How Coconut Oil Is Made: The Surprising Truth & Process

- Type: peanut oil processing plant

- Usage/Application: peanut, groundnut

- Production capacity: 100%

- Voltage: 220V/380V

- Weight: 30 tons

- Dimension (L*W*H): 48m*12M *15M(30TPD)

- Power (W): 22kw

- Country: afghanistan

The journey of coconut oil production progresses with the heating of either the freshly extracted coconut milk or the dried coconut meat known as copra. In the wet mill method, the coconut milk is gently heated, allowing the lighter oil molecules to separate and rise to the top, a process that can be enhanced by fermentation or other separation

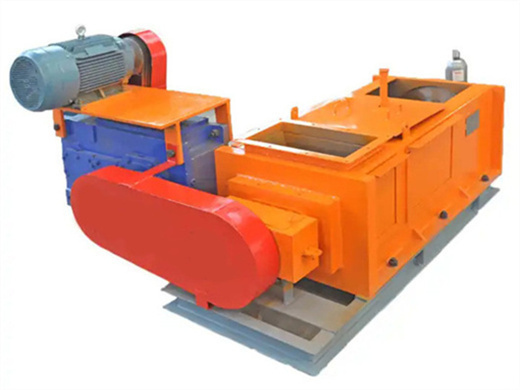

Oil Mill Machinery for Oilseeds Processing Plant

- Type: peanut oil processing machine

- Production capacity: 98%-100%

- Voltage: 220V/380V/440V

- Certification: CE,ISO

- Dimension (L*W*H): 1200*400*900mm3

- Power ( W): According to up to capacity

GOYUM has designed, manufactured, supplied, installed and commissioned more than 750 Oil Extraction Plants in over 60 Countries covering 6 Continents for crushing oil seeds and nuts such as Soybean / Soya bean, Cottonseed, Groundnut / Peanut / Earthnut, Palm Kernel, Sunflower Seeds, Shea Nut, Mustard Seeds, Copra / Coconut, Sesame Seeds, Cashew Nut Shell, Rapeseed / Canola Seeds, Neem Seed

1.8 in coconut oil and about 11.6 in palm kernel oil. The determination of this ratio will add extra support to assess any adulteration of palm kernel oil into pure refined coconut oil or virgin coconut oil, which is analysed by fatty acid composition data alone. The total tocopherols content of coconut oil

Coconut Oil Manufacturing Process Flowchart

- Usage: peanut oil

- Certification: CE/ ISO/ BV

- Automatic Grade: Palm extract manufacturer

- Power (W): 15KW

- Voltage: 220V / 380V / 440V

- Production capacity: 100-4000TPD

Here are some business opportunities in coconut oil production business at many places around the world including India, Indonesia, Philippines, south africaia and Africa. Equipment & Machinery for starting Coconut oil Manufacturing business: Here are the important coconut oil manufacturing plant machines you need to start an oil manufacturing business:

Peanut oil (groundnut oil), as a kind of light yellow transparent edible oil with a pleasant fragrance and good taste, is relatively easy to digest. Peanut oil contains more than 80% unsaturated fatty acids (including 41.2% oleic acid and 37.6% linoleic acid).

Peanut Oil Production Plant Investment Costs Analysis

- Type: cooking oil extraction machine

- Voltage: 220V/380V

- Dimension (L*W*H):Standard

- Power (W):Standard

- Weight :Standard

- Certification:CE ISO

The general capacity we can provide for peanut oil processing plant ranges from 5 to 400 tons per day. Taking the smallest peanut oil production line (5TPD) as example, the totally investment for a complete automatic peanut oil production line is $ 8,500 around (Not include the oil refining equipment). Please note all the equipment included in

So for edible oil, the pressed peanut oil needs to be extracted in the oil extraction plant before the extracted oils are sent to the oil refining plant for further processing. Big Scale Peanut Oil Plant and Small Scale Peanut Oil Processing Plant. Below are the raw materials for peanut oil, as well as the workshop of KMEC’s peanut oil plant

What is the Process of Coconut Oil Manufacturing?

- Raw Material: peanut

- Production capacity: 98%-100%

- Power (W): 22kw

- Voltage: 380V/50HZ

- Dimension (L *W*H): 48m*12M*15M(30TPD)

- Weight: 10 tons

Coconut oil can be extracted through "dry" or "wet" processing method. Dry manufacturing method for the coconut oil manufacturing process requires the meat to be extracted from the shell and dried using fire, sunlight, or kilns to create copra.The copra is pressed or dissolved with solvents, producing the coconut oil and a high-protein, high

The peanut oil production line is the extraction process of fragrant oil from peanut kernel by adopting the unique pressing technology. Peanuts are high-oil-containing oilseeds. Currently, the unique pressing processes are suited to extract high-flavored edible oils, which has really achieved “no chemical production”.