Cottonseed Oil Processing Plant | Extraction Flow

- Type: cottonseed oil extraction machine

- Usage/Application: cottonseed

- Production capacity: 50-1000kg/h

- Voltage: 220v/380V

- Raw material: Rice bran

- Weight: According to its capacity

- Dimension (L*W*H): According to its capacity

- Country: afghanistan

The common cottonseed oil processing flow: cottonseed - cleaning - shelling - shell kernel separation - embryo rolling - high moisture steaming - pre-pressing - solvent extraction. Cottonseed oil contains a large amount of essential fatty acids, among which linoleic acid has the highest content, which can reach 44.0-55.0%.

Cottonseed Oil Extraction Plant

- Type: cottonseed oil processing machine

- Production capacity: 10T-3000T/D

- Voltage:380V,440V

- Weight:depends on capacity

- Dimension (L*W*H)):depends on capacity

- Power (W): according to capacity

The products of the cottonseed oil processing plant are cottonseed oil, cottonseed meal, cottonseed hull, and soapstock. Features of Cottonseed Oil Processing Plant. 1. Cottonseed oil mill plant has high automation degree, continuous operation, saving labor. 2. The pre-pressed cake has low residual oil rate and is easy for solvent penetration. 3.

Cottonseed could either be processed by the traditional crude method of crushing seed without Delinting in un-decorticated form or by scientific processing used for Cotton Seed Processing, which involves removal of De-linters, decortication, separation of hull, expelling, solvent extraction and refining of oil. Scientific processing of Cotton

Cottonseed Oil Processing - Oilmillmachinery.net

- Usage: cottonseed oil

- Production capacity: 1TPD-1000TPD

- Voltage: 220V/380V/440V

- Weight: According to baking press capacity

- Dimension ( L*W* H): 1200*400*900mm3

- Power(W): 7.5kw

The residue & solid powder is separated through automatic oil-dreg separator. After separating, we can get two products, one is crude oil with impurity of 1% which will be refined or filtered further by Filtered Press; the other is residue with oil which is conveyed back into Screw Press to repress to get rest oil. Cottonseed Oil & Cottonseed Meal

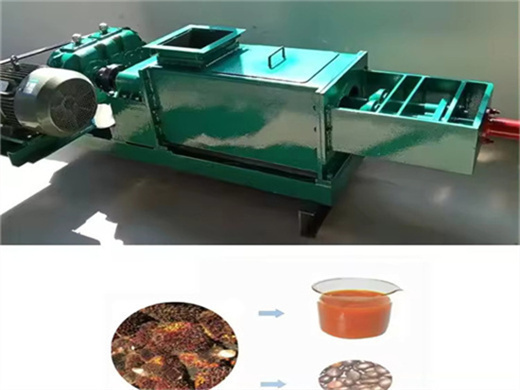

Oil Extraction: After pretreatment, the material is transported to the oil pressing workshop, where the pretreated materials are transported to the cottonseed oil expeller to squeeze the oil out. The whole cottonseed oil extraction process may need several times to ensure the high oil output. Then, the crude cottonseed oil is made and the

Production of Cottonseed Oil - Edible Oil Expeller Machinery

- Type: cooking oil extraction machine

- Production capacity: 20-2000TPD

- Dimension (L*W*H): 1850*880*1750mm

- Voltage: 380V

- Weight: 6000 KG

- Main components: motor, pressure vessel, pump, PLC, gear, bearing, motor

The cell wall of cottonseed oil is destroyed and the billet becomes flake by using the embryo rolling mill, which greatly shortens the oil discharge from the cottonseed, and thus improves the oil production speed and oil yield. Characteristics of cottonseed oil extraction process: 1.The yield of oil is high. The residual oil in the oil can be

Cottonseed oil is extracted from the seeds of cotton plants. Refined cotton seed oil is edible. India, China, Pakistan, USA and Brazil are among the top producers of cotton seed oil in the world. Let us now know about the various aspects of cottonseed oil plant - it's manufacturing process, world market status and other features.

Cottonseed Oil Extraction Plant - Edible Oil Expeller Machinery

- Raw Material: cottonseed oil

- Production capacity: 60-80 kg/h

- Dimension (L*W*H): 1200*400*900 mm

- Voltage: 5.5 kw

- Weight: 320 KG

- Main components: motor, pressure vessel, pump, PLC, gear, bearing, motor, gearbox

Cottonseed kernels contain 0.5%-2.5% of gossypol. After processed by the cottonseed oil refinery plant, the gossypol content in the oil is less than 0.01%. The products of the cottonseed oil processing plant are cottonseed oil, cottonseed meal, cottonseed hull, and soapstock. Features of Cottonseed Oil Processing Plant. 1.

We offer cottonseed processing plants which includes several stages of processing like delinting, dehulling, hullbeating, meats recovery, cooking and conditioning etc.The cooked meats are subjected to oil recovery by expellers. The residual oil contained in the Expeller Cake is recovered through solvent extraction process.