Master Coconut Oil Processing: From Pretreatment to Refining

- Type: coconut oil processing plant

- Usage/Application: coconut, copra

- Production capacity: 10T-5000TPD

- Voltage: 220V/380V/440V

- Weight: 2T-20T

- Dimension (L*W*H): 2500mm*2000mm*3000mm

- Power (W ): 10kw-50kw

- Country: uganda

Coconut oil processing plant. Explore the world of coconut oil production with Huatai's advanced facilities, designed for high efficiency and maximum yield. Our video highlights our capacity to process vast quantities of coconut oil, from 30 to 1000 TPD, and our sophisticated solvent extraction techniques that ensure every drop of oil is captured.

Copra/Coconut Oil Milling Process - Offered by Oil Mill Plant

- Type: coconut oil processing machine

- Press Materials: Sunflower, All Seeds

- Press Series: Quarter

- Machine Type: 6yl-130 cooking oil processing machine

- Suit for: Sunflower, soybean, peanut

- Custom: Customized

Copra normally has an oil content varying from 65 to 72 per cent. The quality of an ISO certified coconut oil is related to the quality of copra we use. The most commonly coconut oil is refined, bleached and deodorised coconut oil or RBD coconut oil, which is produced from dry coconut meat (copra). RBD coconut oil is produced from copra.

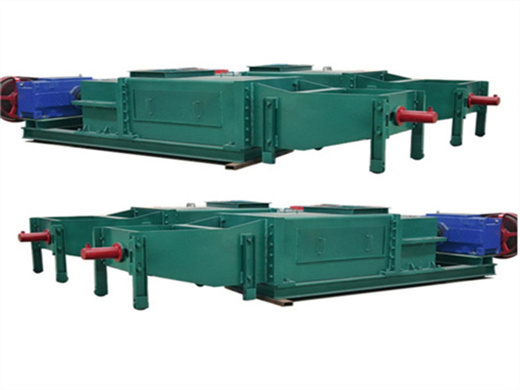

Coconut oil plant adopts twice pressing technology to produce coconut oil from the dried copra. The coconut oil production line mainly includes copra pretreatment and oil pressing process, oil refining process. Copra cake produced after pressing can be used as animal feed. We provide 30-1000 TPD coconut oil processing machine and 1-600 TPD

Coconut Oil Manufacturing Process Flowchart - Oil Expeller

- Usage: coconut oil

- Automatic grade: Automatic

- Production capacity: depends on your requirements

- Weight: 25000 KG

- Dimension (L* W* H): as model

- Voltage: According to your standard

Here are some business opportunities in coconut oil production business at many places around the world including India, Indonesia, Philippines, south africaia and Africa. Equipment & Machinery for starting Coconut oil Manufacturing business: Here are the important coconut oil manufacturing plant machines you need to start an oil manufacturing business:

The journey of coconut oil production progresses with the heating of either the freshly extracted coconut milk or the dried coconut meat known as copra. In the wet mill method, the coconut milk is gently heated, allowing the lighter oil molecules to separate and rise to the top, a process that can be enhanced by fermentation or other separation

[Plant Design] Invest Coconut Oil Refining Business

- Type: cooking oil extraction machine

- Production capacity: 100%

- Voltage: 220V/380V/440V

- Weight : 30 tons

- Dimension (L*W) *H): 48m*12M*15M(30TPD)

- Power (W): 18.5 KW/T

The layout design requirements to maximize a coconut oil plant include: 1. Satisfy Coconut Oil Production Process Requirements; The design of a coconut oil plant should fully consider the characteristics of coconut oil refining, including coconut oil production process and technology, packaging and transportation of raw materials and final

IMARC Group’s report, titled “Coconut Processing Plant Project Report 2025: Industry Trends, Plant Setup, Machinery, Raw Materials, Investment Opportunities, Cost and Revenue” provides a complete roadmap for setting up a coconut processing plant. It covers a comprehensive market overview to micro-level information such as unit operations

Coconut Oil Processing Line Manufacturers, Suppliers, Factory

- Raw Material: coconut

- Production capacity: 10TPD

- Dimension (L*W*H): 1.2*0.78*1.1m

- Voltage: 220V380V

- Weight: 300 KG

- Main components: Motor, pressure vessel, PLC

We warmly welcome you to buy cheap coconut oil processing line from our factory. service@zzmiracle.com +86-371-60922138. Follow Us. Language. English; Deutsch; Italiano;

Coconut Oil Manufacturing Plant Project Report 2025 Edition. Report Coverage: Industry Analysis (Market Performance, Segments, Price Analysis, Outlook), Detailed Process Flow (Product Overview, Unit Operations, Raw Materials, Quality Assurance), Requirements and Cost (Machinery, Raw Materials, Packaging, Transportation, Utility, Human Resource), Project Economics (Capital Investments