Steps of Cottonseed Oil Processing Process - Oil Mill Machinery

- Type: cottonseed oil extraction mill

- Usage/Application: cottonseed

- Production capacity: 98%

- Voltage: 220 V/380 V, 440 V

- Weight: according to the corn oil mill capacity

- Dimension (L*W*H)): depends on the capacity of corn oil mill

- Power (W): as capacity of corn oil mill

- Country: botswana

In this section we use Magnetic Separator, Vibrating Sieve, de-stoner, decorticator (Cotton seeds used hammering decorticator). Through cleaning the impurity, you can reduce the lost of oil & improve the oil yield and the environment of production plant. The material has been produced after pretreatment contains the impurities ≤ 0.1%.

Cottonseed Oil Extraction Plant

- Type: cottonseed oil processing machine

- Production capacity: 5-500 TPD

- Voltage: 440 V

- After-sales service provided: Engineers available to service machinery abroad.

- Certification: ISO,CE

- Weight: 500 TONS

50T/D Edible Oil Production Plant; 30T/D Edible Oil Production Plant; 10-20T/D Edible Oil Production Line; 1-50T/D Edible Oil Production Line; Oil Refinery Plant. Large Continuous Edible Oil Refinery Plant 20-5000TPD; Batch-type Edible Oil Refining Equipment 1TPD to 20TPD; 10T/D Edible Oil Refinery Plant; 1-5T/D Edible Oil Refinery Plant

Experience improved performance with our advanced cottonSeed oil solutions.. Boost your cotton oil production with our premium cotton seed oil extraction machines. As leading Cotton Seed Oil Extraction Machine manufacturers, we prioritize precision, efficiency, and high quality in our processing equipment.

cotton seed oil mill project report

- Usage: cottonseed oil

- Main components: motor

- Arc current: standard

- Rated Duty Cycle: Standard

- Pilot arc current: standard

- Pulse frequency: standard

Cotton seed oil contains 60% ~ 90% of unsaturated fatty acids (linoleic acid and oleic acid), which has the functions lowering cholesterol, preventing atherosclerosis, etc. It is an also important kind of edible vegetable oil. (Related post: Vegetable Oil Production Business Plan >>) Start Business in Cotton Oil Mill

Cottonseed oil is extracted from the seeds of cotton plants. Refined cotton seed oil is edible. India, China, Pakistan, USA and Brazil are among the top producers of cotton seed oil in the world. Let us now know about the various aspects of cottonseed oil plant - it's manufacturing process, world market status and other features.

Complete Cotton Seed Oil Processing Plant

- Type: cooking oil extraction machine

- Production capacity: 1200-10000L/H

- Dimension (L*W*H): 15X12X15m

- Voltage: 380V

- Weight : 1280Kg

- Main components: motor, pressure vessel, pump, Motor

But, you may have a lot of questions about how to establish your own oil mill plant to process cotton seeds, among which cottonseed oil production process, cottonseed oil mill machinery and price, and complete cotton seed oil processing plant setup cost are the most important and relatively complicated. Fortunately, you are at the right place

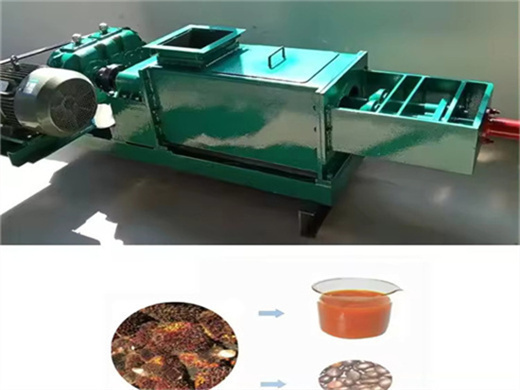

A step-by-step guide to Cotton Seed Oil Manufacturing Project Report, and Business Plan Applications of Cotton Seed Oil. Cottonseed oil is obtained by extracting it using seeds of various cotton plants. These plants are majorly grown for cotton fiber, animal feed, and oil. They are similar to sunflower seeds in structure.

Complete Cottonseed Oil Production Lines. Cottonseed Oil

- Raw Material: cottonseed oil

- Production capacity: 100% oil press machine

- Power (W): 5.5 ~ 18.5 KW

- Voltage: 220V/380V/440V

- Dimension (L*W* H): 1950*1300*1900, according to capacity

- Weight: 950KG

For cottonseed oil production lines with a capacity of over 20 TPD, a solvent extraction method is adopted to work together with cottonseed oil pre-press to extract the rest cottonseed oil. Solvent Extraction : Cottonseed flakes or press cakes undergo solvent extraction to recover residual oil.

Machinery & Equipment required to Setup a Cottonseed Oil Mill Plant. The requirement of machinery and equipment for Cottonseed Oil Mill usually depends on the various aspects such as processing raw materials, required pressing capacity, production cost budget and other detailed information.