Mechanical Methods of Oil Extraction from Peanuts

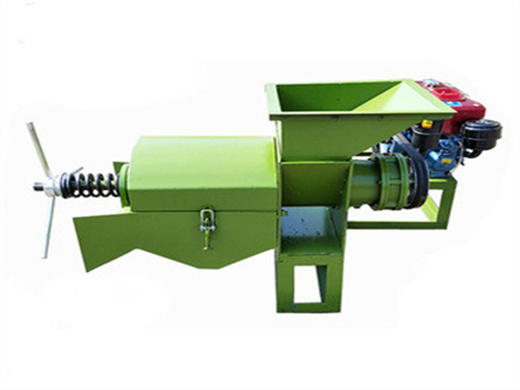

- Type: peanut oil extraction machine

- Usage/Application: peanut, groundnut

- Production capacity: 100%, 5T-200T per hour

- Voltage: 380V/50HZ, 380V /440V or local voltage

- Weight: 1200kg, According to capacity

- Dimension (L*W*H): 1700*1100*1600mm, According to capacity

- Power(W): 15KW , According to capacity

- Country: lagos

Peanuts, being crucial crops of global importance, have gained widespread recognition for their versatility and nutritional value. In addition to direct consumption, either with or without treatment, peanuts can be the subject of diverse applications focusing mainly on two distinct objectives: oil extraction and defatting processes.

The evaluation of extraction of some nut oils using screw

- Type: peanut oil processing machine

- Voltage: 380

- Power (W):Standard

- Certification:ISO9001

- Weight:Standard

- Dimension (L*W*H):Standard

From the pressing of oils, it is seen that the oil yield decreased when pressing speed increased (from 30 rpm to 90 rpm, for example in walnut from 0.36 kg to 0.16 kg.h-1) and that the oil

nutritional value. In addition to direct consumption, either with or without treatment, peanuts can be the subject of. diverse applications focusing mainly on two distinct objectives: oil extraction and defatting processes. Mechanical techniques for oil extraction from peanuts are grouped into three main sections: extrusion and screw pressing, cold

(PDF) Defatting and Defatted Peanuts: A Critical Review on

- Usage: peanut oil

- After-sales service: 2 years

- Warranty: 2 years

- Voltage: 220V

- Press series: as description

- Structure: Vertical

In addition to direct consumption, either with or without treatment, peanuts can be the subject of diverse applications focusing mainly on two distinct objectives: oil extraction and defatting

processing most widely used is the peanut oil. The peanut cake or meal obtained after oil extraction which can be full fatted, partially defatted or defatted is later used as flour, isolates and concentrates [6]. Oil extraction from the peanut kernel is a well-established industrial since the early 1950s. They have thus supported in

Maximize Profits with Peanut Oil Extraction - Anderson

- Type: cooking oil extraction machine

- Production capacity: 100 tons/day

- Voltage: 110 V/220 V

- Main components: motor, gear

- Weight: 100 kg

- Dimension (L*W*H)): 42*16*285

Peanut oil extraction. Oil is crushed from cooked, dried peanut material in a screw press or oil expeller, which uses the mechanical force of a revolving barrel to squeeze the oil from the solid meal. Peanut’s high oil content requires double pressing to obtain maximum oil yields since the meal may still contain up to 14-20% residual oils

The leaching procedure mainly makes use of the solid-liquid extraction principle to select certain fat-dissolving organic solvents to extract the peanut oil. Generally speaking, the leaching solvent should meet the following conditions: good fat solubility, stable physiochemical properties, easy separation from the fat and meal, and be safe

Peanut Oil - an overview | ScienceDirect Topics

- Raw Material: peanut

- Production capacity: 20-1000T/D canola oil pressing machines

- Power (W): Capacity

- Voltage: match with local voltage, math with local voltage

- Dimension (L*W*H): according to the capacity of oil pressing machinery of canola

- Weight: 1000 kg

Peanut oil is extracted by employing hydraulic presses and expellers, and the method of solvent extraction. Peanut oil is rich in oleic, palmitic, and linoleic acids and possesses good oxidative stability. Aflatoxins, often present in raw contaminated peanuts, should preferably be absent in refined oil or within the legally permitted level.

Growing sesame in well-spaced rows leads to an increase in the number of capsules/plant and the number of seeds/capsules, seed weight and oil content (Olowe and Busari, 2003; Roy et al., 2009). However, narrow row cultivation has also been reported to increase seed yield and reduce weed density due to faster canopy closure ( Harder et al