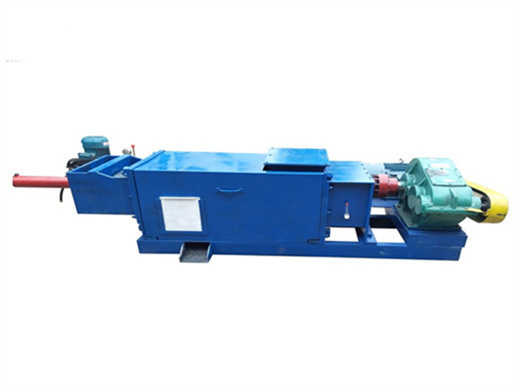

palm oil line

- Type: palm oil machine

- Usage/Application: palm fruit, palm kernel

- Production capacity: 100 TPD

- Voltage: 170 HP

- Main components: motor, bearing, gearbox

- Weight: 14000 KG

- Dimension (L*W*H): 4875t1828 t1985

- Country: nairobi

Before extracting oil, the palm fruits need to be crushed in digester machines. To augment oil yield, the fruit pulp is also warmed in this process. The mesocarp and nuts can be squeezed together in palm oil making/pressing machine. But if you plan to make Grade A Palm Oil, the palm nut/kernel should be removed before oil pressing section.

BEST Palm Kernel Crushing Machine | Palm Kernel Processing Plant

- Type: palm oil refinery machine

- Production capacity: 45 kg per hour

- Voltage: 220-240 volts

- Warranty: 2 years

- Weight: 67 KG

- Dimension (L*W*H): 840*240*540 mm

Palm Kernel and Shell Separation: The kernel is sent to palm kernel oil extraction machine, while palm kernel shells are sent to boiler to be used as fuel. Separating the shells from the kernel can not only greatly improve the oil yield and production efficiency, but also help reduce the wear of oil extraction equipment.

Palm Oil Refinery is the main oil machinery and equipment to ensure the quality, grade and edible safety of oil in the palm oil processing process. The palm oil refining machine produced by Henan Huatai Cereals and Oils Machinery Co., Ltd. can flexibly adapt to different production needs with advanced technology and modular design:

Highly Efficient Palm Kernel Oil (PKO) Processing Machines at

- Usage: palm oil

- Production capacity: 200 tpd pretreatment

- Voltage: 220V/380V/440V

- Weight: 850 KG

- Dimension (L*W) *H): 5432*2636*2345

- Power (W): 15kw

The quality of palm kernel oil obtained through above processing steps is high and enough to reach the standard of cooking oil. If there are special requirements, the palm kernel oil needs to be refined at professional Palm Kernel Oil Refining Plant. PKO Refinery - Edible Oil Refining Machine

Palm oil production line. Huatai Oil Machinery is a leading company in the field of palm oil pressing and palm kernel oil processing and equipment, we can provide completely set of 5-120tph palm oil production line. Our company offers a range of products and services for the palm oil extraction, palm kernel oil extraction, crude palm oil

Palm Oil Processing Production Line

- Type: cooking oil refining machine

- Production capacity: 1-2000TPD

- Power (W): 5.5kw

- Voltage: 220V

- Dimension (L*W* H): 46*32*36cm

- Weight: 130kg

Palm oil processing and palm oil mill Palm oil is an edible vegetable oil derived from the mesocarp (reddish pulp) of the fruit of the oil palms. It is naturally reddish in color because of a high beta-carotene content. Palm mesocarp oil is 49% saturated, while palm kernel oil is 81% saturated fats.

(Related Post: Small Palm Kernel Oil Extraction Machine>>) Crude palm oil can be refined and fractionated to obtain products with different melting points, which have a wide range of uses in the catering industry, food industry and oleochemical industry, respectively, with broad investment prospects. In other words,starting a palm oil

Palm Oil Machine - Palm Oil Production Line

- Raw Material: palm

- Production capacity: 9000-10000 kg/h

- Power (W): 18.5 kW

- Voltage: 380 V

- Staff requirement: 1-2 people to operate the linseed extract oil machine

- Space requirement: 60 -80 square meters for linseed extract oil machine

The pulp part is processed by palm oil pressing machine to extract crude palm oil; the kernel part is crushed and extracted by a special palm kernel press. The crude palm oil is refined by palm oil refining machine to remove impurities, sourness and color, and it can become clear edible oil in the supermarket; if the customer needs to produce

Palm Kernel Oil Solvent Extraction Plant is recommended for large Palm Kernel Oil Mill with high capacity. However, For the purposes of small-scale operations it is sufficient to mention the solvent extraction process is an alternative for high capacity mills. However the process is not recommended for small enterprises. Basic Unit Operations