best quality oil processing plant peanut lowest in south africa

- Type: peanut oil processing plant

- Usage/Application: peanut, groundnut

- Production capacity: 20T~50TPD

- Voltage: 220V/380V

- Weight: related to capacity

- Dimension (L*W*H): 120*100*12m

- Power (W) : according to capacity

- Country: south africa

We are a professional Peanut/Groundnut Oil Production Machine Manufacturer in China. Our company is dedicated to the design, installation, commissioning and technical training of peanut oil processing plant for 36+ years; we can provide a complete set of groundnut oil production machine turnkey projects with a processing capacity ranging from 10-5000 tons per day.

Peanut Oil Processing Plant Manufacturer - Oil Mill Plant

- Type: peanut oil processing machine

- Production capacity: 50-500 kg/h

- Voltage: 220 V/380 V

- Main components: Motor, PLC

- Weight: 1380 KG

- Dimension (L*W*H): 2150*1300* 1550 mm

So for edible oil, the pressed peanut oil needs to be extracted in the oil extraction plant before the extracted oils are sent to the oil refining plant for further processing. Big Scale Peanut Oil Plant and Small Scale Peanut Oil Processing Plant. Below are the raw materials for peanut oil, as well as the workshop of KMEC’s peanut oil plant

IMARC Group’s report, titled “Peanut Oil Manufacturing Plant Project Report 2025: Industry Trends, Plant Setup, Machinery, Raw Materials, Investment Opportunities, Cost and Revenue” provides a complete roadmap for setting up a peanut oil manufacturing plant. It covers a comprehensive market overview to micro-level information such as unit

Groundnut Oil Refining Plant | Peanut Oil Processing Plant

- Usage: peanut oil

- Production capacity: 10T-100T/D

- Voltage: 220V/380V

- Weight: 1000 kg

- Dimension (L*W*H): According to the actual situation

- Power (W) : 11KW

Neutralization reaction produced the sodium salt of fatty acids which removed through centrifugal separator and clean oil washed by hot water to remove the traces of soap. Washing: Neutralized oil treated with hot water and separated through centrifugal separator to remove the traces of soaps from neutral oil.

Above is the main peanut oil extraction methods that are widely used in commercial vegetable oil processing plant to improve the oil production efficiency and oil quality. Before starting the peanut oil extraction process, the peanut/groundnut should be pretreated to ensure high oil output.

Groundnut Oil Making Process (Peanut), Business Plan

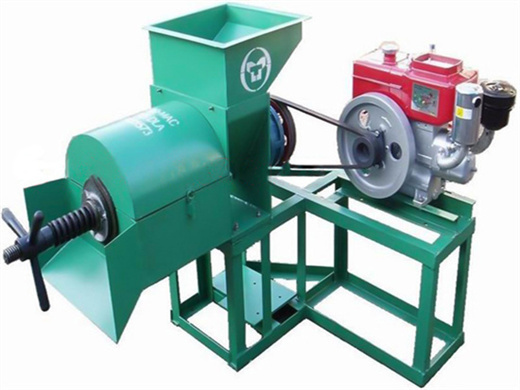

- Type: cooking oil extraction machine

- Production capacity: 40-60 kg/h

- Dimension (L*W*H): 1360*780 * 1200mm

- Voltage: 220 V/380 V

- Weight: 290 KG

- Main components: Motor

The crude peanut oil or Groundnut oil that is filtered by the oil filter machine is pure and clean. But it still contains several oil-soluble and in oil-soluble impurities. Therefore, it is essential to equip the peanut oil production plant with professional edible oil refinery equipment to get them off and obtain the refined high-quality

Groundnut oil, also called peanut oil or Arachis oil, is extracted from the peanuts and consumed as edible oil all over the world. Mostly, edible groundnut oil is used in Asian and African countries to add flavor or aroma to the food. With development of groundnut oil extraction technology and method, groundnut oil processing plant cost is relatively cheaper than before, the price of groundnut oil in the market is now affordable for most people.

peanut oil purification disc bowl quality 3 in south africa

- Raw Material: peanut

- Production capacity: 200~2000T/D

- Power ( W): 7.5 kW

- Voltage: up to specification

- Dimension (L*W*H) : 2050*1350*2000Weight: 1000kg

- Function: fresh palm bunch oil processing machine

Vegetable oil: Colza oil, cottonseed oil, Corn oil, palm oil, soybean oil, Peanut oil, Rice oil, Sesame oil, Safflower oil and son on. Animal oil: fish oil and other various animal fat clarification. Product competitive advantage: 1, High rotating speed 2, Operating stability 3, Completely sealed up of the inlet and outlet system 4, Lower noise

Simple operation and high pressure ensures continuous processing. The high temperature peanut oil press machine enables high oil yield during oil pressing process. Owing to the most scientific equipment configuration, the final peanut oil product is available in high capacity, high purity and low residual oil.