Palm Oil Processing Machine for Sale

- Type: peanut oil processing machine

- Usage/Application: peanut, groundnut

- Flow: 150 Tons/day

- Voltage: 380V

- Weight: 65Tons

- Dimension (L*W*H): 50m* 20m*22.5m

- Power: 140KW

- Country: johannesburg

A palm oil processing machine is either a single machine used in the oil processing sequence or a set of palm oil machines designed for automated or semi-automated palm oil processing. The purpose of palm oil-making machines is to digest, press, clarify, purify, and refine the oil.

Professional Palm Oil Digester Machine, Palm Fruit Digester

- Type: peanut oil processing machine

- Voltage: 220 V/380 V

- Power (W): 18.5 kw

- Certification: ISO9001

- Weight: 2000kg

- Dimension (L *W*H): 1500*1600*2500mm

If you are interested in palm oil digester machine or other palm oil processing equipment, please contact us with hesitation! Kindly give me a quotation for a 2TPH mini palm oil mill with the following equipment: Thresher, cooker, auger conveyor, digester, presser, clarifier and hydraulic machine that can cut big ffb to small sizes.

Peanut oil pretreatment and prepressing section is the basic parts for a peanut oil processing machine.This section includes:cleaning,crushing,soften,flaking,roaster etc process to adjust the peanut seed into the best condition for oil pressing,easy to press oil out and easy for next peanut oil production section.

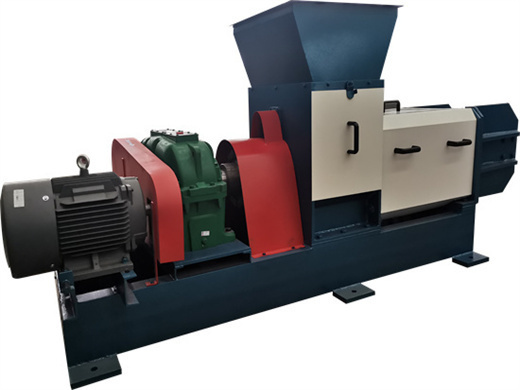

integrated oil palm fruit digester-separator-screw press

- Usage: peanut oil

- Production capacity: 30T-300T/D cooking oil solvent extraction machines

- Voltage: 380v or according to local voltage

- Weight: 1050 KG of cooking oil solvent extraction machinery

- Dimension (L*W*H ): 430*230*350 of cooking oil solvent extraction machines

- Power (W): According to the capacity of cooking oil solvent extraction machines

It is the best selection for small capacity Palm Oil producing customers. The final oil is edible red oil. You can refinery or directly for edible.We also could supply bigger capacity palm fruit oil press machine for whole line palm oil processing plant. Small scale palm oil press machine in our factory Technical parameters of palm oil screw

The major components of palm fruit digester machine include an electric motor, feed hopper, horizontal digesting unit, cake breaking unit, auger separating unit, screw press and discharging outlets for palm nut, palm oil and pressed fibre. Palm fruit digester machine. What is the priciple of palm fruit digester machine?

Best Solutions for Palm Oil Processing, Premium Machinery

- Type: cooking oil extraction machine

- Production capacity: 20-2000TPD

- Power (W):Standard

- Voltage:380V

- Dimension (L*W*H):standard

- Weight:standard

Palm Oil Processing Plant - Digesting System. The purpose of digestion in palm oil processing plant is to rupture the oil-bearing cells of fruit and release the palm oil. The digester is a steam-heated cylindrical vessel. In the digester, there is a central rotating shaft carrying a number of beater arms which is used to pound the fruit.

Before extracting oil, the palm fruits need to be crushed in digester machines. To augment oil yield, the fruit pulp is also warmed in this process. The mesocarp and nuts can be squeezed together in palm oil making/pressing machine. But if you plan to make Grade A Palm Oil, the palm nut/kernel should be removed before oil pressing section.

Peanut Oil Processing Plant - Oil Mill Machinery

- Raw Material: peanut

- Production capacity: 98~100%

- Weight: 8000 KG

- Dimension (L*W*H): 12*7*7 feet

- Main components warranty: Others

- Main components: Other

(1) Peanut oil is extracted by pure physical pressing method, and the whole peanut oil processing process completely avoids the contact between raw materials and chemical solvents; (2) During peanut oil processing, unfavorable refining processes such as solvent leaching, alkali refining, deodorization, etc., which affect the quality of refined

High Working Efficiency Palm Oil Screw Press YKL Group of Companies is one of the world’s largest Palm Oil Machine Manufacturer for KCP and EFB Industry. Headquartered in Muar, Johor and established since 1973, YKL is present in more than 20 countries around the world, and our over 500 customers are supporting YKL’s plan to uphold more