Cottonseed oil mill plant manufacturers

- Type: cottonseed oil press

- Usage/Application: cottonseed

- Production capacity: 100% oil refining plant

- Voltage: 220V/380V/440V

- Weight: Depends on its capacity

- Dimension (L*W*H): Depends on its capacity

- Power (W): 10-50kw

- Country: kenya

Cottonseed Oil Extraction Process. Our cottonseed oil extraction plant uses a well-structured process to extract premium oil from cotton seeds. With precise cleaning, dehulling, and solvent extraction, we ensure maximum yield and purity for various industrial and edible applications.

Cottonseed Oil Mill Plant

- Type: cottonseed oil processing machine

- Production capacity: 7-12 kg/h

- Voltage: 220 V, 50 HZ

- Warranty: 1 year, 1 year

- Weight: 12 KG

- Dimension (L*W) *H): 45*180 *28(cm)

Cottonseed Oil Pressing / Expelling (by using Mechanical Screw type Oil Press); Cottonseeds can be pre-pressed before they get sent directly to the refinery plant. To handle 20 tons of cottonseed per day, the solvent extraction method is used with cottonseed oil prepress to take parts of the oil.

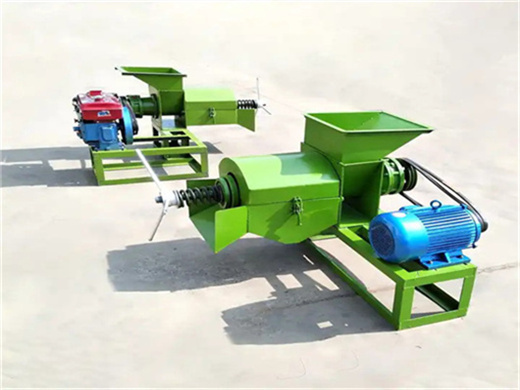

Oil expeller machine is the soul equipment of the pressing process, it can be divided into small oil press and high capacity oil press according to its capacity. The top features of cotton seed oil expeller machine are based on the traditional product but include a variety of enhancements, implemented after-in-depth research on cotton seed oil

Cottonseed Oil Extraction Plant

- Usage: cottonseed oil

- Production capacity: 200kg/h-2000kg/h-100%

- Voltage: 220V/50HZ/Single Phase

- Main components: PLC

- Weight: 27.1KG

- Dimension (L*W*H): 1055*805*345mm

Features of Cottonseed Oil Processing Plant. 1. Cottonseed oil mill plant has high automation degree, continuous operation, saving labor. 2. The pre-pressed cake has low residual oil rate and is easy for solvent penetration. 3. Cottonseed oil extraction plant has multiple oil extractors for selection and advanced mineral oil system. 4.

2. cottonseed oil pre-press→ cottonseed oil extraction→cottonseed oil refinery. Normally for input capacity more than 20 tons per day, it's better to adopt the second Cottonseed Oil Processing Plant processing method with better cost performance. Here we will introduce you the second method. Cottonseed Oil Processing Plant from Pre-Pressing

Steps of Cottonseed Oil Processing Process - Oil Mill Machinery

- Type: cooking oil extraction machine

- Production capacity: 1-500T/D

- Voltage: 380V-415V

- Weight:depends on machine mode of cooking oil

- Dimension (L*W*H):depends on cooking oil machine mode

- Power (W) :depends on cooking oil machine mode

The residue & solid powder is separated through automatic oil-dreg separator. After separating, we can get two products, one is crude oil with impurity of 1% which will be refined or filtered further by Filtered Press; the other is residue with oil which is conveyed back into Screw Press to repress to get rest oil. Cottonseed Oil & Cottonseed

Application of Cottonseed Oil. The cottonseed oil is cholesterol free and extracted from the seeds of various cotton plants. More than 95% of the cottonseed oil is primarily used as cooking oil. Cottonseed oil is light golden color with light mild taste. It is used primarily in the form of mayonnaise or in addition to salads.

Cottonseed Oil Processing Plant | Extraction Flow

- Raw Material: cottonseed oil

- Production capacity: 100% of peanut screw oil press

- Power (W): 15kw

- Voltage: 220V/380V/440V

- Dimension (L*W*H): 1700*1300*1600

- Weight: 0.5-10T

Cottonseed Oil Decolorization. The main purpose of bleaching is to remove pigments from cottonseed oil to improve the color and appearance of the oil. First, we need to heat the degummed (or deacidified) cottonseed oil to 110-120°C. Second, add 0.5-1.5% of an adsorbent such as activated carbon or clay.

Improve the Economic Benefits of your Oil Mill Plant: To extract more oil from the cotton seed cake, soybean seed cake etc., ( After extracting, the oil content in cotton seed meal can reach to 1%. ) Normally, after mechanical oil pressing process , the oil content in oil cake is around 8-13%, through our solvent extracting equipment, you can