(PDF) Cottonseeds and Crude Peanuts Oils Production

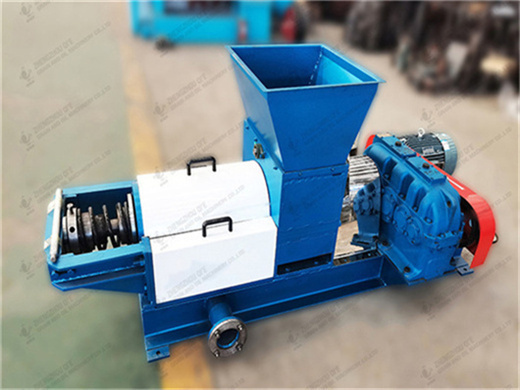

- Type: peanut oil mill

- Usage/Application: peanut, groundnut

- Production capacity: 100 kg/H

- Voltage: 380 V/50 HZ/Three-phase

- Main components: Pressure container

- Weight: 240KG

- Dimension (L*W*H): 700 /800/ 780MM

- Country: tanzania

The p-Anisidine value average was 1.80 for refined cottonseeds oils and 11.65 for crude peanut oils. The Totox averages were respectively 19.37 and 28.36 for refined cottonseeds and crude peanut oils.

Materials used for producing and refining of the cottonseeds

- Type: peanut oil refinery machine

- Production capacity: 10-3000 tons

- Voltage: 380v 440v

- Weight: Depends on the capacity of corn oil manufacturers

- Dimension (L*W*H) ): According to capacity of corn oil manufacturers

- Power (W): As corn oil manufacturers produce every day

Download scientific diagram | Materials used for producing and refining of the cottonseeds and crude peanut oils (A: Electric press for obtaining crude cottonseeds oil, B: tanks for refining the

Crude oil sales price 0 500 1000 1500 2000 2500 3000 Jan-06 Jan-07 Jan-08 Jan-09 Jan-10 Jan-11 Jan-12 Jan-13 Jan-14 Jan-15 Jan-16 Crude peanut oil Palm oil Sunflower oil Current sales price: 1250 US$ / Ton Vegetable oil prices, US$/Ton • Peanut oil is very expensive compared to other food oils

Cottonseeds and Crude Peanuts Oils Production Technology

- Usage: peanut oil

- Voltage: 220 V/380 V/440 V

- Power (W): 18.5 kW

- Certification: ISO9001

- Weight: 2000kg

- Dimension (L*W*H): 1500*1600 *2500mm

The production of peanut oil: a total of 18 peanut oil producers were interviewed in tanzania and Bobo Dioulasso. The production technology of peanut oil is not the same for all producers. These products were in two types (type A and type B). The second type (type B) of production is minority used and intended only for crude peanut oils

Overall, the averages are 10.89 and 56.44 mg/100 g for crude peanut oils and refined cottonseed oil, respectively ( p < 0.05). The α -tocopherol values of cottonseed oils are higher than those

crude peanut oil refined mill equipment factory in tamale

- Type: cooking oil refining machine

- Production capacity: 140-200Kg/h

- Dimension (L*W*H): 1700*1300*1650 mm

- Voltage: 220 v/380 v

- Weight: 1250 Kg

- Main components: Motor

Pressing Oil standard:First class; Function of rice oil refinery plant:refinery oil from crude oil; power:20kw/h; Quality of rice oil refinery plant:Superior International; Residue in cake:less than 6%; Using of rice oil refinery plant:canola refinery oil plant; Capacity of rice oil refinery plant:5TPD-1000TPD

The peanut oil refining process is to transform crude peanut oil into a high-quality edible oil. Include degumming, deacidification, decolorization, and deodorization. info15@cnoilmachine.com 0086-159-3728-9608 0086-159-3728-9608

Study on antioxidant activity of crude peanut oils and refined

- Raw Material: peanut

- Production capacity: 1-2000TPD

- Power (W): 15KW

- Voltage: 380V/50HZ

- Dimension (L*W*H): 1700*1100* 1600mm

- Weight: 1200kg

The oil samples collected were crude peanut oils and refined cottonseed oils. A total of thirty-two (32) samples were collected in 60 mL amber plastic vials and hermetically sealed and stored in icebox for future analysis. Crude peanut oils were collected from production sites and some markets.

By this kind of technology, the residual oil ratio in the oil meal is less than 1%. Peanut oil solvent extraction plant and working process flow chart. 3) Peanut oil refinery plant: After solvent extraction, there are some impurities in crude peanut oil. To get the higher quality final product oil, the crude peanut oil should be refined by oil