Peanut Oil Processing Technology - ScienceDirect

- Type: peanut oil extraction machine

- Usage/Application: peanut, groundnut

- Production capacity: 100%

- Voltage: 220V/380V

- Weight: 1200kg

- Dimension (L*W*H): 450* 230*350mm

- Power (W ): 7.5 kw

- Country: kenya

After being mixed at a certain ratio, the crude oil is put into the sedimentation tank for sedimentation. After sedimentation, the crude oil is pumped into the frame filter for filtration, and the filtered product oil will be filled and packaged by a filling machine to form superfine fragrant peanut oil products (Fig. 3.9).

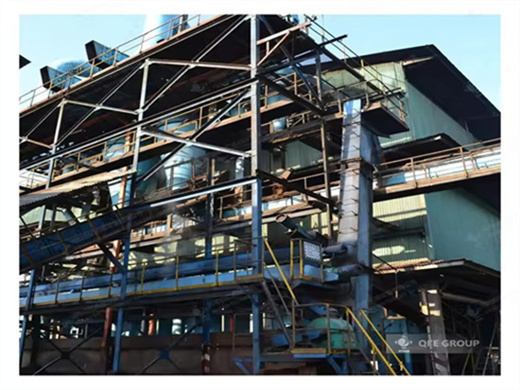

peanuts oil extract machine peanuts oil line in kenya

- Type: peanut oil processing machine

- Production capacity: 1-2000TPD

- Voltage: 220V/380V/440V

- Weight: 30 tons

- Dimension (L*W) *H): 48m*12M*15M(30TPD)

- Power (W): 18.5 KW/T

What technology is used in peanut oil production? It starts by explaining the pretreatment technology and peanut pressing technology of high temperature and cold pressing peanut oil. It then discusses the peanut oil extraction technology, which includes leaching and separation technology. At the end of the chapter, it discusses the peanut oil production line and the relevant […]

This review elucidates the methods used for extracting peanut oil, including mechanical and chemical processes that have been combined with biological or physical pre-treatment techniques.

What is the basic principle of peanut oil solvent extraction?

- Usage: peanut oil

- Production capacity: 150-300kg/h

- Voltage: 220v/380v/Customer request

- Main components: Motor

- Weight: 1100 KG

- Dimension (L*W*H): 1900*1400 *1700mm

Peanut oil solvent extraction system. The mixed oil and wet meal were obtained by desolventizing peanut oil in peanut meal with n-hexane organic solvent in the leaching system. Wet meal desolventizing system. This system use desolventizing toasting drying and cooling tower (D.T.D.C) to desolventizing, toasting, dry and cool the mixed oil in the

For this reason, the main by-product of peanut oil production (peanut cake) generated using traditional methods which contains >50% protein is mainly used as a feedstuff or fertilizer. In the past few decades, aqueous extraction processing (AEP), has been developed to separate oils and proteins from oil-containing starting materials ( Fig. 1

Peanut Oil Production Line -Hongde grain and oil machinery co., LTD

- Type: cooking oil extraction machine

- Voltage: 380 V/50 HZ

- Power (W): 15 KW

- Raw material: rice bran, Almonds

- Weight: 1200kg

- Dimension (length x width x height): 1700*1100*1600mm

Then the settled oil residue is discharged regularly and separated from oil. Cooling and coarse filtration process: the pressed crude oil after removing the dregs rigorously is pumped into the cooling oil tank. Stir the oil slowly to cool it to a certain temperature, and then pump the cooled oil into the oil filter for coarse filteration.

processing most widely used is the peanut oil. The peanut cake or meal obtained after oil extraction which can be full fatted, partially defatted or defatted is later used as flour, isolates and concentrates [6]. Oil extraction from the peanut kernel is a well-established industrial since the early 1950s. They have thus supported in

Mechanical Methods of Oil Extraction from Peanuts

- Raw Material: peanut

- Voltage: 220 V

- Press materials: Sunflower, Soybean, Coconut, Peanut and mustard press

- Appearance: Shaft

- Series: Fourth

- Customized: Non-customized

To commercially extract cold-pressed peanut oil, a twin-screw press is used, and the pressing is performed at specific temperatures that do not exceed 60 °C. The oil yield was not evaluated in this study, but the researchers were very interested in utilizing the by-product of this extraction (i.e., the meal), knowing that 70 kg of PDPM was

techniques for oil extraction from peanuts are grouped into three main sections: extrusion and screw pressing, cold pressing, and hydraulic pressing. oil extraction mechanical methods defatting peanuts defatted peanuts peanut proteins texturization MEPSI 1. Introduction Peanut, or