SOYBEAN OIL QUALITY FACT SHEET - REFINING - U.S. Soy Delivers

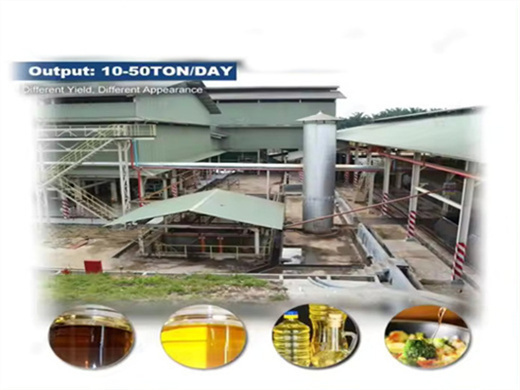

- Type: soybean oil plant

- Usage/Application: soybean

- Production capacity: 20-2000T/day

- Voltage: 380 V

- Weight: 30 tons

- Dimension (L*W*H): standard

- Power (W): 15 KW

- Country: afghanistan

Soybean Oil Refining Stages Crude degummed soybean oil (CDSBO) must be refined to produce high-quality soybean oil that is suitable for human use and many industrial uses. The traditional method to refine CDSBO is called caustic refining. This method uses a chemical process to refine CDSBO and produce refined, bleached and deodorized soybean

Soybean Oil Refining & Detailed Soybean Oil Refining Process

- Type: soybean oil refinery machine

- Automatic Grade: Semi-automatic

- Production Capacity: 1TPD-1000TPD

- Dimension (L*W*H): 1610x615x1260mm

- Power (W): According to capacity

- Voltage: 220V/380V

Soybean Oil Refining. The crude soybean oil still contains many oil-insoluble and oil-soluble impurities that needs to be removed. Soybean oil refining including degumming (removing of phosphatides), alkali refining (washing with alkaline solution to remove free fatty acids, colorants, insoluble matter and gums) and bleaching (with activated earth or activated carbon to remove colour and other

Refining crude soybean oil into refined oil | Wilmar. The resulting product is crude soybean oil. The crude oil is then refined via three stages: water degumming, chemical refining and physical refining. In water degumming, a sticky viscous oil-water emulsion or gum is removed by using water and a centrifuging process. Get Price

Phospholipase cocktail: A new degumming technique for crude

- Usage: soybean oil

- Production capacity: 80KG-200TPD automatic oil press machine

- Voltage: 220V/380V/440V

- Weight: depends on the capacity of the automatic oil press machine

- Dimension (L*W*H): depends on the capacity of the automatic oil press machine

- Power (W): depends on the capacity of the automatic oil press machine

To calculate the theoretical DAG increase, the phospholipid composition of vegetable oil should be considered. For crude soybean oil, the ranges of the PC, PE, and PI contents relative to the total phospholipids content are equal to 25–33%, 19–31%, and 10–18%, respectively (Dayton & Galhardo, 2014; Jiang et al., 2015b; Sampaio et al

soybean oil. TABLE VII gives the chemical formulas of three major phosphatides present in the crude soybean oil. Non hydratable phosphatides are present as calcium and magnesium salts. Conditions under which the seed is grown and stored and the crude oil recovered from the seed, will influence the oil content of minor constituents. VI

SOYBEAN OIL REFINERY PROCESS - Pemac Projects Pvt Ltd

- Type: cooking oil refining machine

- Production capacity: 50-200 tpd oil production

- Power (W): 15 kW

- Voltage: 220V/380V/440 V

- Dimension (L*W* H): 5432*2636*2345

- Weight: 850 KG

Soybean oil is a major vegetable oil that is used in a variety of food products, as well as in industrial applications. The soybean oil refinery process is used to remove impurities from crude soybean oil, making it safe for human consumption and suitable for industrial use. The soybean oil refinery process typically consists of the following

Soybean Oil Production Process. The production of commercial soybean oil is complicated. Below are the main steps of the soybean oil production process. Cleaning Section of Soybean Oil Production: The soybeans are first cleaned, dried and dehulled prior to oil extraction. The soybean hulls needs to be removed because they absorb oil and give a

CRUDE DEGUMMED SOYBEAN OIL | Ariyan International Inc.

- Raw Material: soybean

- Production capacity:30-500T/D

- Dimension (L*W*H):Standard

- Voltage:Standard

- Weight :Standard

- Main components:Motor, PLC

The growing demand for plant–based oils has positioned Crude Degummed Soybean Oil as one of the most widely produced and researched lipid sources globally. Origin and Processing Crude Degummed Soybean Oil is extracted from controlled, non – GMO soybeans (with GMO content below 0.9%).

Water degumming reduces the phosphorus content to less than 50 ppm with good quality crude soybean oil. The usual relation between phosphorus and phosphatide content is that phosphatides are 30 times phosphorus. The water degumming process is simple, but the crude soybean oil quality has a significant influence on the efficiency of the process.