Cold pressed soybean oil - ScienceDirect

- Type: soybean oil press

- Usage/Application: soybean

- Production capacity: 10T~100TPD

- Voltage: 220V/380V

- Weight: related to capacity

- Dimension (L*W*H): 80*100*12m

- Power (W) : according to capacity

- Country: pakistan

It is reported that the total phytosterol content of cold pressed soybean oil (3.2 mg/g) is close to that of cold pressed flaxseed (3.1 mg/g), and sunflower (3.2 mg/g) oils, and less than that of cold pressed corn (9.7 mg/g), and rapeseed (7.7 mg/g) oils (Rudzińska et al., 2001).

Editorial: Cold Pressed Oils: A Green Source of Specialty Oils

- Type: soybean oil processing machine

- Certification: ISO CE

- Product type: oil mill machinery prices

- Solvent: n-hexane

- Keyword: oil mill machinery prices

- Residual oil in cake: 1%

The need for widely usable bioactive lipids and natural antioxidants continues to grow. Methods used for oil extraction may alter minor constituents that have functional properties and contribute to oil stability. In recent years, consumer demand for cold pressed oils as an alternative to conventional products has increased.

for oil extraction from oilseeds with oil content below 20% [4]. Pressure is used in the separation of the mentioned phase separation. And depending on whether or not the temperature is applied, it is called hot or cold press extraction [5]. Cold press machine has one inlet that seeds were feed and two exits that obtained oil

Cold press in oil extraction. A review - ResearchGate

- Usage: soybean oil

- Model NO.

- SRP222

- Certification

- First class

- Press series

PDF | On Dec 1, 2018, Büşra Çakaloğlu and others published Cold press in oil extraction. A review | Find, read and cite all the research you need on ResearchGate

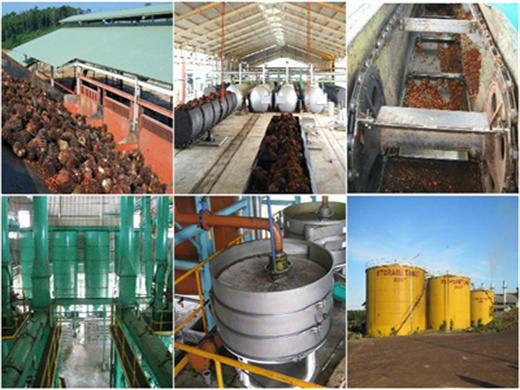

Soybean Oil Extraction Technology illustration. Usually, when the processing capacity of oilseeds is more than 20 tons/day, the extraction methods can be selected to produce soybean oil, which can reduce the production cost of soybean oil and obtain more profits. The Difference Between Soybean Oil Extraction Methods and Pressing Methods

Soybean Oil: Production Process, Benefits and Uses in

- Type: cooking oil extraction machine

- Production capacity: 150(kg/h)

- Voltage: 380V

- Main components: motor, pressure vessel, PLC, gear, bearing, gearbox

- Weight: 2000() () () KG

- Dimension (L*W*H): 1100*1000*1750(mm)

contamination. Before storage the crude soybean oil has to be sampled and analyzed. After receiving, crude soybean oil transferred to the storage tanks. Those tanks must be constructed to provide proper isolatio n from other oils as contaminants. Degumming is the first processing step for soybean oil which has high amount of hydratable

However, other countries have different requirements for their cold pressed oils. For example, the British Association of Cold Pressed Oil Producers (BACPOP) says cold pressed oils that adhere to their standards are produced at 40 C (104 F) or lower. If you buy imported olive oils or other products, be aware that these oils may be cold pressed

The difference between pressed soybean oil and solvent

- Raw Material: soybean

- Automatic grade: semi-automatic

- Voltage: according to requirement

- Production capacity: 200t-2000t per day

- Power (W): according to capacity

- Dimension (L*W*H): 1200*400*900mm3

Pressing and solvent extraction are commonly used for soybean oil extraction to extract crude soybean oil. After refining the crude soybean oil, edible refined oil can be produced. ressed soybean oil, also known as cold-pressed soybean oil, is produced by pressing or crushing the soybeans without using any chemicals or solvents.

Occurrence data of GE and 3-MCPDE concentrations in refined oils (n=25) and pressed oils (n=26) marketed in Taiwan showed that hot-pressed oils had higher concentrations than their cold-pressed