Sunflower Oil Extraction Process, Methods – A Full Guide

- Type: sunflower oil plant

- Usage/Application: sunflower

- Model NO.

- SRP205

- Certification

- First class

- Press series

- Country: botswana

Sunflower seeds from the oil-type contain about 20% to 30% hulls that are sometimes removed before oil extraction to ensure the quality of both oil and sunflower meal. De-hulling is completed when the seed has a moisture content of 5% after cleaning.

HOW IS SUNFLOWER OIL EXTRACTED? - Grainvest

- Type: sunflower oil processing machine

- Production capacity: 20 tpd-100%

- Voltage: 220 VAC 50 Hz

- Main components: motor, motor

- Weight: 12 kg

- Dimension (length x width x height): 67*35*50 cm

Sunflower oil production has the following manufacturing processes: cleaning of the seeds, grinding of the seeds, pressing and extraction of crude oil from these seeds and then further refining the oil obtained before packaging. A volatile hydrocarbon like hexane is used as a solvent to extract the oil. Cleaning; De-hulling; Grinding; Pressing

Sunflower oil refinery plant: Machines used in large scale sunflower oil refinery plant. Sunflower oil refinery plant has three types, and their processes are different. If you want to know the details, please read the following passages. a. batch type sunflower oil refining machine. b. semi-continuous sunflower oil refinery plant

Agribusiness Handbooks, vol. 2: Sunflower/Crude and Refined Oils

- Usage: sunflower oil

- color: according to customers' requirements

- capacity: according to customers' needs

- Crude oil moisture and volatile matter: ≤ 0.30%

- Solvent consumption: ≤ 2Kg/T (solvent oil No.6)

- Residual oil in flour: ≤ 1%

The average yield of oil obtained by mechanical extraction from sunflower seed is 35 % from unshelled seed of normal moisture content (9%) and 42,5% by pre-press and solvent extraction. 2- SUNFLOWER SEEDS PROCESSING: CRUDE & REFINED OILS 2.1. Process description a) Drying and storage

Crude sunflower oil includes all the impurities from the pressing process or solvent extraction process, and the pigments, bad smell, wax conent, etc. These are the things that will influence the quality of sunflower oil. What's more, crude sunflower oil is forbidden to sell on the market. So, if you want to get high quality of sunflower oil

Sunflower Oil Production Line

- Type: cooking oil extraction machine

- Production capacity: ≥92%

- Dimension (L*W*H): 1970*1280*1910

- Voltage: 380

- Weight: 1100 KG

- Main components: Gearbox, Others

The oil is extracted directly from the sunflower seeds by a screw type oil press machine. Sunflower seeds are cold-pressed (or hot pressed) at a certain temperatures, and the protein-rich cake that remains after the seeds are processed into oil is used as animal feed, retaining 99% of the nutrients in sunflower oil without the use of chemical solvents.

Mixed oil concentration: 18-25%; Supply type: manufacturer; Solvent residual: < 0.07%; Market: all the countries; Product: edible oil; Item: mini crude oil refineries; Oil residue ratio: 1%; Types of Sunflower Oil Making Machines: 1. Cold Press Sunflower Oil Machine: Extracts oil at low temperatures to retain the natural nutrients, flavor,

How is Sunflower Oil Processed?

- Raw Material: sunflower

- Production capacity: 250-300 kg/h

- Dimension (L*W*H): 2100*1400*1700 mm

- Voltage: 220v/380v

- Weight: 950 KG

- Warranty: 1 year

The purpose of grinding is to increase the surface area to be heated during extraction. Sunflower Oil Extraction; The heated sunflower seeds meal is continuously added to the sunflower oil making machine that has slotted barrel at highly progressing pressure from 69000 to 200000 kilopascals. The oil is squeezed out and recovered through the

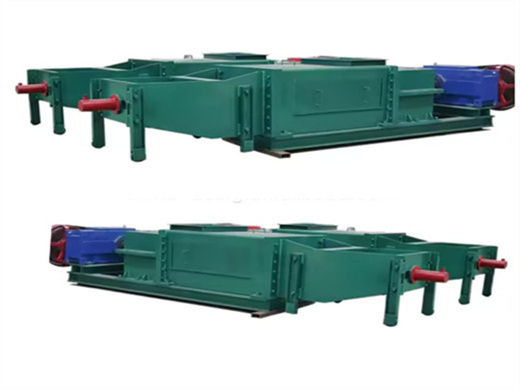

Sunflower oil solvent extraction plant: 1. Sunflower cakes are sent into extractor, then soaked in solvent, at last the mixed oil will flow out of the extractor. 2. The wet sunflower seeds meal are sent into D.T.D.C, through desolventizing,toasting, drying, cooling four steps, at last we can get dry sunflower seeds meal that only contains less