Sunflower Oil Extraction Process, Methods – A Full Guide

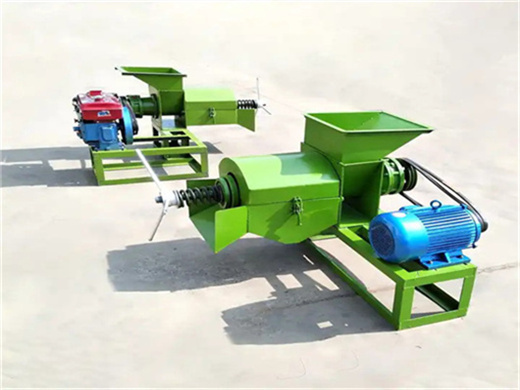

- Type: sunflower oil processing equipment

- Usage/Application: sunflower

- Voltage: adjustable

- Power (W): according to capacity

- Overseas installation: Yes

- Weight: according to capacity

- Dimension (L*W*H): 5432*2636*2345

- Country: tanzania

Cost of Sunflower oil extraction machine: Cost of automatic Sunflower oil extraction machine approximately, Rs 1.45 Lakh/Piece. Benefits of Sunflower oil. May enhance oral health. Sunflower oil is extremely useful for oil pulling. Sunflower oil reduces plaque-related gingivitis.

From Seed to Oil: Unveiling the Sunflower Oil Extraction Process

- Type: sunflower oil processing machine

- Certification: ISO CE

- Product type: cooking seed cleaning machine

- Used for: cooking seed cleaning machine

- Keyword: cooking seed cleaning machine

- Residual oil in cake: 1%

Here are the ten most frequently asked questions (FAQs) about the sunflower oil extraction process, quality, and applications, along with their answers: 1. What is the best extraction method for sunflower oil? Mechanical pressing and solvent extraction are the most common methods used for sunflower oil extraction.

The process of sunflower oil solvent extraction method includes solvent extraction, mixed oil steam distillation, wet meal decolonizing, and solvent condensation and recovery. In the sunflower oil solvent extraction method section, a chemical solvent is used to remove oil from the raw material.

A Step-by-Step Guide on How Sunflower Oil is Made

- Usage: sunflower oil

- Production capacity: according to capacity

- Voltage: 380V or 440V

- Weight: according to capacity

- Dimension (L*W*H): according to capacity

- Power (W): according to capacity

Solvent extraction is the part of the sunflower oil making process in which almost every last drop of oil is extracted from the sunflower seeds. Hexane is the most widely used solvent for this. The process begins with the pouring of hexane over the leftover cake from expeller pressing.

Learn how to extract every last drop of oil from sunflower seeds using the solvent extraction method. Discover the role of hexane, the most commonly used sol...

Sunflower Seed Preparation and Oil Extraction - ScienceDirect

- Type: cooking oil extraction machine

- Production capacity: 5-3000TPD, 5-3000TPD

- Power (W): 11 KW

- Voltage: 220V/380V or local voltage

- Dimension (L*W) *H): According to capacity

- Weight: 1000kg

The solvent extraction process utilizes a solvent that diffuses into the prepress cake granules. The extraction process is a complex combination of several mechanisms including leaching, washing, diffusion, and dialysis (Johnson, 1997). Leaching and washing remove oil that is free and easily accessible to the solvent.

The most normally used solvent is hexane which dissolves the oil out of remaining oil cake. The solvent is then distilled out of the oil, passed during the matter and then collected at the bottom. REMOVAL OF SOLVENT TRACES: Around 90% of the volatile solvent left in the extracted oil, evaporates and it’s composed for reuse.

How to extract sunflower oil from sunflower seeds?_Tech

- Raw Material: sunflower

- Production capacity:10-500 tons/day

- Weight:140 KG, 140 kg

- Voltage:380 V

- Main components :Others, gear oil

- Model:500A

The making process flow chart of sunflower oil solvent extraction plant. Both sunflower seeds and sunflower cakes that is got from sunflower oil pressing plant can be extract sunflower oil in sunflower oil solvent extraction plant. But the sunflower seeds also need pretreatment, and only the capacity is more than 30 tons per day, the engineers

It is worth noting that a plant to process rapeseed with prepressing followed by extraction will often reduce the oil content from about 40% to 20% in the presses and from 20% to 0.8% in extraction, and that (after adjustments for moisture changes during the process) the press oil produced may be roughly 25.8% of the raw seed, while the