Palm Oil Processing Machine for Sale

- Type: palm oil equipment

- Usage/Application: palm fruit, palm kernel

- Production capacity: 250L/H

- Voltage: 220V

- Main components: motor, pump

- Weight: 750 kg, 600 KG

- Dimension (L*W*H): 1500*1680*2980mm

- Country: pakistan

A mill with multiple palm oil extraction machines can deliver up to 120 tonnes per hour. The palm oil digester machine is used to crush palm pulp and crack the inner pulp to make oil pressing and extraction easier. The palm oil screw press machine extracts oil from the palm fruit. After pressing the palm fruits, it discharges the palm oil

Professional Palm Oil Digester Machine, Palm Fruit Digester

- Type: palm oil processing machine

- Production capacity: 100% oil press machine

- Voltage: 220V/380V/440V

- Weight: 950KG

- Dimension (L*W* H): 1950*1300*1900, according to capacity

- Power (W): 5.5 ~ 18.5 KW

Kindly give me a quotation for a 2TPH mini palm oil mill with the following equipment: Thresher, cooker, auger conveyor, digester, presser, clarifier and hydraulic machine that can cut big ffb to small sizes. Hello, Sir/Madam, We have successfully set up a 2TPH Palm Oil Mill Plant in south africaia. You can have reference.

Industrial applications of palm oil equipment. Palm oil equipment has wide usage in many industries. Here are the equipment's applications. Food industry. The food industry uses palm oil in many foods like baked goods, snacks, and fried foods. People like it because it makes food crispy without changing the food's taste.

Buy Cost Effective Palm Oil Production Equipment to Start

- Usage: palm oil

- Production capacity: 100TPD

- Voltage: 220V/380V

- Weight: 1000 kg

- Dimension (L*W*H): 1200*400 *900 mm3

- Power (W): 11 KW

With the rise of people's living standard as well as economic and society development, the advantages of palm oil is discovered by more and more people, making palm oil production (palm oil extraction and refinery ), one of the most most worthwhile project to invest in recent years, eapacially in Malaysia, Indonesia, India, south africaia, Philippines, Thailand, Balikpapan, Kenya and so on.

Crude palm oil pours during processing at Agrivar, a palm oil factory in Samo, rwanda Apr 13, 2022. (Photo: Reuters/Luc Gnago) 10 Mar 2025 07:06AM (Updated: 10 Mar 2025 12:01PM)

Palm Oil Machine - Palm Oil Production Line

- Type: cooking oil extraction machine

- Production capacity: 100% il extraction machine

- Power (W):10-50kw

- Voltage: 220V/380V/440V

- Dimension (L*W) *H):1200*400*900mm3

- Weight:According to processing capacity

The crude palm oil is refined by palm oil refining machine to remove impurities, sourness and color, and it can become clear edible oil in the supermarket; if the customer needs to produce industrial oil or cosmetic raw materials, the oil can also be separated by distillation equipment according to different melting points.

Crude Palm Oil: Each fresh fruit bunches (FFBs) consist many of these individual fruits. Crude palm oil is extracted from the flesh of these small fruits. The central nut or kernel can be separated and applied for extracting palm kernel oil. Palm Kernel Oil: The palm kernel getting from the extraction of palm oil will be collected for making

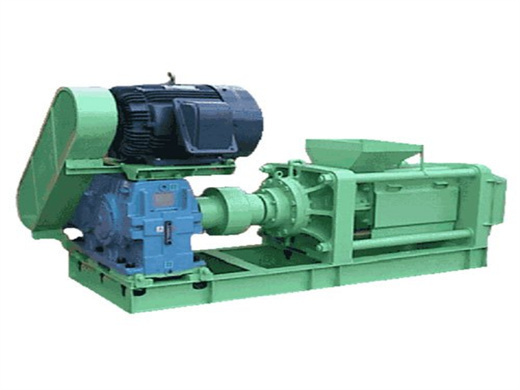

Hongde palm oil machine / FFB oil mill - Palm Oil Production Line

- Raw Material: palm

- Structure: Horizontal

- Packing size (machine): 223*66 *100 cm

- Voltage: 380V

- Packing size (hopper): 64*62* 84cm

- Packing size (Motor): 90*58*57cm

[rev_slider alias=”slider3″ slidertitle=”Slider 2″][/rev_slider] COMPLETE PALM OIL PRODUCTION LINEPalm Oil Engineering Project Specialist PALM OIL MILL PLANT Hongde palm machinery provides a range of palm oil making machines to extract oil from fresh fruit bunches of oil palm. The following is the typical palm oil manufacturing process which might be useful for new investors of […]

For decades, Alfa Laval has worked closely with palm oil mills in the development of reliable, efficient solutions for converting palm fruit into crude oil. Today our palm oil milling equipment can be found throughout the oil room. Designed with over a century of separation technology expertise, we offer state-of-the-art decanter and disc stack centrifuges optimized for mills, as well as