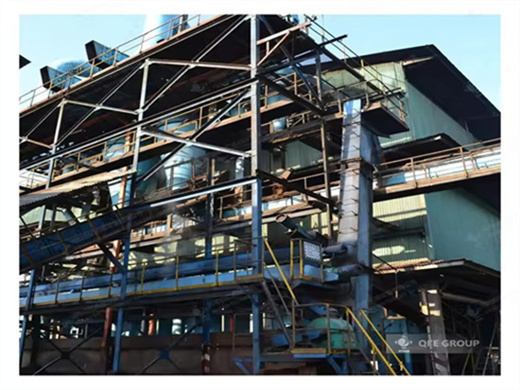

Oils Fats Refining Equipment and Turnkey Plants - Myande Group

- Usage: cottonseed oil

- Production capacity: 10T-3000T/D

- Voltage: Local voltage

- Weight: Cooking Oil Extraction Machine According to Your Request

- Dimension (L*W*H): Cooking Oil Extraction According to Your Request

- Power (W): Capacity

We can provide edible oil refining plant equipment with capacity ranging from 50 t/d to 4,000 t/d for soybean oil, rapeseed oil, sunflower seed oil, cottonseed oil, rice bran oil, palm oil, corn oil, peanut oil, linseed oil, animal fats and oils, chicken fat, butter, fish oil and etc. Refining is the last step in edible oil processing.

This small small oil mill is not only suitable for cotton seeds, it is also ideal choice for extracting oil from many other oil seeds and nuts, such as mustard seed, peanut, flaxseed, linseed, poppyseed, groundnuts, sesame seed, canola seed, sunflower seed, soybeans, etc. The equipment for running a small scale oil-pressing mill may include

Cottonseed Oil Manufacturing Process and Machinery

- Type: cooking oil refining machine

- Production capacity: depending on model

- Dimension (L*W*H): 400x500x850

- Voltage: 220v

- Weight: 250 KG

- Main components: motor, others

It’s very simple in nature and can be used to extract oil from various seed plants. The screw cottonseed oil press is a mini cottonseed oil machine that can be used for small-scale extraction oil plants. Some of the seed plants that be extracted by it are soybeans, peanut, sunflower, copra, rapeseed, palm kernel, mustard seed, and more.

In fact, most small crude oil refineries are faced with the shortcomings of crude oil refining equipment, backwardprocess, low quality of refined oil. To this end, Bandung Machinery has launched the most cost-effective crude oil refinery to meet the needs of small crude oil refineries with a normal capacity of 1 to 10 tons per day.

Cotton Seed Oil Manufacturing Project Report - Idea2MakeMoney

- Raw Material: cottonseed oil

- Raw material: Seeds

- Available quantity: 10000PCS

- Supply type: OEM/ODM

- Ingredient: Flaxseed

- Feature: Skin Revitalizer, Moisturizer, Pore Cleanser

Market potential of Cotton Seed Oil. There is a huge demand for oil in the market. Almost all households and restaurants will consume oil daily in food items such as curries and biryanis etc, the market is rising at 10-15% every year.

Thanks to our extensive experience with refined cotton manufacturers in the chemical fiber industry, it can be seen from the experimental data in the past five years that this set of refined cotton production equipment can reduce COD emissions, enabling the cotton lint processing enterprises to reduce chemical emissions and develop in the direction of environmental protection and energy saving.