Cottonseed oil mill plant manufacturers

- Type: cottonseed oil machine

- Usage/Application: cottonseed

- Production capacity: 300-8000 KG/H

- Voltage: 220v/380v/Customer request

- Main components: Motor

- Weight: 300 KG

- Dimension (L*W*H): 1020* 720*798mm

- Country: lagos

Our oil extraction machines are engineered with the latest innovations to ensure your cottonseed oil production meets the industry standards and you gain a competitive edge. Global Reach With a robust global presence, we serve clients worldwide with timely delivery, comprehensive support, and service excellence, regardless of your location.

Small Scale Oil Mill of Cotton Seed

- Type: cottonseed oil processing machine

- Automatic Filter Press: Automatic Design Membrane Filter Press

- Filter Capacity cooking oil press: According to the capacity of cooking oil plant

- Oil Membrane Filter Press: Industrial Oil Press Filter Machine

- Filter plate squeezer Cooking Oil Membrane Filter: High Pressure Oil Squeezer Design

- Filter grain oil press: for cooking oil industry operation

My name is Dionisis Pontikis and I am the General Manager of a grain processing company. I am starting up a new business of extracting oil from cottonseed in Greece. I would like to send me an offer of the press oil machine type: ZX24-3 & 204-3 oil mill machine. I would also like to inform me what other equipment do I need and if you sell this

In case of trouble is occurred in some area of the single tank, each single tank can stop for checking and repairing without stopping the whole production line. (Read more: mini oil mill project cost) Photos Display: Successful Cotton Seed Oil Processing Project at Our Machinery. Cotton Oil Making Machinery Manufactrued with Different Materials

Small Scale Oil Pressing Line - Oil Mill Machinery

- Usage: cottonseed oil

- Production capacity: 2-4 kg/h

- Voltage: 110 V/220 v

- Nominal voltage: 110 V/220 v

- Oil Product Function: Oil press

- Dimension (length x width x height): 42 x 16 x 30 cm Weight: 11 kg Main components: Motor, Pressure vessel

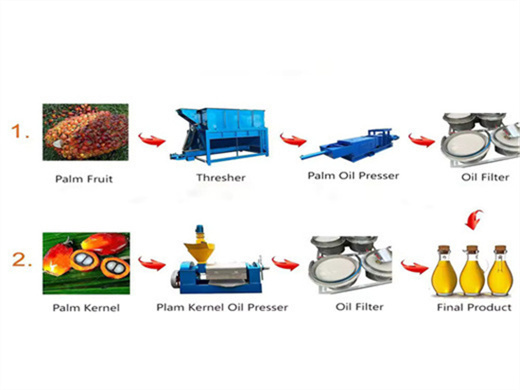

The small scale oil pressing line requires little initial investment and a minimal workspace, but performs all functions necessary for edible oil production. Our small scale oil processing line can prepare many kinds of oilseeds including peanut kernels, rape seeds, cotton seeds, sunflower seeds, corn seeds, palm kernels and sesame seeds. The

As the last step in the cotton processing plant, baling is closely associated with the normal operation of the whole production line. Choosing a good baling machine will make the whole production line perfect. With advanced design, our MDY-400 hydraulic cotton baling machine can automatically complete multiple processes, such as cotton

Projects-Zhengzhou Dingsheng Machine Manufacturing Co., Ltd

- Type: cooking oil extraction machine

- Production capacity: 300TPD

- Voltage: 380V, 380V

- Weight: 10T

- Dimension (L*W*H): 2.5*3.5*3.5 m

- Power (W): 100kw

our machines are sold all over the world and exported to lagos, Italy, Uzbekistan, Bulgaria, Malaysia, Russia, Kazakhstan and other 80 countries , we enjoy a high reputation in domestic and foreign customers.

To handle 20 tons of cottonseed per day, the solvent extraction method is used with cottonseed oil prepress to take parts of the oil. The machine used for the job has a large capacity and its cake leaves less residual, which makes it easy for the solvent to penetrate. Oil Filtering; Residual oil can be collected with the use of an oil residue

Cottonseed Oil Manufacturing Process and Machinery

- Raw Material: cottonseed oil

- Production capacity: 98%-100%

- Power (W): 22kw

- Voltage: 380V/50HZ

- Dimension (L *W*H): 48m*12M*15M(30TPD)

- Weight: 10 tons

One of the widely used machine used in cottonseed oil manufacturing plant is screw cottonseed oil machine, a type of cottonseed oil machinery. It’s very simple in nature and can be used to extract oil from various seed plants. The screw cottonseed oil press is a mini cottonseed oil machine that can be used for small-scale extraction oil plants.

Mini Oil Mill means a small capacity oil processing plant or even a small assembly line to meet the local market. Generally, the mini oil mill combines a series of machines together to increase the production, to achieve high oil yield and to improve the job security of workers. The whole line is easy to install, operate and commission.