palm oil refinery machine in south africa - Vegetable Seed Oil

- Type: palm oil machine

- Usage/Application: palm fruit, palm kernel

- Production capacity:5TPD

- Voltage: 380V/415V three phase

- Weight: 30 tons

- Dimension (length x width x height): 2000*1500*1000

- Power: 55-450

- Country: south africa

We have a professional overseas engineering team that can independently complete palm oil equipment installation and commissioning, or collaborate with local construction parties to efficiently implement it – whether it is a 15tph palm oil processing plant in the Democratic Republic of the kenya or the 10tph palm fruit oil pressing line in Thailand, we have achieved complete delivery.

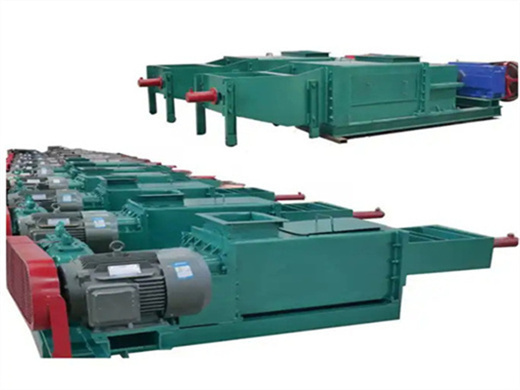

Palm Oil Machine - Palm Oil Production Line

- Type: palm oil refinery machine

- Voltage: 380V

- Dimension (L*W*H): 2400mmx900mmx2000mm

- Material: steel cardboard

- Color: stainless steel color or customizable color

- Main components: Motor

Henan Hongde Cereals and Oils Machinery Co., Ltd. has been focusing on the research and development and manufacturing of palm oil processing machine for more than 37 years, providing a full set of solutions from palm fruit pressing to palm oil refining. Palm oil machinery cover different scales of processing from 10 to 1,000 tons per day(TPD

palm oil turn-key project epc Hongde has rich experience in general contracting of EPC project. With excellent product quality, worry-free project services and comprehensive project management, many domestic and foreign companies have selected Hongde, and all have been successfully finished.

Palm Oil Refining Processing Machinery - Find Edible Oil

- Usage: palm oil

- Fully automatic

- Production capacity: according to your needs, 10-3000TD

- Dimension (L*W*H): According to your needs

- Power (W): according to your needs, All the power of the machine

- Voltage: according to your needs

Physical palm oil refinery plant is featured of high efficiency, simple production process and low effluent load. Chemical Refining of Palm Oil; In the chemical refining process, the FFA is removed by neutralisation with caustic soda (sodium hydroxide). This chemical reaction produces neutralised CPO and a soap stock.

Before extracting oil, the palm fruits need to be crushed in digester machines. To augment oil yield, the fruit pulp is also warmed in this process. The mesocarp and nuts can be squeezed together in palm oil making/pressing machine. But if you plan to make Grade A Palm Oil, the palm nut/kernel should be removed before oil pressing section.

Palm oil production line | Palm oil mill - Hongde Oil Machinery

- Type: cooking oil refining machine

- Production capacity: 400~600 kg/h

- Power (W): 18.5 kW

- Voltage: 220V/380V

- Dimension (L*W*H): 1500*1600*2500mm

- Weight: 2000kg

The main steps of crude palm oil refining. CPO(crude palm oil)→ refining → bleaching → deodorizing →RBD palm oil → crystallization → fractionation → RBD olein & RBD stearin. Palm Oil Refinery equipment is the important palm oil machinery and equipment to ensure the quality, grade and safety of palm oil in the processing

The six processes of palm oil refining machine. palm oil refining equipment to remove harmful substances at the same time, but also better preservation of oil in the Vitamin A and Vitamin E and other nutrients, to improve the quality of palm oil. 2024-08-07

Ce Approved Palm Oil Refining Machine Belgium in malawi

- Raw Material: palm

- Production capacity: 1-50t/d

- Power ( W): 15-50KW

- Voltage: 380V/415v

- Dimension (L*W*H): 1200*400*900mm3

- Weight: 1000kg

Palm oil processing and production process. Palm oil processing. Alfa Laval has worked alongside palm oil producers since the earliest days of the industry. More than 50 years’ experience has gone into smart palm oil processing solutions for the entire supply chain – milling, POME management, refining and more.

south africa rapeseed oil refinery palm oil refining machine. palm edible oil refining machine sesame oil refinery machine. digestion is the process of releasing the palm oil refining machine in the fruit through the rupture or breaking down of the oil-bearing cells. the digester commonly used consists of a steam-heated cylindrical vessel fitted with a central rotating shaft carrying a number of