Crude Peanut Oil Refining Machine Supplier in ethiopia

- Type: peanut oil machine

- Usage/Application: peanut, groundnut

- Voltage: Na

- Appearance: Vertical

- Customized: Customized

- Press Series: Fifth

- Press Materials: Flowers, Herbs, Plants

- Country: ethiopia

In general, there're 3 types of peanut oil refinery plant, batch type, semi-continuous and full-continuous. 1-2-3-5-10TPD batch type peanut oil refinery plant. 10-15-20-25-30-50TPD semi-continuous peanut oil refinery plant. 50-80-100-150-300-600-2000TPD full-continuous peanut oil refinery plant. Different capacity peanut oil refinery machine

Small Edible Oil Refinery Plant

- Type: peanut oil refinery machine

- Production capacity: 20~2000T/D

- Voltage: 380v/50Hz

- Weight: as per specification

- Dimension (L*W) *H): 1360*950*1170mm

- Power (W) : up to specification

Process almost all kinds of crude oil for edible purpose: vegetable oil, palm oil, palm kernel oil, castor oil, sunflower oil, rice bran oil, soybean oil, sesame oil, cottonseed oil, canola/mustard oil, peanut/groundnut oil, etc. Machine Cost: $21,000~$115,000 (the exact price is based on capacity and other requirements of each equipment)

Spectec techno projects Pvt. Ltd. is a leading company in oil processing, oil mill, oil extraction plants, physical refineries, vanaspati, hydrogenation plants etc. Spectec India is a leading manufacturer of Plant & Machinery, Turnkey Projects for crude oil processing, Edible Oil Refining oil milling. A private oil mill was founded by

Batch Type Small Edible Oil Refining Plant - Oil mill

- Usage: peanut oil

- Main components: Q345R steel plate

- Structure: boiler inner coil

- Fuel: Biomass

- Steam production: 120kw/h--14000kw/h

- Pressure: 1.0 mpa-2.0 mpa

The Batch-type edible oil refining equipment is designed to handle various types of crude oils, including palm oil, soybean oil, sunflower oil, peanut oil, and more. It performs several refining processes in a batch mode, allowing for flexibility and control over the refining process.

The oil content of peanut is approximately 42% to 52% oil. Peanut oil is mainly used for cooking purpose as it contains lots of protein and 80% unsaturated fatty acids like oleic acids and linoleic acids. Peanut oil is in light yellow transparent color and has a fragrant smell, and their taste is very delicious. Groundnut / Peanut Oil Making

Peanut Oil Production Line, Automatic Production Line for

- Type: cooking oil refining machine

- Production capacity: 1t/day-1t/hour-100%

- Dimension (L*W*H): 1055 *805*345mm

- Voltage: 220V/50HZ three-phase

- Weight: 27.1KG

- Main components: motor, motor

Leached oil is refined and sold as ordinary oil. 1. Crude oil refining process flow. Filtration of oil→primary cooling→adding filter aids→secondary cooling→48h precipitation→filtration→refined oil→filter cake. 2. Process description. Primary cooling: The temperature of the crude oil sent from the press workshop is generally 60

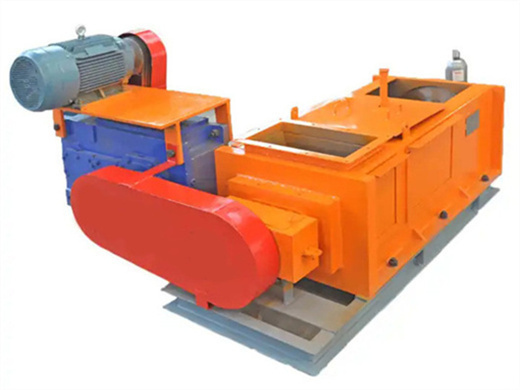

The mechanical oil pressing method uses the power which is generated from the gradual reduction of the volume between the squeezed screw and the pressing chamber, as well as the power generated by the friction between the material and the peanut oil press machine to extrude the oil inside the pretreated peanut flakes.

Complete Facility of Peanut Oil Processing Mill | Edible Oil

- Raw Material: peanut

- Production capacity: According to your needs

- Power (W): 22kw

- Voltage: 380V/50Hz

- Dimension (L*W*H): 2000x1400x1850mm

- Weight: 1200kg

The purpose of peanut pretreatment is to improve the oil yield. Pretreatment machine for peanut oil manufacturing are cleaning sieve, destoning machine, flaking machine, crushing machine, cooking machine and more. Peanut Oil Pressing Machine Pretreated peanuts are transported by conveyor to screw oil expeller to get the crude peanut oils. Screw

Then the cleaned peanut seeds are sent to the oil milling plant to be pressed into oil by oil presses. However, the crude peanut oil usually contains a number of impurities. So for edible oil, the pressed groundnut oil needs to be extracted in the oil extraction plant before the extracted oils are sent to the oil refining plant for further