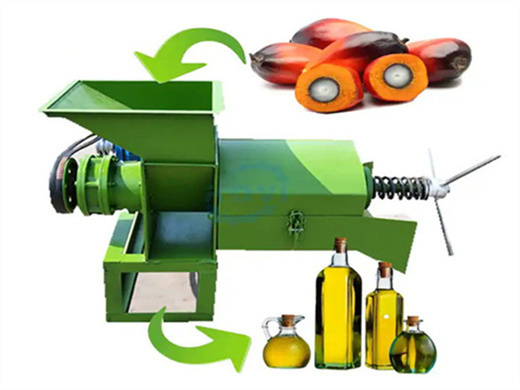

Palm Oil Processing Machine. Palm Fruit Oil Extraction

- Type: palm oil press machine

- Usage/Application: palm fruit, palm kernel

- Production capacity: 18-21 TPD

- Voltage: 60 HP

- Main components warranty: 5 years

- Weight: 10000 KG

- Dimension (L*W*H): 3505-1820-1981

- Country: mozambique

Cost-Effective: The Palm Oil Press Machine’s low energy consumption and minimal maintenance costs make it a highly cost-effective solution for palm oil production. Durable and Long-Lasting : The heavy-duty construction and use of high-quality materials guarantee durability and long-term trouble-free operation.

Oil Press Plant Hcrank Oil Press in mozambique

- Type: palm oil processing machine

- Production capacity: 100% sunflower seed oil refinery equipment

- Voltage: 220V/380V/440V

- Weight: Depends on its capacity

- Dimension (L*W) *H): Depends on its capacity

- Power (W): 10-50kw

Palm oil pressing line refers to the palm oil production process to extract crude palm oil out from fresh palm fruit bunches(FFB). The standard palm oil production process mainly includes seven steps.

Hello, sir. We can supply compete palm kernel oil production plant from 1tpd to 400 tpd. A 10 tons per day palm kernel oil production line will cost about is $ 60,000 around. The required equipment is palm kernel crushing and separating machine, palm kernel oil extraction machine, oil filter machine, palm kernel oil refining machine, etc

Understanding Palm Oil Processing Plant Cost

- Usage: palm oil

- Certification: ISO, BV, CE, CE, ISO9001, BV, etc...

- keyword: cooking oil production

- Power consumption: ≤ 15KWh/T

- Steam consumption: ≤ 280KG/T (0.8MPa)

- Residual oil in flour: ≤ 1%

Single Palm Oil Press Machine Price: Referring to single screw pressing type of palm oil processing machine, a small oil press is generally priced at around $2,000.00 - $3,000.00, while for complex palm oil press machine for industiral oil mill plant, with a main motor of 18.5 kW and have a packing dimension of 255 x 170 x 205 cm, the price is

Supply turnkey palm oil pressing plant and all kinds of quality palm oil machines including palm oil press, palm oil expeller and filter with competitive price. Send an inquiry now and tell us your budget, situation and other requirements. Then we can guide you starting palm oil pressing and refinery business step by step.

Market Palm Kernel Coconut Oil Press Machine in mozambique

- Type: cooking oil extraction machine

- madel: rotocel extraction

- cooking oil solvent extraction machine: carbon steel and stainless steel

- function: solvent extraction

- Crude oil moisture and volatile matter: ≤ 0.30%

- Solvent consumption: ≤ 3Kg/T (6 #solvent oil)

Palm oil processing plants do a variety of complex processes in order to convert raw palm fruits into edible oil. For instance, the palm oil press machine, widely used in small to medium sized palm oil pressing plants, help the raw material undergo extraction processes using industry standards. These machines have to be compact, stable, durable, easy to install and move, and economical.

Get customized palm oil mill business plan to start a household or commercial palm oil processing industry with estimated cost and specific machines from Our Machinery! Toggle navigation info@bestoilmillplant.com 0086 372 5965148

Palm Oil Processing Production Line

- Raw Material: palm

- Production capacity:1000kg/day

- Dimension (L*W*H):2680*680*1490mm

- Voltage:380v/customized

- Weight: 250 KG

- Main components: motor, pressure vessel, motor

For small-scale palm processing farmers, Dingsheng Machine has designed single-screw and double-screw palm fruit oil press, which can process 1ton, 5 tons, 10 tons and 15 tons of palm fruit per hour. Reliable palm oil press machine with simple operation, gaining a good reputation in Africa and South America.

For large capacity palm oil refining machine, the popular capacity is 100tpd, 200tpd, 600tpd, 800tpd, 1000tpd and so on. 100tpd palm oil refining machine be continuous palm oil refining machine. 100tpd palm oil refining machine has features of advanced technology, automatic control system, high equipment configuration and so on.