Cottonseed Oil Production Line

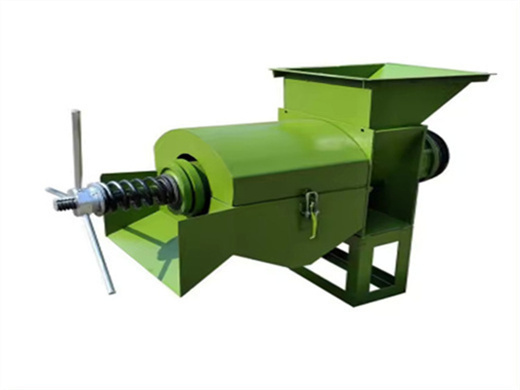

- Type: cottonseed oil making machine

- Usage/Application: cottonseed

- Production capacity: 1-100T/DAY

- Voltage: 0

- Warranty: 1 year, 18 months

- Weight: 70 KG

- Dimension (L*W*H): 55*35*75cm

- Country: afghanistan

Cottonseed contains a kind of glyhol that is harmful to the human body. Whether it is squeezing or leaching cottonseed oil, it must be must be refined. Dingsheng Machine provides three types of cottonseed oil refining equipment: batch refining equipment, semi-continuous refining equipment of cottonseed oil, and full continuous refining equipment.

Manufacturer, supplier of Cottonseed oil processing machine

- Type: cottonseed oil refinery machine

- Voltage: 380 V

- Appearance: Horizontal

- Customized: Customized

- Press Series: Second

- Press materials: Oilseeds

Complete set of cottonseed oil making machine. Application of cottonseed oil processing machine: Cottonseed oil processing machine designed by our factory is the advanced edible oil processing machinery, characterized by the high oil output rate with good quality, simple design, easy to use and continuous operation.

Dingsheng Machinery has cooperated with refined cotton producers since the beginning of the industry. Our experience has been applied to smart cottonseed oil and cottonseed deep processing solutions for the entire supply chain - cottonseed oil refining, cottonseed oil hydrogenation, refined cotton cellulose, cottonseed protein and more.

Cottonseed Oil Mill Plant

- Usage: cottonseed oil

- Production capacity: 10T-3000T/D

- Voltage: 220V/380V/440V

- Weight: 1050 KG

- Dimension (L*W*H): 1610x615x1260mm

- Power (W): 10 -50kw

Cottonseed oil is extracted from the seeds of cotton plants. Refined cotton seed oil is edible. India, China, Pakistan, USA and Brazil are among the top producers of cotton seed oil in the world. Let us now know about the various aspects of cottonseed oil plant - it's manufacturing process, world market status and other features.

The equipment cost of 5ton per day small cotton seed oil manufacturing workshop is about $8000. The larger the output, the greater the difference of investment cost between different project design. Start Small Cottonseed Oil Milling Business. Here is the main equipment for small scale cotton seed oil mill plant:

How to Operate Cottonseed Oil Refining Machine? - Term Paper

- Type: cooking oil refining machine

- Appearance: Uniaxial

- Customized: Customized

- Press Materials: Sunflower, Soybean, Coconut, Peanut, Mustard

- Delivery time: 7~30 days once order confirmed

- Port: Shanghai, Guangzhou, Chongqing, etc.

Cottonseed oil refining machine operational guidelines: 1 will borrow vacuum suction or oil transfer pump decoloring oil into the deodorizing cans, reservoir depth of 1.0 1.4 m is advisable. Intermittent deodorization oil accounts for 60-70% of capacity. Note: the height of the housing should be 2 to 3 times the diameter of the.

Human body consumption of cottonseed oil is up to 98%. Cottonseed Oil Needs Refining. It is said that refining process can reduce toxicity. Cottonseed oil is one of main cooking oil. But crude cottonseed oil contains gossypol (approximate 1%), colloid and waxiness (content varies with shell content), and the quality is poor.

HUATAI Provides Turnkey Oil Mill Plant, Oil Pressing Machine

- Raw Material: cottonseed oil

- Production capacity: 10T-5000TPD

- Power (W ): 10kw-50kw

- Voltage: 220V/380V/440V

- Dimension (L*W*H): 2500mm*2000mm*3000mm

- Weight: 2T-20T

Cotton Seed Oil Refinery Plant. Oil Refining is the progress of removing impurities such as phospholipids, FFA, pigment, and off-flavor in cruel oil before edible application. An oil refining machine is used for producing the first or second-grade edible oil. We are able to supply the professional oil refining plant and related oil refining

The cottonseed meal we produce contains low gossypol content and light color, and the protein content can be adjusted according to customer needs. Cottonseed oil refining can be divided into batch refining, semi-continuous refining and continuous refining according to the capacity of the production line.