Cold press in oil extraction. A review - ResearchGate

- Type: peanut oil press

- Usage/Application: peanut, groundnut

- Production capacity: 5TPD-100TPD

- Voltage: AC220V,50HZ

- Main components: motor, gear

- Weight: 13 KG

- Dimension (L*W*H). ): 100x85x100cm

- Country: tanzania

PDF | On Dec 1, 2018, Büşra Çakaloğlu and others published Cold press in oil extraction. A review | Find, read and cite all the research you need on ResearchGate. w alnut, a nd peanut oils.

Cold pressed peanut (Arachis hypogaea L.) oil - ScienceDirect

- Type: peanut oil processing machine

- Production capacity: 1-1000TPD

- Voltage:220V/380V/415V

- Weight: According to the actual situation

- Dimension (L*W*H): According to the capacity

- Power ( W): 1-30kw

Commercial cold pressed extraction of peanut oil is carried out using a twin-screw press at temperatures below 60°C (Wang, Liu, Hu, et al., 2016; Zheng, Ren, Su, Yang, & Zhao, 2013). Lastly, a frame filter is used to press and filter three times under 30°C to obtain the cold pressed peanut oil (Wang, Liu, Hu, et al., 2016). Cold pressing of

To commercially extract cold-pressed peanut oil, a twin-screw press is used, and the pressing is performed at specific temperatures that do not exceed 60 °C. The oil yield was not evaluated in this study, but the researchers were very interested in utilizing the by-product of this extraction (i.e., the meal), knowing that 70 kg of PDPM was

Is Peanut Oil a Cold Pressed Oil? The Ultimate Guide to

- Usage: peanut oil

- Production capacity: 450-500kg/h

- Voltage: 380v

- Oil type: Cooking oil

- Main components: Motor, pump, gearbox

- Dimension (L*W*H): 2350X1650X1930<br /Weight: 2100 KG

1. Cold Pressed Peanut Oil. Cold pressed peanut oil is extracted using the method described above, ensuring that the oil retains its natural nutrients and flavor. This type of oil is often labeled as “cold pressed” or “raw” on packaging. 2. Refined Peanut Oil. Refined peanut oil is obtained through a two-step process involving:

The conditioned peanut kernels are transported by a conveyor to the twin-screw press for cold pressing; the cold-pressed crude oil and cold-pressed peanut meal with low denaturation will be obtained. After the cold-pressed crude oil is filtered with frame filter, product oil is obtained, which will be packaged by a filling machine to form cold

Editorial: Cold Pressed Oils: A Green Source of Specialty Oils

- Type: cooking oil extraction machine

- Production capacity: 98%

- Voltage: 220V/380V/440V

- Weight: 1200kg

- Dimension (L*W*H): 1700*1100*1600mm

- Power ( W): 7.5 kW

The need for widely usable bioactive lipids and natural antioxidants continues to grow. Methods used for oil extraction may alter minor constituents that have functional properties and contribute to oil stability. In recent years, consumer demand for cold pressed oils as an alternative to conventional products has increased.

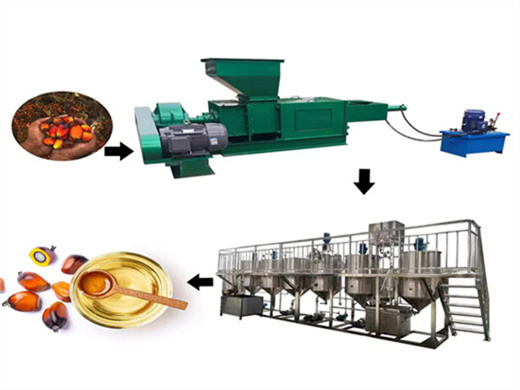

for oil extraction from oilseeds with oil content below 20% [4]. Pressure is used in the separation of the mentioned phase separation. And depending on whether or not the temperature is applied, it is called hot or cold press extraction [5]. Cold press machine has one inlet that seeds were feed and two exits that obtained oil

(PDF) Defatting and Defatted Peanuts: A Critical Review on

- Raw Material: peanut

- Use: cooking oil

- Automatic grade: oil extraction plant of seeds for cooking

- Certification: ISO CE

- Production capacity: 100 tons of oil per day

- Voltage: 380V, Adjustable

frying of peanuts before they are cold-pressed, with the resulting peanut oil then being filtered [ 20 ]. In 2017, Chen et al. examined the effects of pressing temperature and moisture content,

Peanut oil pressing methods. Divided by pressing temperature, there are two types of peanut oil pressing methods they are hot pressing technology and cold pressing technology. Hot pressing method is the traditional process of peanut oil. Peanut oil is steamed fried and pressed, generally at a temperature above 120 ℃ with a high rate of oil