Chemical refining of sunflower oil: Effect on oil stability

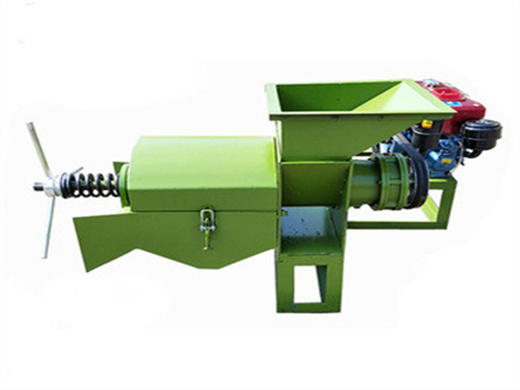

- Type: sunflower oil project

- Usage/Application: sunflower

- Production capacity: 2T/D---10T/D

- Voltage: 380v/50Hz

- Weight: as per specifications

- Dimension (L*W*H): 1360*950*1170mm

- Power (W): up to specifications

- Country: lusaka

Oleic and linoleic acid contents of canola oils obtained from each refining step were determined between 60.64% (deodorized oil) and 64.04% (neutralized oil) to 19.93% (neutralized oil) and 24.58%

Sunflower oil, Chemical refining, Physical - ResearchGate

- Type: sunflower oil refinery machine

- Production capacity: 100% cold-pressed extra virgin oil

- Voltage: 220V/380V/ 440 V

- Weight: 50tons

- Dimension (L*W*H): 48m*12M*15M(50tons)

- Power (W): 5.5-22 KW

American Journal of Polymer Science 2024, 13(1): 1-5 DOI: 10.5923/j.ajps.20241301.01 Influence of Chemical and Physical Refining Processes on Phospholipid and Total Tocopherol Content

trace metals. Neutralization is generally carried out by chemical or physical methods. Some alkalis (NaOH, KOH, NaHCO 3, Na 2 CO 3) can be used to neutralize oil for removal of the free fatty

PHYSICAL REFINING OF SUNFLOWER OIL

- Usage: sunflower oil

- Production capacity: 5TPD-100TPD, 300-400kg/h

- Voltage: 380V/50HZ/Three-phase

- Main components: Motor

- Weight: 750KG

- Dimension (L*W*H): 2280 *700*780mm

Sunflower oil has a high nutritional value, having 62-70% linoleic acid content (essential fatty acid) but on the other hand this high polyunsaturated fatty acid content makes this oil sensitive to oxidation. Crude sunflower oil, which has reached a certain level of oxidation is difficult to refine. There are two main difficulties: 1.

Bleaching. This is one the important stage in total refining process. Where the oil is heated to 100°C to 105°C and mixed with Bleaching earth chemical ( Acid Activated Clay) and also activated carbon in a vessel under vacuum at 70 mmHg where the stirring continues for specific designated time and then filtered the oil to remove the clay and carbon.

Understanding the Difference Between Physical and Chemical

- Type: cooking oil refining machine

- Voltage: 380 V

- Dimension (L*W* H): 1910*550*765 mm

- Power: 2.2 KW

- Weight: Based on the capacity of the cooking oil extractor machine

- Certification: CE,ISO9001

Suitable for High-Quality Oils: Physical refining is typically used for oils that have a low level of impurities, such as palm oil and sunflower oil. Advantages of Physical Refining : Preservation of Nutrients : Since physical refining uses less chemical intervention, it helps to preserve some of the oil’s natural nutrients, such as

Sunflower oil is used as a premium salad oil due to the presence of high ratio of polyunsaturated-to-saturated fatty acids. Refined sunflower oil has found wide acceptance because of its high polyunsaturated fatty acid content, bland flavour, good storage stability and low viscosity (Semwal et al. 1996). Refined sunflower oil has emerged as one of

SUNFLOWER OIL REFINERY - PART I - Blogger

- Raw Material: sunflower

- Production capacity: 50kg/h, 1000kg/h, 3.5-1600kg/h

- Power: 1500w

- Voltage: 220V

- Dimension (L*W*H): 760*340*470mm

- Weight: 3400 kgMain components: Motor

This project won the "Best Project" award sponsored by BP as it was a simple yet comprehensive project outlining the refinery process, mass balancing and providing a preliminary cost analysis to produce 20,000 tonnes of refined Sunflower Oil. Introduction Refining of sunflower oil is an essential industry process for removing free fatty

In sunflower oil FFA varied from 1.19 to 1.35% (w/w) in regular sunflower oil (Kreps et al., 2014), from 0.76 to 1.13% in HOHPSO (Marmesat et al., 2008) and can reach up to 4% in HOSO (Moschner and Biskupek-Korell, 2006). FFA are neutralized during the refining process in order to reduce their undesirable effects as undesirable flavor.