Understanding coconut as a biomass fuel (EN-V2.2-2021.11.11)

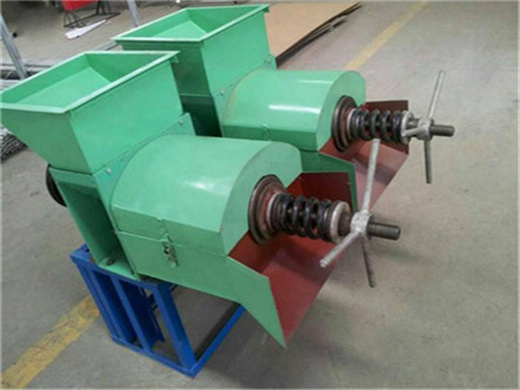

- Type: coconut oil press

- Usage/Application: coconut, copra

- Production capacity: 10TPD

- Voltage: 380 V

- Oil type: cooking oil

- Main components: motor, gear

- Weight: 2000 KG

- Country: mozambique

a variety of coconut wastes and has been operating successfully since April 2015. The Challenges of Coconut Waste There are many handling and processing challenges in using coconut wastes as a biomass fuel. Each type of coconut residue (husk, shell, bunch, fronds, leaves and trunk) has di˜erent physical and chemical properties.

Production of Fuel Briquettes from Waste Paper and Coconut

- Type: coconut oil processing machine

- Automatic grade: Semi-automatic

- Production capacity: 1TPD-1000TPD

- Dimension (L*W*H): 46*32*36cm

- Power (W): 5.5 kW

- Voltage: 220V

a municipal solid waste and an agricultural residue, i.e., shredded waste paper and hammer-milled coconut husk particles. Briquettes were manufactured using a manually-operated closed – end die piston press at an average pressure of 1.2 x 103 N/m2 using four coconut husk: waste paper

Biofuel production from coconut biomass has become a viable approach to addressing the environmental challenges associated with coconut residue disposal (Sohaib et al., 2017, You et al., 2019). While biofuel has the potential to exist as gas (syngas), liquid (bio-oil), or solid (biochar), the primary focus of this study is the production of

A Review of Pellet Production from Biomass Residues as

- Usage: coconut oil

- Production capacity: 450-500kg/h; 10-12T/24 hours

- Voltage: 380v, 380v

- Main components: Motor

- Weight: 780KG

- Dimension (L*W*H): 201*80*138cm

Hence, previous research on the production of pellets and application as domestic fuel will include both pellets and briquettes from wood and agricultural residue. Gravalos et al. (2010), conducted an experimental study on calorific energy values of biomass residue pellets for heating purposes. The fuel samples used, were biomass

Pure Coconut Oil in Modified Engines Because copra oil has a much higher viscosity than regular diesel, the main modification needed is a fuel heater. This would heat the oil prior to injection allowing for the fuel and engine coolant to cross flow and would thus eliminate harmful deposits on the engine.

A Review of Pellet Production from Biomass Residues as

- Type: cooking oil extraction machine

- Voltage: 220V/380V

- Dimension (L*W*H): 1610x615x1260mm

- Power (W): According to capacity

- Weight : 1050 KG

- Steam consumption: ≤280Kg /T

In a study “Characterization and feasibility of biomass fuel pellets made of Colombian timber, coconut and oil palm residues regarding European standards”, Carlos et al. (2012), assessed the main properties of Colombian timber industry residues, coconut shells and oil palm shells and compare the characteristics of pellets made from these

Coconut is widely cultivated in Vietnam, Indonesia, Thailand, India and other countries in Southeast Asia and South America for a variety of products including copra and coconut oil. The present study reports on the physical and chemical properties of fuel pellets from coconut biomass (stem and fronds).

Coconut Shell as a Promising Resource for Future Biofuel

- Raw Material: coconut

- Production capacity: 93%

- Dimension (L*W*H): 1570 *570*1320mm

- Voltage: 220V/380V

- Weight: 550 KG

- Main components: motor, bearing

In 2013, production of Bioethanol from coconut oil accounts for 5.4% coconut oil consumption around worldwide (Moss et al. 2010). At present, sugar crops are paying more attention in the manufacturing of Bioethanol (Kocar and Civa 2013). Pure ethanol can be used as a fuel for transport system, but it is frequently used as a preservative of

Biofuel production from coconut biomass has become a viable approach to addressing the environmental challenges associated with coconut residue disposal (Sohaib et al., 2017, You et al., 2019). While biofuel has the potential to exist as gas (syngas), liquid (bio-oil), or solid (biochar), the primary focus of this study is the production of