Palm Kernel Oil Manufacturing Process - Oil Expeller

- Type: palm oil expeller

- Usage/Application: palm fruit, palm kernel

- Production capacity: 500

- Voltage: 380

- Warranty: 3 years

- Weight: 12000 KG

- Dimension (L*W*H): 6000X5000X5000

- Country: johannesburg

Because of their high oil content, Palm kernels have to be subjected to 2 stage pressing for maximum oil yield. The residue from First Stage Press is then transferred to a second palm kernel oil expeller machine for final crushing. The Oil &foots collected from both the First & Second Stage Pressing is delivered to the crude oil Filtering section.

Expeller shaft and worm assembly | Download Scientific Diagram

- Type: palm oil processing machine

- Voltage: 220 V/380 V/440 V

- Power (W): 18.5 kW

- Certification: ISO9001

- Weight: 2000kg

- Dimension (L*W*H): 1500*1600 *2500mm

In a span of 2 years, 15 palm oil refineries were already up and running in Malaysia, sending the country straight to the top as being one of the world's leading palm oil exporters.

The above is the mainly introduction of palm oil mill (suitable for capacity above 15tph). Any question about palm oil mill process flow chart diagram and any capacity palm oil processing machine , please feel free to contact Henan Doing Company. You will get more thank you think.

Fig 1: Groundnut Oil Expeller Assembly diagram Fig 2

- Usage: palm oil

- Production capacity: 5-8kg/time

- Voltage: 220V/380V

- Key selling points: Automatic

- Warranty: 1 year

- Dimension (L*W*H): 900x850x1550mm<br /Weight: 880 KG

The efficiency of the expeller and production capacity were detected to be 60.3% and 35 kg/h, respectively.The basic properties of the PKO concur with those of vegetable oils and Jatropha oil

The expeller can be used for small scale groundnut oil extraction in the rural and urban communities. Groundnut Oil Expeller Assembly diagram Fig 2: Isometric view of the hopper

PALM OIL PROCESSING - Palm Oil Mill Machine Leading

- Type: cooking oil extraction machine

- Production capacity: 5-500 TPD

- Voltage: 440 V

- After-sales service provided: Engineers available to service machinery abroad.

- Certification: ISO,CE

- Weight: 500 TONS

3. 1 General processing description. Research and development work in many disciplines – biochemistry, chemical and mechanical engineering – and the establishment of plantations, which provided the opportunity for large-scale fully mechanised processing, resulted in the evolution of a sequence of processing steps designed to extract, from a harvested oil palm bunch, a high yield of a

Crude Palm Kernel Oil Expeller Cake (PCK) Oil A B C Figure 4. Mechanical palm kernel crushing process flow chart. Figure 5. Mechanical screw press for palm kernel oil extraction. The kernel meal is agitated at each stage and flows down from the top compartment of the heated stack cooker. Temperature and moisture content are important

5. PALM KERNEL OIL EXTRACTION

- Raw Material: palm

- Production capacity: 100% cooking separator machine

- liPower (W): 10-50kw

- Voltage: 220V/380V/440V

- Dimension (L*W*H): 1200*400*900mm3

- Weight: According to processing capacity

The released oil is periodically skimmed from the top. Today, there are stations in villages that will accept well-dried kernels for direct extraction of the oil in mechanised, motorised expellers. (Fig. 20, 21) Fig. 20 Whole palm kernel expeller (CAMEMEC, lusaka) Fig. 21 Palm kernel expeller (O.P.C., Cameroon)

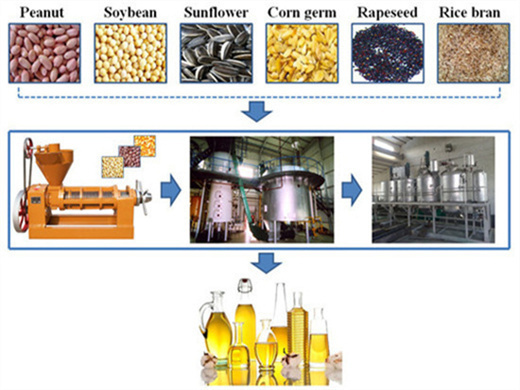

Oil extraction is the process of recovering oil from oil-bearing agricultural products through manual, mechanical, or chemical extraction. The agricultural products are classified into oil-seeds (cotton, castor, sunflower, etc), nuts (coconut, groundnut, sheanut, etc) and mesocarps or fruits (oil palm).