SOYBEAN OIL QUALITY FACT SHEET - REFINING - U.S. Soy Delivers

- Type: soybean oil project

- Usage/Application: soybean

- Production capacity: 5TPD

- Voltage: 220v

- Main components: Motor

- br /Weight: 13 KG

- Dimension (L*W*H): 445*180*315mm

- Country: rwanda

Soybean Oil Refining Stages Crude degummed soybean oil (CDSBO) must be refined to produce high-quality soybean oil that is suitable for human use and many industrial uses. The traditional method to refine CDSBO is called caustic refining. This method uses a chemical process to refine CDSBO and produce refined, bleached and deodorized soybean

CRUDE DEGUMMED SOYBEAN OIL | Ariyan International Inc.

- Type: soybean oil refinery machine

- Production capacity: 65-130 Kg/h

- Voltage: 220V/380V

- Main components: Pressure container

- Weight: 880kg

- Dimension (L*W*H): 1500*1300*1550mm

As advancements in biotechnology, processing efficiency, and oil recovery continue, Crude Degummed Soybean Oil will remain a vital product with far–reaching impacts across sectors. Table 2: Chemical Characteristics of Soybean Oil Produced By Solvent Extraction . Standard Specification Of Non–GMO Crude Degummed Soybean Oil:

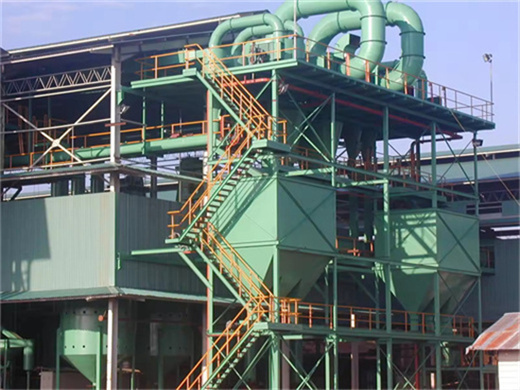

1. Superfine Fragrant Soybean Oil Refining Process. This workshop adopts the production technology of batch refining. According to the type and quality of the crude oil, the process parameters are adjusted and different refining methods are selected to produce the first and third-grade oils. The process equipment we provide has the following

Microbial Enzymatic Degumming of Crude Soybean Oil (Lecitase

- Usage: soybean oil

- Production capacity: 100TPD

- Voltage: 220/380

- Main components: motor, pressure vessel, Pump, PLC, Other, Gear, Bearing, Motor, Gearbox

- Weight: 280 KG

- Dimension (L*W*H): 1400*860*1260

To quantify the refined-oil quality during the degumming processing of crude soybean oil. 3. MATERIALS AND METHODS 3.1. oEnzymatic Degumming f Crude Soybean Oil Degumming process generally removes the major portion of phospholipids and some other sticky compounds. Although a number of parameters are involved during the water degumming process. .

Soybean Oil Production Process. The production of commercial soybean oil is complicated. Below are the main steps of the soybean oil production process. Cleaning Section of Soybean Oil Production: The soybeans are first cleaned, dried and dehulled prior to oil extraction. The soybean hulls needs to be removed because they absorb oil and give a

THE PHYSICAL-CHEMICAL MECHANISM OF THE EDIBLE OILS DEEP REFINING

- Type: cooking oil refining machine

- Voltage: 380

- Dimension (L*W*H): Standard

- Power (W): Standard

- Weight: Standard

- Certification: ISO9001

Deep degumming is a physico-chemical methods of primary edible oils refining which eliminated the acid degumming, as a dramatically method of chemical processing for remove the non-hydratable phosphatides. In deep degumming, the water pre-degummed oil is softly treated with a sequestrant agent, such as EDTA or one of its salts [7-8].

TABLE VII gives the chemical formulas of three major phosphatides present in the crude soybean oil. Non hydratable phosphatides are present as calcium and magnesium salts. Conditions under which the seed is grown and stored and the crude oil recovered from the seed, will influence the oil content of minor constituents. VI - DIFFERENT PROCESSES

Soybean Oil Refining & Detailed Soybean Oil Refining Process

- Raw Material: soybean

- Production capacity: 9-150 kg/h

- Dimension (L*W*H): 64.5* 29.5*73.5 cm

- Voltage: 110 V/220 V

- Weight: 3400 kg

- Main components: Motor

In the U.S.A. and in Europe, for soybean oil refining, the caustic soybean oil refining process is by far the most used. The physical refining of palm oil, lauric oils and other fats and oils that have a low phosphatide content by dry degumming and bleaching followed by distillation, deodorization, is 20 to 25 years old and common practice today.

What is Crude Degummed Soybean Oil? Crude Degummed Soybean Oil, an essential inedible soybean oil, undergoes a refining and hydrogenation process, removing phosphatides and making them suitable for various applications. This plant-based product is integral in the production of vegetable oils, ensuring purity and quality.