automatic palm kernel oil expeller machine price in Cameroon

- Type: palm oil processing machine

- Usage/Application: palm fruit, palm kernel

- Production capacity: 3 - 6 kg

- Voltage: 220V/240V

- Warranty: 2 years

- Weight: 7400 kg

- Dimension (L*W*H): 90*40*68 cm

- Country: cameroon

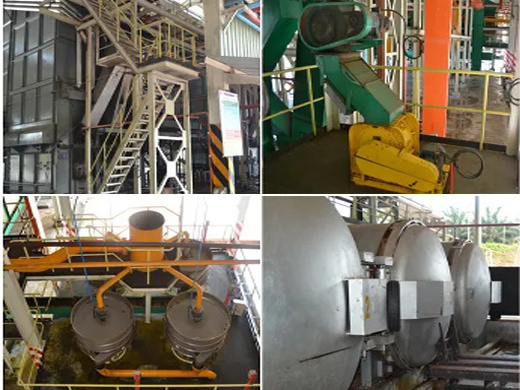

We manufacture and supply Palm Oil Processing Machine in Cameroon at a factory competitive price with features: Palm Oil Processing Machine, 1.Rotocel extractor&loop extractor;, 2.High. Muar Ban Lee Group is a world-leading palm kernel expeller manufacturer specializing in palm oil machinery and oil seed crushing machinery. We provide "One Stop

Palm oil production line | Palm oil mill - Hongde Oil Machinery

- Type: palm oil refinery machine

- Production capacity: 45~70 kg/h

- Voltage: adjustable

- Weight: 1100kg

- Dimension (L*W*H): 1050*950*1650(mm)

- Power ( W): 2 KW

Hongde Oil Machinery is a leading company in the field of palm oil pressing and palm kernel oil processing and equipment, we can provide completely set of 5-120tph palm oil production line. Our company offers a range of products and services for the palm oil extraction, palm kernel oil extraction, crude palm oil refining and complete palm oil

The pulp part is processed by palm oil pressing machine to extract crude palm oil; the kernel part is crushed and extracted by a special palm kernel press. The crude palm oil is refined by palm oil refining machine to remove impurities, sourness and color, and it can become clear edible oil in the supermarket; if the customer needs to produce

Highly Efficient Palm Kernel Oil (PKO) Processing Machines at

- Usage: palm oil

- Production capacity: 100% chia seed oil expeller pressure screw

- Voltage: 220V/380V/440V

- Weight: 50tons

- Dimension (L*W*H): 48m*12M*15M(50tons)

- Power (W): 5.5-22KW

Detailed palm kernel oil extraction process by mechanical pressing method is as follow. Palm Kernel Oil (PKO) Processing Flow Chart. Palm Kernel and Shell Separation - Palm Nut Cracker; Palm kernel and palm shell are obtained through the separation between kernel and shell. Normally, the shell can be used as fuel in the boiler system.

Dingsheng Machine provides palm oil refining solutions, batch refining (1-30 tons per day), continuous refining process, semi-continuous refining process, small palm oil refining production line equipment for degumming, deacidification, decolorization, deodorization and fractionation.

Palm Oil Mill Plant Production Line - Hongde OIL MACHINE

- Type: cooking oil refining machine

- Production capacity: 10--1000TPD

- Power (W): Capacity

- Voltage: 220V, 380V

- Dimension (L*W*H): 1200*400*900mm3

- Weight: According to its capacity

The palm oil degumming and deacidification process uses a washing method to separate soap residual from mixing oil, providing preparation for the next step palm oil refinery machine. Bleaching Process. The palm oil bleaching process is mainly used to remove oil pigment, residual soap, and metal ions during palm oil refining machine.

Palm Kernel and Shell Separation: The kernel is sent to palm kernel oil extraction machine, while palm kernel shells are sent to boiler to be used as fuel. Separating the shells from the kernel can not only greatly improve the oil yield and production efficiency, but also help reduce the wear of oil extraction equipment.

Palm Oil Refining Machine

- Raw Material: palm

- Production capacity: 50

- Dimension (L*W*H): 830*750*1240

- Voltage: 380V

- Weight : 5100kg

- Main components: Motor

Palm Oil Refining Machine. Palm Oil Refinery is the main oil machinery and equipment to ensure the quality, grade and edible safety of oil in the palm oil processing process. The palm oil refining machine produced by Henan Hongde Cereals and Oils Machinery Co., Ltd. can flexibly adapt to different production needs with advanced technology

The purpose is to process the fibrous palm kernel through a series of pretreatment, then press it, and finally pass through the refining equipment to obtain edible refined palm kernel oil. The following mainly introduces the three kinds of pressing line process, refining production lines and the equipment used in them.