Cottonseed Oil Mill Plant

- Type: cottonseed oil extraction mill

- Usage/Application: cottonseed

- Purpose: Small cooking oil making machine

- Description: Semi-continuous

- smell: no unpleasant smell

- color: fresh and bright

- Material: Stainless steel

- Country: uganda

Cottonseed Oil Pressing / Expelling (by using Mechanical Screw type Oil Press); Cottonseeds can be pre-pressed before they get sent directly to the refinery plant. To handle 20 tons of cottonseed per day, the solvent extraction method is used with cottonseed oil prepress to take parts of the oil.

Cotton Seed Oil Expeller - Multi Seeds Oil Machine

- Type: cottonseed oil processing machine

- Production capacity: 5TPD-100TPD

- Voltage: 220V/380V/440V

- Warranty: 1 year, 12 months

- Weight: 800 KG

- Dimension (L*W*H): 1200*1100*1000mm

Cottonseed oil extraction involves a series of oil manufacturing process and professional oil processing machinery. Whatever your cottonseed oil mill plant is small or large, the basic manufacturing process is needed to produce high quality cottonseed oil.

The traditional cottonseed oil extraction process involves pressing or extraction. The common cottonseed oil processing flow: cottonseed - cleaning - shelling - shell kernel separation - embryo rolling - high moisture steaming - pre-pressing - solvent extraction. Cottonseed oil contains a large amount of essential fatty acids, among which

Steps of Cottonseed Oil Processing Process - Oil Mill Machinery

- Usage: cottonseed oil

- Production capacity: 98%-100%

- Voltage: 380

- Weight: 780kg

- Dimension (L*W*H): 2200*1600*2150

- Power (W): 5.5 KW~15KW

The residue & solid powder is separated through automatic oil-dreg separator. After separating, we can get two products, one is crude oil with impurity of 1% which will be refined or filtered further by Filtered Press; the other is residue with oil which is conveyed back into Screw Press to repress to get rest oil. Cottonseed Oil & Cottonseed

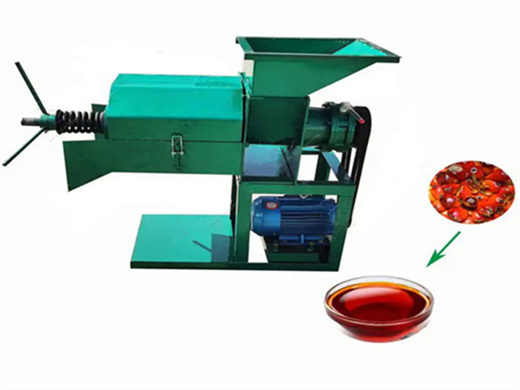

Cotton Seed Oil Processing Machine (1~20T/D) Different from traditional screw oil press, our cotton seed oil machine is available with heating device. Therefore, you have the choice to save preheating time of the machine itself. More importantly, it can greatly improve the oil output as well as quality of crude cotton seed oil.

Cottonseed oil mill plant manufacturers| Cotton Seed Oil

- Type: cooking oil extraction machine

- Production capacity: 350-7000 KG/H

- Power (W): depends on the mode of the cooking oil grinding machine

- Voltage: 220V/380V

- Dimension (L*W*H): 900 mm * 850 mm * 1550 mm

- Weight : depends on the mode of the cooking oil grinding machine

Our cottonseed oil extraction plant uses a well-structured process to extract premium oil from cotton seeds. With precise cleaning, dehulling, and solvent extraction, we ensure maximum yield and purity for various industrial and edible applications.

Read more about cottonseed oil solvent extraction method >>. Set Up A Cottonseed Oil Mill Plant. This small small oil mill is not only suitable for cotton seeds, it is also ideal choice for extracting oil from many other oil seeds and nuts, such as mustard seed, peanut, flaxseed, linseed, poppyseed, groundnuts, sesame seed, canola seed, sunflower seed, soybeans, etc.

Cottonseed Oil Processing Machines Set up Complete Oil Mill Plant

- Raw Material: cottonseed oil

- Production capacity: 10 tons to 500 tons per day

- Dimension (L*W*H): According to production capacity

- Voltage: 380 V

- Weight: 10000 KG

- Main components: motor, pressure vessel, pump, bearing, motor

The complete cotton processing plant has a series of process, including delintering, dehusking, oil pressing, solvent extraction for oil, oil refining and more. Now, it has been a popular for many investors or oil millers to start or expand their edible oil manufacturing business by setting up cotton seed oil processing plant .

Cotton seed oil expeller are readily available with various companies assembling machines that are well versed for small oil mill of cotton. The expeller come in different size and shapes even for the small-scale producers with limited spaces. Small oil mill factory encourages self-employment as more jobs are generated.