Cottonseed Oil Mill Plant

- Type: cottonseed oil refinery plant

- Usage/Application: cottonseed

- Production capacity: 10-100TPH

- Voltage: 220V/380V/440V

- Weight: According to the cooking oil processing capacity

- Dimension (L*W*H): 1200*400*900mm3

- Power (W): 10 -50kw

- Country: lesotho

Cottonseed Oil Pressing / Expelling (by using Mechanical Screw type Oil Press); Cottonseeds can be pre-pressed before they get sent directly to the refinery plant. To handle 20 tons of cottonseed per day, the solvent extraction method is used with cottonseed oil prepress to take parts of the oil.

Our Machinery Turn-key Oil Mill Projects Abroad

- Type: cottonseed oil refinery machine

- purpose: cooking oil machine supplier

- Description: high oil yield

- smell: original cooking oil flavor

- color: fresh and bright

- Material: steel stainless or carbon steel

10 TPD Soybean Oil Refinery Project Completion in Jamaica. 10TPD Peanut Oil Mill Business Plant Built In lesotho. 30tpd Cotton Seeds Oil Refinery Plant in Afghanistan.

Corn Oil Extraction Plant; Cottonseed Oil Extraction Plant; Canola Oil Processing Plant; Coconut Oil Plant; 50T/D Edible Oil Production Plant; 30T/D Edible Oil Production Plant; 10-20T/D Edible Oil Production Line; 1-50T/D Edible Oil Production Line; Oil Refinery Plant. Large Continuous Edible Oil Refinery Plant 20-5000TPD

Oil Mill Plant | Oil Mill Factory | 10-500 TPD

- Usage: cottonseed oil

- Production capacity: 100kg/h~500kg/h

- Voltage: 220V/380V

- Weight: 2000kg

- Dimension (L*W*H): 2050*1350*2000mm

- Power (W): 25kw

Complete quality certification: AGICO has been approved ISO 9001, CE-certified to provide turnkey project services to oil seed processing plants, oil extraction plants, oil refining plants, and related equipment. After-sales service: If you have any problems keeping your plant up and running, we provide service 24/7. We also conduct regular

Undecorticated Cottonseed obtained after Delinting process can be used as a raw material for Cottonseed Oil Extraction Plant. Cottonseed contains 18 – 20 % oil content. After a single stage pressing, about 6 – 7 % residual oil is left in the cottonseed meal which is an excellent source of Cattle Feed.

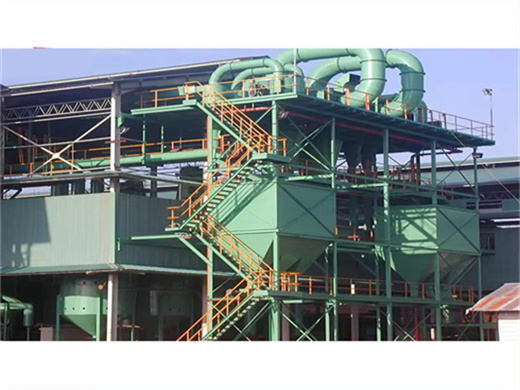

Cotton Seed Processing, Oil Extraction & Refining Plant

- Type: cooking oil refining machine

- Mechanical principle: Pressure filtration

- Capacity: 1t/D

- Performance: Temperature

- Power: 32kw

- Weight: 8 tons

Cottonseed could either be processed by the traditional crude method of crushing seed without Delinting in un-decorticated form or by scientific processing used for Cotton Seed Processing, which involves removal of De-linters, decortication, separation of hull, expelling, solvent extraction and refining of oil. Scientific processing of Cotton

Cottonseed Oil Extraction Process. Cotton Seed Oil Extraction and Refinery Process. When setting up a complete cottonseed oil extraction plant, you must take process design and equipment selection into account. It is important to consider the advantages and disadvantages of the processing technology and equipment.

Mini/Small Solvent Extraction Equipment for Cottonseed Oil

- Raw Material: cottonseed oil

- Production capacity: 5TPD-100TPD

- Dimension (L*W*H): 450*180*280mm

- Voltage: 380V/50HZ, AC220V 50HZ

- Weight: 12 KG

- Warranty: 1 year, 12 months

Why Should Buy Small Solvent Extraction Plant for Cottonseed Oil Production? High ROI: It requires less investment cost and the ROI is high and quick. Easy Operation: The whole tank group for cotton seed oil extraction is easy to operate. Energy-saving: The power consumption of this cotton seed oil production line is small. For example, a 10TPD

Cottonseeds can be once-pressed and then sent to the cottonseed oil refinery plant in small cottonseed oil plants. For cottonseed oil production lines with a capacity of over 20 TPD, a solvent extraction method is adopted to work together with cottonseed oil pre-press to extract the rest cottonseed oil.