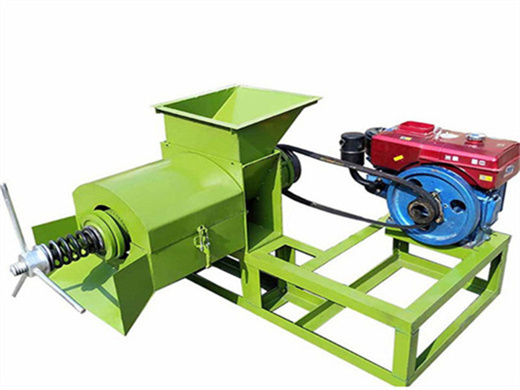

Palm Kernel Oil Manufacturing Machine

- Type: palm oil extraction equipment

- Usage/Application: palm fruit, palm kernel

- Production capacity: 50-1000 kg/h

- Voltage: 380 V

- Main components: motor, pressure vessel, pump, PLC, others, gears, bearings, motor, gearbox

- Weight: 1200 KG

- Dimension (L*W*H): 1700*1100* 1600 mm

- Country: kenya

PALM KERNEL OIL PROCESSING PROCESS. Mechanical extraction processes are suitable for both small, medium and large capacity operations. The basic steps are : Palm Nut Cracking & Shell Separation Unit; Palm kernel Mechanical Pressing Unit; Palm Nut Cracking & Shell Separation Unit. Palm Nut is one of the byproduct of Palm Oil Extraction Plants.

Oil Palm by Product: How to Compute Its Cost of Production

- Type: palm oil processing machine

- Voltage: 220V/380V

- Power (W): according to cooking oil refining machinery specification

- Certification: ISO9001

- Weight: according to the specification of cooking oil refining machinery

- Dimension (L*W*H) : according to the specification of cooking oil refining machinery

The main literature of this study can be used is “cost accounting” and the other are palm oil text book in order to know the characteristic of oil palm and its products. Nowadays, oil palm industry (Syamsul Bahri, 2016) is as the interesting business, especially, among the plantation industries, because of its high average return rate.

6. Energy Consumption Cost. Palm oil production is an energy-intensive process, particularly during the palm fruit sterilization and palm oil extraction stages. The cost of electricity, water and other utility consumption may be factored into the total investment.

Palm Oil Production Process: A Step-by-Step Guide

- Usage: palm oil

- Production capacity: 0.5-20t/d

- Voltage: 380V or customized

- Main components: motor, pressure vessel, pump, PLC, gear, bearing, motor, gearbox

- Weight: 6t

- Dimension (L*W*H): 6*1. 2*2.3 m

The Palm Oil Production Column will introduce the details of each process, providing you with the guidance and support you need for your palm oil business. Unveiling Palm Oil Production Process Steps Refining Process-Starting a Palm Oil Refining Plant Cost

Single Palm Oil Press Machine Price: Referring to single screw pressing type of palm oil processing machine, a small oil press is generally priced at around $2,000.00 - $3,000.00, while for complex palm oil press machine for industiral oil mill plant, with a main motor of 18.5 kW and have a packing dimension of 255 x 170 x 205 cm, the price is

Palm Oil Extraction Process, Methods, Steps | Agri Farming

- Type: cooking oil extraction machine

- Production capacity: 20-2000TPD

- Voltage: 380V

- Weight: standard

- Dimension (L*W*H): standard

- Power (W): Standard

Palm oil extraction process: Palm oil is extracted during a carefully monitored series of phases that seeks to make sure that the end product is highly appealing. Palm oil extracting plant generally begins with the harvesting of the fruit. This is the process of palm oil physical extracting (screw pressing) and field factors that determine

The palm oil milling process involves several stations, including sterilization, threshing, digesting, pressing, and clarification. The palm oil milling equipment cost is between 1350USD and 397,000 USD depending on the processing capacity and specific pa

Small Palm Oil Milling Factory to Start Edible Oil Business

- Raw Material: palm

- Production capacity: 5TPD-100TPD

- Dimension (L*W*H): According to capacity

- Voltage: According to capacity

- Weight : KG

- Warranty: 1 year, 12 months

Complete palm oil production process in large scale or industrial scale palm oil factory begins with harvesting the fresh fruit bunches (FFB) of oil palms. After the fruit is harvested, it is processed in a palm oil mill , where the FFB is sterilized, digested, and pressed to extract the palm oil.

the kenya Basin’s palm oil sector In both the kenya Basin and Southeast Asia, smallholders are an engine of growth in the palm oil sector. In the kenya Basin, however, oil palm production and supply chains differ from Southeast Asia in two key ways: Non-industrial actors process the oil independent of companies and consumers are mostly local.