Food oil processing equipment

- Type: soybean oil refinery equipment

- Usage/Application: soybean

- Outgoing video inspection: Provided

- Machinery test report: Provided

- Flow: 2-50 TPD

- Main components: PLC, motor, bearing, gearbox, motor, pressure vessel, gear, pump

- Main components marketing warranty: 1 year

- Country: nigeria

QI'E Grain and Oil Machinery Co., Ltd is a manufacturer of edible oil making machine, and founded in 1976 with well-equipped testing facilities and strong technical force. With good quality, reasonable prices and stylish designs, our products are extensively used in edible oil production and other industries.

Soybean Oil Extraction Plant Project

- Type: soybean oil refinery machine

- After-sales Service: 24X7 After-sales Service

- Warranty: 3 Years for Main Structure

- Voltage: 380V

- Press Series: Third

- Structure: Horizontal

Choose a Strong Soybean Oil Extraction Equipment Manufacturer. Powerful soybean oil extraction equipment manufacturers can not only provide quality-guaranteed equipment, but also customize soybean oil extraction plans and soybean oil processing plant equipment layouts for manufacturers to ensure the smooth operation of the factory.

We can provide edible oil refining plant equipment with capacity ranging from 50 t/d to 4,000 t/d for soybean oil, rapeseed oil, sunflower seed oil, cottonseed oil, rice bran oil, palm oil, corn oil, peanut oil, linseed oil, animal fats and oils, chicken fat, butter, fish oil and etc. Refining is the last step in edible oil processing.

Top 60 Oil Refinery Equipment Suppliers in 2025 | ensun

- Usage: soybean oil

- Production capacity: 1-500T/D

- Voltage: 380V-415V

- Weight:depends on machine mode of cooking oil

- Dimension (L*W*H):depends on cooking oil machine mode

- Power (W) :depends on cooking oil machine mode

Oil refinery equipment refers to the machinery and tools used in the processing of crude oil into valuable products such as gasoline, diesel, and other petrochemicals. This equipment includes a variety of components such as distillation columns, heat exchangers, reactors, and pumps, all of which play critical roles in the refining process.

Animal Fats Oil Refining Equipment,the process adopts the international advanced level of "combination deacidification tower", deacidification ability, from the tower, tower packing, liquid distributor, liquid redistributor, support grid and the composition of gas and liquid imports and exports.On the basis of the traditional refining,a unique

Custom Soybean Oil Refining Equipment for Efficient Oil

- Type: cooking oil refining machine

- Production capacity: 5-500 TPD

- Weight: 500 TONS

- Voltage: 440 V

- Certification: ISO,CE

- After-sales service provided: Engineers available to service machinery abroad.

This article discusses the importance, functionality, and benefits of custom soybean oil refining machines in the oil industry. Understanding Soybean Oil Refining. Soybean oil refining is a critical process that involves several steps to ensure that the oil extracted from soybeans is safe, palatable, and free from harmful substances.

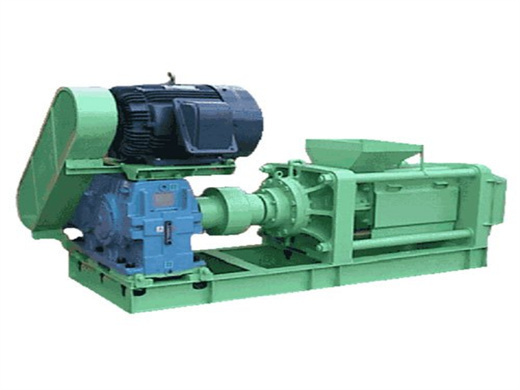

The main products include screw oil presses, solvent extraction equipment, refining equipment, etc., covering the complete production chain from soybean pretreatment, oil pressing to oil refining. The equipment design adopts advanced automatic control system, which is easy to operate and has the characteristics of high output, low energy

Company Overview - Henan Mingxin Machinery Co., Ltd.

- Raw Material: soybean

- Production capacity: 5-100T/H

- Power ( W): 100kw

- Voltage: 220V/380V/440V

- Dimension (L*W*H): Depends on capacity

- Weight: Depends on capacity

Main categories: Oil Press Machine, Oil Press Production Line, Oil Refinery Equipment Ranked #1 Oil Pressers class _i18n_mod_start_`shopmodule.shopsign.rankdelivery_i18n_mod_end_ ODM services available Design-based customization Multi-Language capability: Sample-based customization

A custom soybean oil refined machine integrates advanced technology to optimize each step of the refining process. Unlike standard machines, custom solutions are designed based on the specific needs of the producer—taking into account factors like production volume, oil quality specifications, and budget constraints .