Cotton Seed Oil Production Line -QI'E grain and oil machinery

- Type: cottonseed oil machine

- Usage/Application: cottonseed

- Production capacity:4.5TPD

- Voltage: 380V/50HZ

- Warranty: 1 year

- Weight: 587 KG

- Dimension (L*W*H): 1620*580*1165

- Country: cameroon

Section Introduction: Please kindly inform us your required daily capacity, treated quantity, raw material, covering space and related data,so that we can make flow chart production line for you as your requirement. we will stand at your point to suggest low cost and suitable production line for you.

Cottonseed Oil Mill Plant

- Type: cottonseed oil processing machine

- Production capacity: 5-600 kg

- Voltage: 220 V/110 V

- Main components: spare parts

- Weight: 11 KG

- Dimension (L*W*H): 390*149*292 mm

Cottonseed oil is extracted from the seeds of cotton plants. Refined cotton seed oil is edible. India, China, Pakistan, USA and Brazil are among the top producers of cotton seed oil in the world. Let us now know about the various aspects of cottonseed oil plant - it's manufacturing process, world market status and other features.

The complete cotton processing plant includes cottonseeds pretreatment and pressing workshop, cottonseed cake solvent extraction workshop and crude cottonseed oil refinery workshop. There are two main extraction methods of cottonseed oil: one is the pretreatment pressing method, and the other is the solvent extraction method. Different extraction methods use different cotton seed oil processing machine, so this article will introduce the complete cotton seed oil processing plant.

Cottonseed oil mill plant manufacturers| Cotton Seed Oil

- Usage: cottonseed oil

- Production capacity: 80-150 kg/h

- Voltage: 380 V/50 HZ

- Weight: 1200kg

- Dimension (L*W*H): 1700*1100*1600mm

- Power (W): 5.5 kW

Experience improved performance with our advanced cottonSeed oil solutions.. Boost your cotton oil production with our premium cotton seed oil extraction machines. As leading Cotton Seed Oil Extraction Machine manufacturers, we prioritize precision, efficiency, and high quality in our processing equipment.

There are two solution for cottonseed oil production: 1. cottonseed oil press→ cottonseed oil refinery 2. cottonseed oil pre-press→ cottonseed oil extraction→cottonseed oil refinery. Normally for input capacity more than 20 tons per day, it's better to adopt the second Cottonseed Oil Processing Plant processing method with better cost

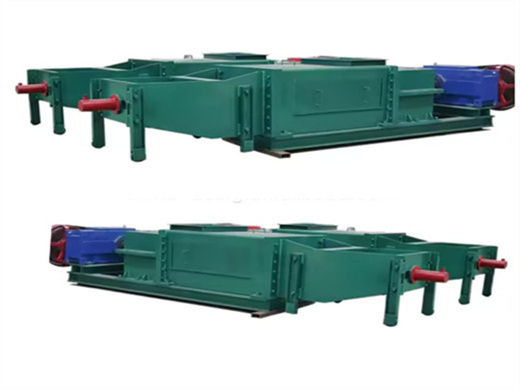

Cottonseed oil production line - Huatai Oil Machinery

- Type: cooking oil extraction machine

- Production capacity: 5TPD-100TPD

- Dimension (L*W*H): 900 *1000*1400mm

- Voltage: 220V/380V

- Weight: 950kg

- Main components: Motor

The pre-pressing and extraction method produces cottonseed oil and crude cottonseed oil refining. The production process of cottonseed oil: stripping → cleaning → magnetic separation → shelling → kernel separation →flaking → expansion, steaming and frying → pre-pressing → extraction → refining → defatting and fractionation

It is only necessary to consider the quality of cottonseed, treatment capacity, market demand for refined oil, investment budget and other factors, and then select the appropriate production process of cottonseed oil production line. Different cottonseed oil production equipment can be selected and configured according to the budget cost in the

Steps of Cottonseed Oil Processing Process - Oil Mill Machinery

- Raw Material: cottonseed oil

- Model: Tqt10

- Operating pressure inside the tower: -0.7bar

- Capacity: 1000t/D

- Operating pressure of clamp cover: 6ppm

- Installation time: 2 months

The residue & solid powder is separated through automatic oil-dreg separator. After separating, we can get two products, one is crude oil with impurity of 1% which will be refined or filtered further by Filtered Press; the other is residue with oil which is conveyed back into Screw Press to repress to get rest oil. Cottonseed Oil & Cottonseed Meal

This small oil press line can also process various oil seeds and nuts, such as coconut, palm kernel, sesame seeds, sunflower seeds, peanuts, soybeans, etc. With less land space needed, low investment, wide application, and labor savings, this small complete plant is the best choice for starting a small oil milling business!