Peanut Oil Processing Plant Manufacturer - Oil Mill Plant

- Type: peanut oil processing plant

- Usage/Application: peanut, groundnut

- Production capacity: 5-1000 TPD

- Voltage: 220v/380v/440v or local voltage

- Weight: Depends on the capacity of the cooking oil extraction machine

- Dimension (L*W*H): Depends on the capacity of the cooking oil extraction machine

- Power (W): Depends on the capacity of the daily cooking oil extraction machine

- Country: afghanistan

So for edible oil, the pressed peanut oil needs to be extracted in the oil extraction plant before the extracted oils are sent to the oil refining plant for further processing. Big Scale Peanut Oil Plant and Small Scale Peanut Oil Processing Plant. Below are the raw materials for peanut oil, as well as the workshop of KMEC’s peanut oil plant

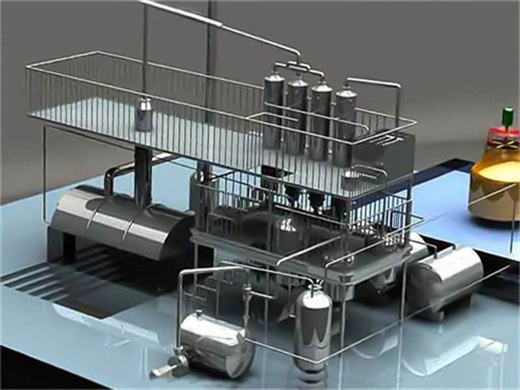

Groundnut Oil Refining Plant | Peanut Oil Processing Plant

- Type: peanut oil processing machine

- Production capacity: 500-1000kg/24H

- Voltage: 220/380v, 220/380 v

- Main components: motor, motor

- Weight: 240KG, 240kg

- Dimension (L*W*H): 1850* 1050*1750mm

Deodorization of Groundnut oil is a vacuum stripping process in which a given amount of a stripping steam is passed for a given period of time through hot oil at a low pressure which removes various volatile components and fatty acids to increase the self-life, and maintained the good odour free test of product.

Above is the main peanut oil extraction methods that are widely used in commercial vegetable oil processing plant to improve the oil production efficiency and oil quality. Before starting the peanut oil extraction process, the peanut/groundnut should be pretreated to ensure high oil output.

Peanut Oil Manufacturing Plant Report: Setup & Cost - IMARC Group

- Usage: peanut oil

- Production capacity: 150-300 kg/h

- Voltage: 220v/380v/Customer request

- Main components: Motor

- Weight: 1100 KG

- Dimension (L*W*H): 1900* 1400*1700mm

IMARC Group’s report, titled “Peanut Oil Manufacturing Plant Project Report 2025: Industry Trends, Plant Setup, Machinery, Raw Materials, Investment Opportunities, Cost and Revenue” provides a complete roadmap for setting up a peanut oil manufacturing plant. It covers a comprehensive market overview to micro-level information such as unit

The general capacity we can provide for peanut oil processing plant ranges from 5 to 400 tons per day. Taking the smallest peanut oil production line (5TPD) as example, the totally investment for a complete automatic peanut oil production line is $ 8,500 around (Not include the oil refining equipment). Please note all the equipment included in

Fully Automatic Groundnut/Peanut Oil Production Line

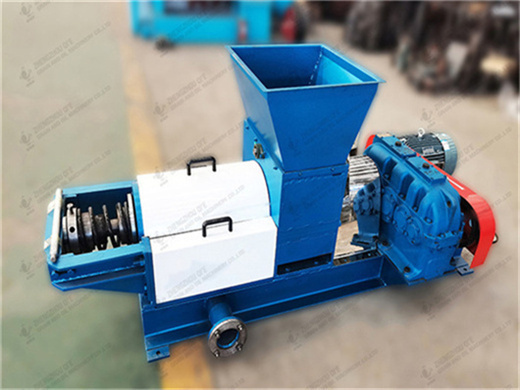

- Type: cooking oil extraction machine

- Production capacity: according to capacity

- Power(W): according to capacity

- Voltage: 110V,220V,380V,440V

- Dimension(L*W*H): 1610x615x1260mm

- Weight: 1050 KG

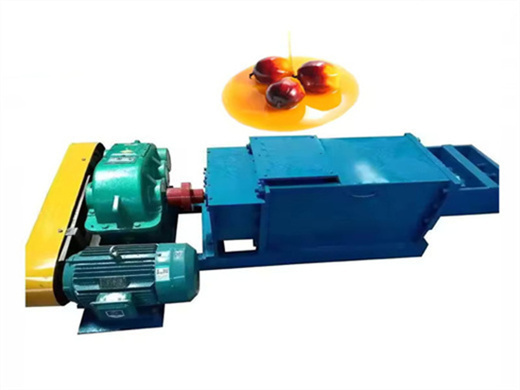

Peanut Oil Production Line. Peanut is a kind of oilseed with high oil content. The oil can be obtained from peanuts by pressing process. Groundnut oil contains more than 80% unsaturated fatty acids (including 41.2% oleic acid and 37.6% linoleic acid).

But it still contains several oil-soluble and in oil-soluble impurities. Therefore, it is essential to equip the peanut oil production plant with professional edible oil refinery equipment to get them off and obtain the refined high-quality peanut oil. Groundnut Oil Processing Flowchart. Cost of Groundnut oil extraction machine:

Peanut Oil Production Line,Peanut Oil Pressing Plant

- Raw Material: peanut

- Production capacity: 100-1000 kg/h

- Dimension (L*W*H): 9600X1800X1850mm

- Voltage: 380 V

- Weight: 5320 KG

- Main components: Others, gears

The disadvantage is low oil yield, not suitable for small oil plant. Peanut Oil Introduction. Peanut oil (groundnut oil), as a kind of light yellow transparent edible oil with a pleasant fragrance and good taste, is relatively easy to digest. Peanut oil contains more than 80% unsaturated fatty acids (including 41.2% oleic acid and 37.6%

Step 4: Pressing. The peanuts are transfer by conveyor and fed through the hopper of screw press machine. Continuous transport of material by the screw shaft causes pressure to increase to a level needed, which increases friction inside the screw press and generates heat which lowers viscosity of the oil in the crushed seeds thereby increasing the oil flow rate.