Complete Equipment and Machinery for Cottonseed Oil Mill Plant

- Type: cottonseed oil refinery machine

- Usage/Application: cottonseed

- Production capacity: 98%

- Voltage: 220 V/380 V/440 V

- Weight: 700kg

- Dimension (L*W*H): 1400*600*600mm

- Power ( W): 1.5 kW

- Country: ghana

30ton/day Cottonseed Oil Refinery Plant. Refining crude cottonseed oil to produce edible / cooking oil. It involves bleaching, De-acidification, deodorization, and degumming. Fractionation can get solid and liquid oil through solid and liquid separation and cooling crystallization. Read more about our 30TPD Cottonseed OIl Refinery

BEST Cottonseed Oil Mill Machinery with Cheap Price

- Type: cottonseed oil refinery machine

- Production capacity: 450 kg/h

- Voltage: 380v

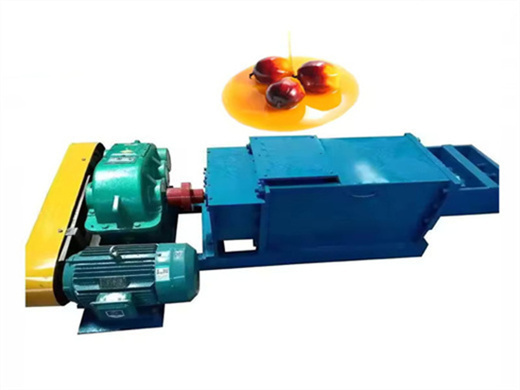

- Main components: motor, gear, Bearing, motor, gearbox, spiral juicer

- Weight: 1800 KG

- Dimension (length x width x height): 2250*1800*2700 mm

Cotton Seed Oil Refining and Fractionation Project. Our Machinery is a pioneer manufacturer of oil processing machine and complete equipment, established in 1997. We can offer all kinds oil oil machinery including oil mill, filter press, oil refinery machine and so on.

For food processing or other purposes, the crude oil should be refined to remove non-triglyceride materials and other impurities. This process is called Edible Oil Refinery. The detailed cottonseed oil refinery process is as below. 1~20TPD Small Cottonseed Oil Refining Machine for Sales

Turn-key Oil Milling/Pressing Plant, Oil Extraction

- Usage: cottonseed oil

- Production capacity: 1 ton/day

- Voltage: 280V/380V/440V

- Guarantee: One year warranty against manufacturing defects.

- Weight: 0 KG

- Dimension (L*W*H) : 4.26 *1.55 * 3.52 ft

We are experienced in building oilseed processing plant, oil milling plant, mechanical oil pressing line, solvent extraction plant and oil refining plant.View our website to find detailed information about KMEC oil mill plant, oil seed processing equipment, oil extraction machine, oil filtering machine other related oil mill machinery.

Cotton Seed Oil Refinery Plant. Oil Refining is the progress of removing impurities such as phospholipids, FFA, pigment, and off-flavor in cruel oil before edible application. An oil refining machine is used for producing the first or second-grade edible oil. We are able to supply the professional oil refining plant and related oil refining

Refined Cotton Cellulose Production Line

- Type: cooking oil refining machine

- new oil solvent extraction machine

- Capacity: according to the requirements of the machine oil solvent extraction

- Color: according to the requirements of the oil solvent extraction machine

- Oil material: peanut, soybean, palm oil cake, etc.

- Equipment material: stainless steel

Dingsheng Machinery has cooperated with refined cotton producers since the beginning of the industry. Our experience has been applied to smart cottonseed oil and cottonseed deep processing solutions for the entire supply chain - cottonseed oil refining, cottonseed oil hydrogenation, refined cotton cellulose, cottonseed protein and more.

Complete set cottonseed oil processing machine are generally divided into three processes, They are: cottonseed oil pretreatment and pre-pressing machine, cottonseed oil solvent extraction plant and cottonseed oil refinery plant. Here we focus on introduction the cottonseed oil processing process, which from cottonseeds to crude cottonseed oil and refined cottonseed oil.

Mini/Small Complete Cotton Seed Oil Machinery

- Raw Material: cottonseed oil

- Voltage: up to specification

- Dimension (L*W*H): 1360*950*1170mm

- Power (W): up to specification

- Weight: according to specification

- Certification: ISO9001

Mini/Small Complete Cotton Seed Oil Processing Machinery. Cottonseed Oil Production Line Supplier. Generally, when talking about cotton seed oil production, we think about mechanical pressing method. Actually, there is another methods called solvent eatrxtion which adopts orgalic solvent to extract the oil out, which is at cheaper price.

Cotton seeds need careful cleaning and processing. Firstly, they need to be properly dried and separated from dust, leaves and other contaminants. Then comes the most important pretreatment: removing gossypol from cotton seeds, because gossypol is poisonous. This process may sound complicated and hard to handle. But don’t worry, as you can grow genetically modified cotton and avoid this trouble.