Peanut Oil Making Machines for Sale

- Type: peanut oil processing machine

- Usage/Application: peanut, groundnut

- Production capacity: 5TPD-100TPD

- Voltage: 220V/50HZ three-phase

- Main components: Engine, motor

- Weight: 27.1KG

- Dimension (L*W*H): 1055*805*345mm

- Country: afghanistan

The oil content of peanut is approximately 42% to 52% oil. Peanut oil is mainly used for cooking purpose as it contains lots of protein and 80% unsaturated fatty acids like oleic acids and linoleic acids. Peanut oil is in light yellow transparent color and has a fragrant smell, and their taste is very delicious. Groundnut / Peanut Oil Making

Manufacturer & Supplier of Efficient Peanut Oil Press

- Type: peanut oil processing machine

- Production capacity: 50-100 tons per day

- Dimensions (L*W*H): 3.40 x 1.80 x 2.00

- Main components: motor, gear, bearing, motor, gearbox

- Warranty: 1 year, 1 year

- Weight: 3500 KG

We are a professional enterprise focusing on the research and development, production and sales of peanut oil processing equipment, providing customers with a full range of products and services. Our products range from small peanut oil presses to large industrial peanut oil production lines to meet the needs of customers of different sizes.

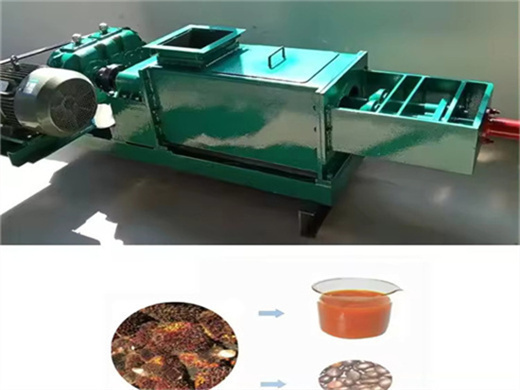

This screw peanut oil extraction machine is an efficient and energy-saving oil processing equipment, which is widely used in the pressing of various oil crops such as peanuts, soybeans, sunflower seeds, etc. The equipment adopts advanced screw extrusion technology to extract oil from oil by physical pressing, which not only improves the oil

Peanut oil processing machine - edible oil extraction machine

- Usage: peanut oil

- Production capacity: 3.5-6.5 tons/day

- Voltage: 380v

- Main components: Motor, Motor

- Weight: 700 KG

- Dimension (L*W*H): 2000*700* 1900mm

The common capacity is of 3TPD, 6TPD, 10TPD, 15TPD, 20TPD, 30TPD,50TPD,60TPD and so on. What’s more, we can customized peanut oil processing machine according to the customer requirements. Complete set of peanut oil processing plant. Application of peanut oil processing machine:

In the ever-evolving world of nut processing, the Peanut Oil Press Machine emerges as a prime example of advancement and efficiency. This state-of-the-art machine leverages electrical type technology to streamline and enhance the extraction of superior quality peanut oil, thus positively impacting the consumption of peanut oil.

Fully Automatic Groundnut/Peanut Oil Production Line

- Type: cooking oil extraction machine

- Main components: Motor

- Power: 0.75 kw

- Voltage: 220 V/380 V

- Weight: 180 kg

- Dimension (length x width x height): 890*550*765 mm

What parts are included in a peanut oil screw press? Peanut oil screw press mainly consists of five parts: hopper, gear box, press chamber, press screw and frame. Among them, the press screw is the key of the whole peanut oil screw press, and the choice of its material will affect the quality and service life of the press. 2024-08-26

Our Machinery is the expert of peanut oil making machine. We specialized in designing and manufacturing small peanut oil making machinery and complete peanut oil processing plant with high efficiency and low cost. It is always true that quality is the core competitiveness of any products, and we treat the quality of our oil making machine at

peanut oil press machine for sale/large peanut oil processing

- Raw Material: peanut

- Production capacity: 100% sunflower oil manufacturer

- Power (W): 10-50kw

- Voltage: 220V/380V/440V

- Dimension (L*W*H): Depends on its capacity

- Weight: Depends on its capacity

Peanut oil press machine is a kind of oil pressing machine that squeezes peanuts into peanut oil. In commercial production, it can use a screw and hydraulic peanut oil expeller machine to extract peanut oil. It can not only produce oil through a single machine, it can also produce through a large-scale peanut oil production line.

GOYUM 2400 is a powerful and robust oil processing machine specifically designed to handle high-volume oil extraction operations. This machine is commonly used in commercial or industrial where there is a need for large-scale oil production. They are engineered to efficiently process significant quantities of oilseeds or nuts, ensuring high