Expeller-Pressed vs Cold-Pressed Oil - Goodnature

- Type: cottonseed oil expeller

- Usage/Application: cottonseed

- Production capacity: 80-800 kg/h-99%

- Voltage: 1.1 kw

- Core Components: motor, motor, hydraulic system

- Weight: 590 KG

- Dimension (length*width*height): 600* 880*1150 mm

- Country: zambia

Always search for a label that says “unrefined oil,” or search for either “expeller-pressed” or “cold-pressed” to understand the pressing process and extraction method. If you’re interested in making your own Cold-Pressed Nut Oil, try our recipe created by our Goodnature Chef and consultant, Ari!

Cold Press Expellers, Cold Press Expeller, Cold Press

- Type: cottonseed oil processing machine

- Production capacity:200kg/h-2000kg/h-100%

- Voltage:According to capacity

- Main components:Motor, pressure vessel, pump, PLC, gear, bearing, motor, gearbox

- Weight:1000 KG

- Dimension (L*W*H): According to capacity

The cold press expeller works in the rotary manner, hence it is also known as the rotary cold press expeller. The cold pressed oil has been used in Asia and Pacific over thousands of years ago. This method is very appropriate for expelling oil from oil seeds like white and black sesame, coconut, almond, mustard, rapeseed and peanut from the oil.

A well-stocked pantry includes a selection of different culinary oils, but deciding which types are best for your cooking needs may seem a little tricky. The difference between cold-pressed and expeller-pressed oils comes down to how the oils are extracted. Cold-pressed oils are ideal when pure, unaltered taste is a must.

Difference Between Solvent Expelled, Expeller Pressed & Cold

- Usage: cottonseed oil

- Production capacity: 5TPD-100TPD

- Voltage: 380V/50HZ

- Main components: Motor, Motor

- Weight: 3KG

- Dimension (L*W*H) : 270*260*350*60mm

Cold Pressed Process. Cold pressed seed oils must be produced below 122˚ F (as is legally defined in Europe) and should only apply to fully unrefined oils that are not heated later during the refining process. The term “cold pressed” has sometimes been improperly used to describe expeller pressed oils, but these are really two different

The issue with high temperatures, as we mentioned before, is that they change the flavor of the oil. Which brings us to the term "cold pressed". Some companies go to great efforts to maintain a temperature below 90 degrees Fahrenheit when pressing the oil. In Europe the term "cold pressed" is regulated and oils cannot exceed that temperature.

Oil Extraction Methods: Expeller vs. Cold Pressed & More

- Type: cooking oil extraction machine

- Production capacity: 10-5000T/D

- Voltage: 220V/380V/440V

- Weight: 420 KG

- Dimension (L*W*H): 1910*550*765 mm

- Power: 2.2KW

Expeller pressing removes about 87-95% of the oils from the nuts/seeds, making it the second most efficient. Cold Pressed Oils Cold-processed oils cannot exceed 122°F during the extraction process. This means that vs. expeller pressed, a cold-pressed oil extraction method allows for the natural enzymes to stay intact and maintains a higher

Cold-pressed oils: Extracted using minimal heat to retain maximum nutrients and antioxidants. Expeller-pressed oils: Use high pressure and heat, which can reduce nutrient content. Solvent-extracted oils: Often rely on chemicals to pull oil from seeds, which may leave chemical residues.

Expeller Pressed Vs Cold Pressed Oils - Castor Oil Guide

- Raw Material: cottonseed oil

- Production capacity: 10-5000T/D

- Power: 2.2 KW

- Voltage: 220V/380V/410V

- Dimension (L*W*H): 1910*550*765 mm

- Weight: 420 KG

Expeller Pressed Vs. Cold Pressed 1. Temperature Profile. Expeller-pressed oil is extracted using mechanical pressure with temperatures that may rise due to friction, while cold-pressed oil is extracted at temperatures below 120 degrees Fahrenheit to preserve nutrients. 2. Processing Method

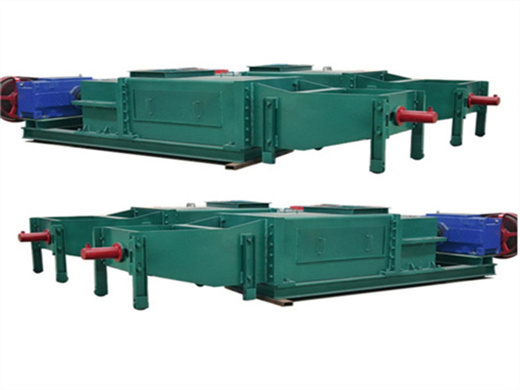

A Cotton Seed Oil Expeller is a machine designed to extract oil from cotton seeds using mechanical pressure. Operating with mechanical efficiency, it ensures a thorough extraction process without the use of heat or chemicals. The resulting cotton seed oil maintains its natural properties, making it suitable for various applications.