Cottonseed Oil Production Line

- Type: cottonseed oil line

- Usage/Application: cottonseed

- Automatic grade: Semi-automatic

- Production capacity:High

- Dimension (L*W*H): According to mini oil refining facilities

- Power (W): According to mini oil refining facilities

- Voltage:220V/380V

- Country: botswana

Dingsheng Machine provides three types of cottonseed oil refining equipment: batch refining equipment, semi-continuous refining equipment of cottonseed oil, and full continuous refining equipment. Cottonseed oil refining equipment can remove various impurities such as collagen -soluble impurities, free fatty acids, pigments, and odors in puff

Prominent Edible Oil Press Machines Manufacturer. Complete

- Type: cottonseed oil refinery machine

- Production capacity: 5TPD-100TPD

- Voltage: 380V/50HZ

- Main components: Motor

- Weight: 580kg

- Dimension (L*W*H): 1820*570*1320mm

10-20T/D Edible Oil Production Line; 1-50T/D Edible Oil Production Line; Oil Refinery Plant. Large Continuous Edible Oil Refinery Plant 20-5000TPD; Batch-type Edible Oil Refining Equipment 1TPD to 20TPD; 10T/D Edible Oil Refinery Plant; 1-5T/D Edible Oil Refinery Plant; Cotton Seeds Oil Refinery Plants; Seed Oil Press. Integrated Screw Oil

CHEMSTA vegetable oil&fats refining production line is used to refine various oils, including soybean oil, rapeseed oil, cottonseed oil, peanut oil, sunflower seed oil, corn germ oil, and rice bran oil. This production line features a capacity of 30-1,000 tons of crude oil per day, and is able to eliminate plasticizer (DEHP) pollution

Cotton Seed Processing, Oil Extraction & Refining Plant

- Usage: cottonseed oil

- Production capacity: High

- Voltage: 380v

- Weight: up to specification

- Dimension (L*W*H): 1360*950*1170mm

- Power (W): up to specification

Cottonseed could either be processed by the traditional crude method of crushing seed without Delinting in un-decorticated form or by scientific processing used for Cotton Seed Processing, which involves removal of De-linters, decortication, separation of hull, expelling, solvent extraction and refining of oil. Scientific processing of Cotton

Cottonseed contains 39-52% hull and 48-61% kernel. The shell contains 0.3 to 1% oil. Cotton kernels contain 30-35% oil and 35-38% protein. Cotton seed contains 0.8% to 1.3% gossypol. The traditional production process of cottonseed oil is pre-pressing or pressing. The following is the flow chart of the cottonseed oil production line.

Steps of Cottonseed Oil Processing Process - Oil Mill Machinery

- Type: cooking oil refining machine

- Production capacity: over 90%

- Dimension (length x width x height): 56x26.5x33 cm

- Voltage: 220 V

- Weight: 12 kg

- Main components warranty: 6 months

The residue & solid powder is separated through automatic oil-dreg separator. After separating, we can get two products, one is crude oil with impurity of 1% which will be refined or filtered further by Filtered Press; the other is residue with oil which is conveyed back into Screw Press to repress to get rest oil. Cottonseed Oil & Cottonseed Meal

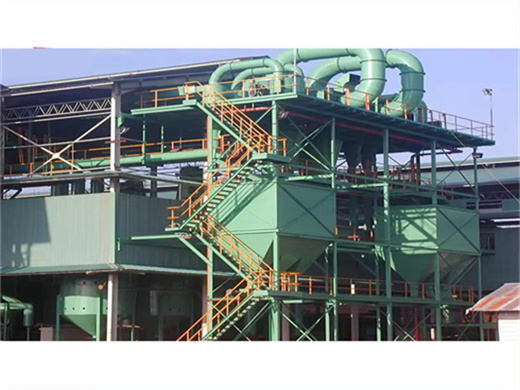

HUATAI Cottonseed Oil Production Line . The common cottonseed oil production line includes three workshops: (There are also other different production craft, our engineers can design the plant according to your requests) 1. Cottonseeds Pretreatment and Prepressing Workshop . 2. Cottonseed Cake Solvent Extraction Workshop . 3.

Cottonseed Oil Production Line - Zhengzhou Siwei Grain & Oil

- Raw Material: cottonseed oil

- Dimension: 40*70 cm (D*H)

- Material: stainless steel

- Weight: 12 kg

- Function: self-heating glass canned bulk honey barrel

- MOQ: 20 sets

Brief Overview of Cottonseed Oil Production Line. 1. The cottonseed oil production process is advanced, with full consideration of low cost, energy saving, environmental protection, and thermal energy recovery and reuse. 2. The process can achieve fully automated control. 3.

This small oil press line can also process various oil seeds and nuts, such as coconut, palm kernel, sesame seeds, sunflower seeds, peanuts, soybeans, etc. With less land space needed, low investment, wide application, and labor savings, this small complete plant is the best choice for starting a small oil milling business!