Dewaxing systems for edible oil

- Type: cottonseed oil refinery machine

- Usage/Application: cottonseed

- Production capacity: 100~600 kg/h

- Voltage: 220 V/380 V

- Weight: 950kg

- Dimension (L*W*H): 1950*1300*1900mm

- Power (W): 14 KW

- Country: zimbabwe

Dry dewaxing also has its limitations, such as a maximum wax content of 900 ppm for the feedstock to pass the 24-hour cold test. To achieve effective wax removal, many edible oil producers now combine wet dewaxing and dry dewaxing processes in their refining plants. This combination enables oil producers to pass the 72-hour cold test.

Which oils need dewaxing treatment and what is the process?

- Type: cottonseed oil refinery machine

- Production capacity: floating

- Voltage: Customer's local standard

- Warranty: 2 years

- Weight: KG

- Dimension (L*W*H): depends on model

Oil dewaxing treatment process during edible oil refinery is to remove the wax content in some kinds of crude edible oil, wax is a kind of polymer lipid, high melting point, poor solubility in oil, will affect the taste and transparency of the edible oil, so the edible oil needs dewaxing treatment.

Main Steps of The Edible Oil Dewaxing Process. Conventional dewaxing is the common oil dewaxing method with the working principle of freezing and then mechanically separating oil & wax without any auxiliary means, the separating methods are usually pressure filtration, vacuum filtration, and centrifugal separation.

Edible oil refinery plant and edible oil refining process

- Usage: cottonseed oil

- Condition: New

- Production capacity: 100% cooking oil press machine

- Capacity: 10-1000TPD

- Material: stainless steel Durable carbon and stainless steel

- Weight: 268 KG

The working process of full-continuous edible oil refinery plant: Full-continuous edible oil refining process. Main advantages of full-continuous edible oil refinery plant: 1. Suited for high-capacity lines (low space requirement); 2. Input/output heat recovery; 3. Simple automation and control; 4. Low manning level.

The residue & solid powder is separated through automatic oil-dreg separator. After separating, we can get two products, one is crude oil with impurity of 1% which will be refined or filtered further by Filtered Press; the other is residue with oil which is conveyed back into Screw Press to repress to get rest oil. Cottonseed Oil & Cottonseed Meal

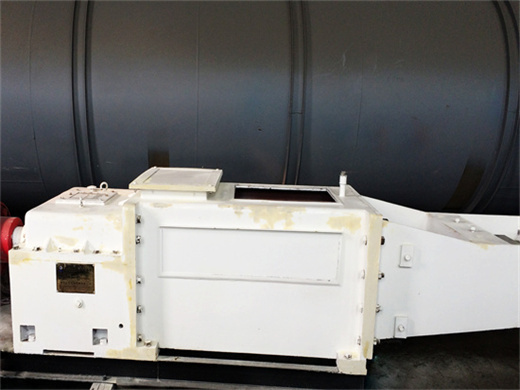

Dewaxing / Winterization/Palm Oil Dry Fractionation

- Type: cooking oil refining machine

- Production capacity: 50-1000 kg/h

- Dimension (L*W) *H): 1400*860*1260

- Voltage: 220/380

- Weight: 280 KG

- Main components: motor, pressure vessel, pump, PLC, others, gear, bearing, motor, gearbox

This is a process of removing components with high melting point (e.g waxes) from some vegetable oils, e.g. sunflower, rice bran and cotton seed oil or partially hydrogenated soya bean oil. Winterizing mainly consists in cooling these oils gradually and filtering them at low temperature in special filters or by centrifugal separators.

Therefore, the crude oil should undergo neutralization and bleaching process before de-waxing. The de-waxing technology people usually refer to indicates two meaning, one is the separation of waxes which are esters of long chain fatty acids and long-chain primary alcohols, the other is the removal of all the impurities-which contain wax

Crude Cotton Seed Oil Refinery Machine | Lingfine Machinery

- Raw Material: cottonseed oil

- power supply: 380V 50HZ three phase 5 wires, can be customized

- Dimension: 9400*840*2050mm, can be customized

- power input: 28KVA

- Conveyor belt: Teflon conveyor belt

- Material: 304# food grade stainless steel

There are 5 steps in cotton seed oil refining, it must include defatting section also called dewaxing. Deacidification and Degumming section of cotton seed oil refining plant. The process of degumming also called dephosphorization remove colloidal impurities in oil . There are hydration, heating, adding acid and adsorption.

Dewaxing is carried out by chilling the oil up to 10-15°C into the crystallizers. Chilling plant is responsible for the low temperature achievement. The crystallizers are equipped with agitation mechanism which is controlled by variable drive so as to have a controlled system and not to break the formed crystals.