How to Start a Palm Oil Processing Company?

- Type: palm oil plant

- Usage/Application: palm fruit, palm kernel

- Plate Type: Automatic T-shirt Printing Machine

- Automatic Grade: Automatic T-shirt Printing Machine, Automatic

- Dimensions (L*W*H): 2.36*1.1*1.5m

- Voltage: 220V/380V

- Color and page: automatic t-shirt printing machine

- Country: indonesia

A good quality palm oil processing machine will save you a lot of time and money in the long term. So it is necessary that you choose the machines carefully. For effective running of your palm oil processing plant, you will need to hire competent employees. Advertise vacancies for candidates experienced in the field of palm oil processing industry.

Understanding Palm Oil Processing Plant Cost

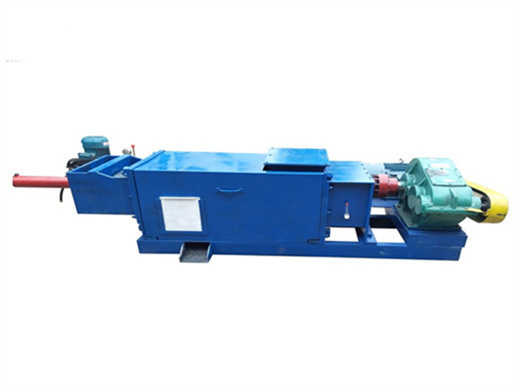

- Type: palm oil processing machine

- Production capacity: 98%

- Voltage: 220V/380V/440V

- Weight: 1050 KG

- Dimension (L*W*H): 1610x615x1260mm

- Power (W): 10-50kw

Single Palm Oil Press Machine Price: Referring to single screw pressing type of palm oil processing machine, a small oil press is generally priced at around $2,000.00 - $3,000.00, while for complex palm oil press machine for industiral oil mill plant, with a main motor of 18.5 kW and have a packing dimension of 255 x 170 x 205 cm, the price is

What sets us apart from the competition is our unwavering focus on customer satisfaction. We understand that each palm oil milling project is unique, and that's why we offer tailored solutions to suit your requirements. Whether you're a small-scale producer or a large-scale plantation, we have the right equipment and expertise to support your operations. Welcome to contact us for your plam oil milling business plan design,

Palm Oil Production Line. Tailor-made Palm Oil Mill Plant

- Usage: palm oil

- Production capacity: 40-50 kg/h

- Voltage: 220 V/380 V

- Residual oil ratio: 1%

- Weight: 250kg

- Dimension (L*W*H): 1200*800 * 1160mm

Palm Oil Refinery is an important process in the palm oil mill plant to ensure the quality and safety of palm oil. It’s recommended to refine crude palm oil through our palm oil refining machines to get high-quality palm oil that is easy to store and can priced high. Refined palm oil can be packed and labeled for the local or global market.

While native to Africa, oil palm trees were introduced to Southeast Asia over 100 years ago as ornamental plants, but countries eventually began making oil. Since then, Indonesia and Malaysia have become significant sources of palm oil production, and they produce around 85% of the global supply. 42 other countries also produce palm oil.

What are the steps in making palm oil? - Palm oil extraction

- Type: cooking oil extraction machine

- Production capacity: 450-7000 kg/h

- Power (W): 1.5 KW

- Voltage: according to customer demand

- Dimension (L*W*H): 1050*950*1650

- Weight: 850kg

The photo of packaged palm fruit oil. The above are the steps in making palm oil. In conclusion, the palm oil making process is intricate and demands precision at every step, from the initial care of palm trees to the final stages of packaging the refined product. Each stage plays a crucial role in determining the quality and yield of the oil.

Sterilization as the first step in palm fruit pressing is critical to the quality of the final production-- palm oil. The purpose of sterilization process is, inactivate the activity of lipase and prevent the rise of free fatty acids; make the palm fruit easier to fall off from the fruit bunch; and soften the peel and make the oil easier to separate out.

Palm Oil Business Plan Proposal Sample Prepared By

- Raw Material: palm

- Production capacity: 100%

- Power (W): Capacity

- Voltage: Local voltage

- Dimension (L*W*H): 2000x1400x1850mm

- Weight: 880kg

This process will ensure maximum oil yield and maintain the quality of the extracted oil. Filtering and Clarification: The extracted oil will go through a series of filtration and clarification steps to remove impurities and ensure the final product meets industry standards. This will result in high-quality, clear palm oil.

Before extracting oil, the palm fruits need to be crushed in digester machines. To augment oil yield, the fruit pulp is also warmed in this process. The mesocarp and nuts can be squeezed together in palm oil making/pressing machine. But if you plan to make Grade A Palm Oil, the palm nut/kernel should be removed before oil pressing section.