palm kanel expeller machins china in lusaka

- Type: palm oil expeller

- Usage/Application: palm fruit, palm kernel

- Voltage: 380 V

- Appearance: Horizontal press

- Custom: personalized

- Press series: first

- Materials: sunflower, soybeans, cooking seeds, grape seeds

- Country: lusaka

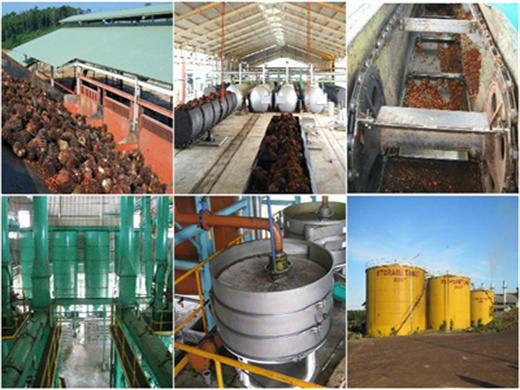

How does a palm kernel oil expeller work? The cleaned Kernels are fed to a palm kernel oil expeller machine, which consists of a main shaft and worms, which rotates within a stationary perforated cylinder called a cage or barrel. As the main shaft turns, there is a decrease in volume resulting in pressure in […]

Oil Expeller, Vegetable Oil Extraction Plant Manufacturers

- Type: palm oil processing machine

- Production capacity: 5-100TPD

- Voltage: 230V-380V-430V

- Weight: 30 tons

- Dimension (L*W*H): 20m*16m*15m

- Power (W) : 40kw/h

Manufacturer & Exporter of Mechanical Oil Extraction Plant, Solvent Extraction Plant, Cooking Oil Refinery Plant, Fish, Poultry & Animal Feed Plant, Palm Kernel & other Oil Expeller / Oil Press Spare Parts and MSW, Plastic & Industrial Shredder on Turnkey Basis.

The Palm Kernel Oil Expeller Pricelist A Comprehensive Overview In the world of oil extraction, palm kernel oil has gained significant attention due to its myriad applications and health benefits. As demand for this oil increases globally, understanding the factors that influence the pricing of palm kernel oil expellers becomes crucial for

Kumar’s Palm Kernel (PK) Series Oil Expeller Machine

- Usage: palm oil

- Production capacity: 20tpd-100%

- Voltage: 220V/380V/440V

- Main components: gear, bearing, gearbox

- Weight: 680 KG

- Dimension (L*W*H): 1970*700*780mm3

Specially designed and manufactured for maximum oil extraction from palm kernel. Minimal residual oil content in the second press cake. Independent gearbox system reduces noise level, consume less power and ensure zero contamination of mineral oil with edible oil. Alloy steel with ultrasonically tested screw shaft with heavy-duty branded bearings.

The nutcracker, kernel/shell separator and palm kernel expeller are produced to handle palm kernel. The expeller has machined flights on a single shaft with threaded backpressure cone. Generally machines are produced having a 1 tonne/hr capacity for palm oil while the palm kernel machines have rated throughputs of 150-250 kg/hr.

Palm Kernel Oil Expeller China Trade,Buy China Direct From

- Type: cooking oil extraction machine

- Production capacity: 1-1000 tons/day

- Dimension (L*W*H): According to production capacity

- Voltage: 380V

- Weight: 10000 KG

- Main components: motor, pressure vessel, pump, bearing, motor

3348 palm kernel oil expeller products are offered for sale by suppliers on Alibaba.com, of which oil pressers accounts for 92%. A wide variety of palm kernel oil expeller options are available to you, such as 20 kg/h, 50kg/h and 150 kg/h.You can also choose from automatic, semi-automatic palm kernel oil expeller,as well as from cold press, press, and cold & hot pressing machine palm kernel

Palm Kernel Expeller (PKE) is a vital by-product derived from the palm oil extraction process, renowned for its rich nutritional composition and multifaceted industrial applications. This article delves into the production methods, nutritional benefits, diverse industrial uses, sustainability considerations, and global significance of Palm Kernel Expeller, highlighting its pivotal role in

0.5-5t/H Palm Kernel Oil Expeller Press Processing Extraction

- Raw Material: palm

- Production capacity: 1TPD-1000TPD

- Power (W): 15KW

- Voltage: 220V/380V

- Dimension (L*W*H): 1.5*2.6*3.6M

- Weight: 30 tons

0.5-5t/H Palm Kernel Oil Expeller Pressing Milling Processing Extraction Machine Product Description . We are professional manufacturer of palm kernel oil milling machine,we can offer complete solutions of palm kernel oil milling to palm kernel oil refining. We manufacture unique Palm Kernel Oil Millin

The Palm Kernel Oil Extraction Machine Price is an essential part of our Grain Processing Machinery offerings.Opting for wholesale offers benefits like cost savings due to bulk orders, consistent supply for uninterrupted production schedules, and the potential for customization to match specific processing requirements.