Cottonseed Oil Production Line

- Type: cottonseed oil machine

- Usage/Application: cottonseed

- Voltage: 2200W

- Dimension (L*W*H): 800*620*1170 mm

- Oil type: Cooking oil

- Components main: Engine

- Weight: 136 KG

- Country: nairobi

Cottonseed oil degumming is generally used in water dehydration process. Adding a certain amount of phosphoric acid solution to condense the colloid impurities, and then sink the colloid impurities and separate the oil. Cottonseed oil deacidification process has two kinds: chemical and physical. The chemical deacidification process is to add

Cottonseed Oil Production Line - Industrial Development

- Type: cottonseed oil processing machine

- Production capacity: 50-1000 kg/h

- Voltage: 380V/440V or required

- Main components: Others

- Weight: 1250 KG, 1250kg

- Dimension (L*W*H): 2000* 1300*1850MM, 2000*1300*1850MM

The deodorization process can not only remove the odors from crude cottonseed oil, but also improve smoke point, flavor, steadily and quality of final oil. At last, cottonseed oil refining has a special process — cottonseed oil fractionation process. It is to seperate the solids and liquids in cottonseed at a specific temperature.

Brief Overview of Cottonseed Oil Production Line. 1. The cottonseed oil production process is advanced, with full consideration of low cost, energy saving, environmental protection, and thermal energy recovery and reuse. 2. The process can achieve fully automated control. 3.

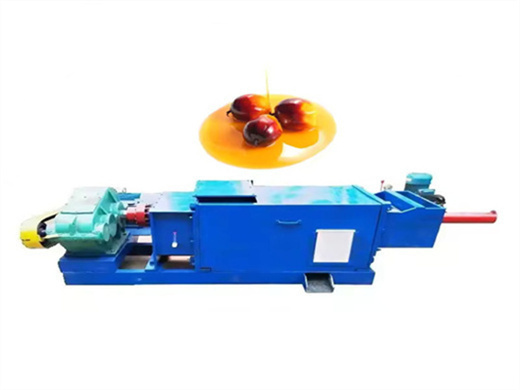

Edible Oil Dewaxing Machine - Henan Hongde Cereals And Oils

- Usage: cottonseed oil

- Voltage: 380 V

- Appearance: Horizontal

- Customized: Non-customized

- Press series: Fourth

- Press materials: Sunflower, All seeds

Precautions for Edible Oil Dewaxing Machine. Before cooling, oil should be heated firstly to make the wax that has been precipitated at room temperature(wax precipitates when room temperature is lower than the crystallization temperature.)completely dissolved in oil liquid, which can enhance the following dewaxing effect.

CHEMSTA vegetable oil&fats refining production line is used to refine various oils, including soybean oil, rapeseed oil, cottonseed oil, peanut oil, sunflower seed oil, corn germ oil, and rice bran oil. This production line features a capacity of 30-1,000 tons of crude oil per day, and is able to eliminate plasticizer (DEHP) pollution

Cottonseed Oil Production Line - QI'E Group

- Type: cooking oil extraction machine

- Production capacity: 60-800 kg/h

- Dimension (length x width x height): 2000*1100* 1950 mm3

- Voltage: 220 V/380 V

- Weight: 450 KG

- Main components: Motor, Pressure vessel, Pump, PLC, Gear, Bearing, Motor, Gearbox

Pre-treatment and Pre-press Cottenseed → Metering→Winnowing → Husking→Flaking→cooking→Pressing→Cake Shelling The shell of cottonseed is very solid, removing the shell is the first step before extracting oil protein. Kernel husk separator It is mixture after shelling of cotten seed.The mixture includes full oil seed without any crushing,seed shelled and husk,all the mixture must

It is almost necessary to dewax the following products (such as corn oil, rice bran oil, sunflower oil, cottonseed oil, etc.). Oil fractionation is done by using the differences in glycerol’s melting point and solubility contained in various oils to divide the oil into solid fats and liquid oils.

Cottonseed Oil Processing Plant | Extraction Flow

- Raw Material: cottonseed oil

- Production capacity: 20 tpd

- Dimension (L*W*H): 1200 (L) * 1200 (W) * 2100

- Voltage: 380 V

- Weight: about 35 tons

- Warranty: 2 years

Cottonseed oil contains a large amount of essential fatty acids, among which linoleic acid has the highest content, which can reach 44.0-55.0%. In addition, cottonseed oil also contains 21.6%-24.8% palmitic acid, 1.9-2.4% stearic acid, 18%-30.7% oleic acid, and 0-0.1% arachidic acid. Cottonseed oil can be used for cooking and consumption.

We are professional manufacturer of cottonseed oil refining line,we can supply 1-20T/D batch cottonseed oil refining line,30-50T/D semi continuous cottonseed oil refining line and 50-600T/D continuous cottonseed oil refining line .Now, we mainly introduces the batch edible oil refining line.