Hongde palm oil machine / FFB oil mill - Palm Oil Production Line

- Type: palm oil processing machine

- Usage/Application: palm fruit, palm kernel

- Production capacity: 5TPD

- Voltage: 220V

- Main components: Motor, Others

- Weight: 22 KG, 22 kgs

- Dimension (L*W*H): 50*53*30 cm

- Country: tanzania

[rev_slider alias=”slider3″ slidertitle=”Slider 2″][/rev_slider] COMPLETE PALM OIL PRODUCTION LINEPalm Oil Engineering Project Specialist PALM OIL MILL PLANT Hongde palm machinery provides a range of palm oil making machines to extract oil from fresh fruit bunches of oil palm. The following is the typical palm oil manufacturing process which might be useful for new investors of […]

palm oil line

- Type: palm oil refinery machine

- Automatic grade: Automatic, Fully automatic

- Production capacity: 20kg/h

- Weight: 7400 kg

- Dimension ( L*W*H): 70*45*65 CM

- Voltage: 180V -240V

Before extracting oil, the palm fruits need to be crushed in digester machines. To augment oil yield, the fruit pulp is also warmed in this process. The mesocarp and nuts can be squeezed together in palm oil making/pressing machine. But if you plan to make Grade A Palm Oil, the palm nut/kernel should be removed before oil pressing section.

Palm oil processing and palm oil mill Palm oil is an edible vegetable oil derived from the mesocarp (reddish pulp) of the fruit of the oil palms. It is naturally reddish in color because of a high beta-carotene content. Palm mesocarp oil is 49% saturated, while palm kernel oil is 81% saturated fats.

Crude Palm Oil Processing, Palm Oil Processing Machine, Palm

- Usage: palm oil

- Production capacity: 150-2500 KG/h

- Voltage: 380/220/400

- Weight: customizable

- Dimension (L*W*H): customizable

- Power (W): customizable

Hongde provides high capacity crude palm oil processing machine production line including palm fruit and kernel pressing, oil refining, oil fractionantion with guaranteed warranty and reliable service.

Palm Oil Refining Machine. Palm Oil Refinery is the main oil machinery and equipment to ensure the quality, grade and edible safety of oil in the palm oil processing process. The palm oil refining machine produced by Henan Hongde Cereals and Oils Machinery Co., Ltd. can flexibly adapt to different production needs with advanced technology

Crude Palm Oil Processing Line Machinery Equipment

- Type: cooking oil refining machine

- After-sales service: Online service

- Structure: Horizontal , Horizontal

- Warranty: 1 year, 1 year

- Press series: Second, Fourth

- Voltage: 380 V, 220 V

Palm oil content of pulp is 49%, and palm oil content of palm kernel is 50%. 5T/H of palm oil project economic benefit analysis According to the current palm oil and palm kernel oil price accounting daily output: (with reference to the market price)

Removing the impurities from crude palm kernel oil. And then the filtered oil will be sent into crude oil storage tank. Machine required: plate filter. It is worth noting that if you want higher oil yield and quality palm kernel oil, Henan Glory Company engineers can also customize a set of solvent extraction processing machine and refining

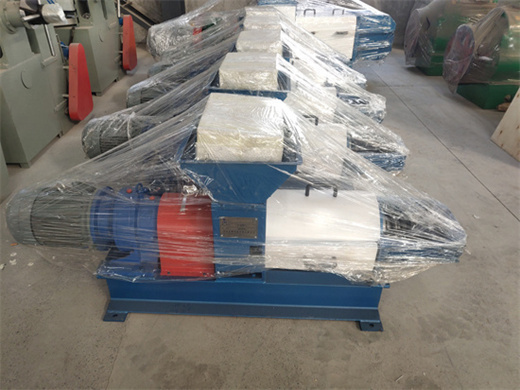

Palm Oil Mill Plant Production Line - Hongde OIL MACHINE

- Raw Material: palm

- Production capacity: 5TPD-100TPD

- Dimension (L*W*H): 1900*500*1300mm

- Voltage: 380V

- Weight: 700 KG

- Main components: Motor

We can offer you a whole line of palm oil pretreatment equipment, palm oil extraction machines, and palm oil refinery machines, and build a palm oil turnkey project from A to Z for you. And we sell single machines too, palm fruit oil pressing machines, palm fruit crushing machines, palm fruit oil fraction machines and so on. GET A QUOTE

Palm oil is extracted from the fruits of the oil palm tree, which is developed in tropical districts of Asia and Africa. While palm oil makers depend on various methods to extracte this oil, the fundamental advances engaged with palm oil creation continue as before. Manufacturers must plant a supply of oil palms, and direct their consideration through development. The fruits of the tree would then be able to be reaped and prepared to discharge the oil. The last advance in palm oil generation includes refining the oil to meet the requests of different clients.