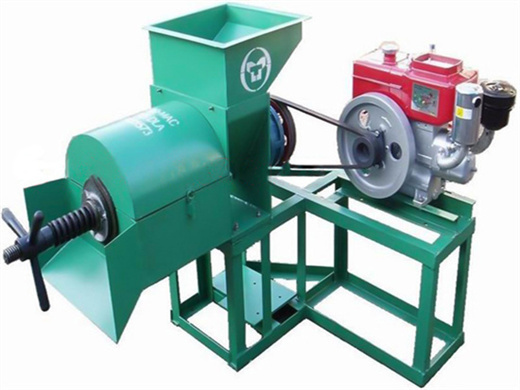

Cottonseed Oil Extraction Plant

- Type: cottonseed oil plant

- Usage/Application: cottonseed

- Production capacity: 1-100T/DAY

- Voltage: 380V, 380V

- Main components: Motor, cooking oil processing machine

- Weight: 1180 KG

- Dimension (L*W*H): 2460*1950*1220mm

- Country: afghanistan

The products of the cottonseed oil processing plant are cottonseed oil, cottonseed meal, cottonseed hull, and soapstock. Features of Cottonseed Oil Processing Plant. 1. Cottonseed oil mill plant has high automation degree, continuous operation, saving labor. 2. The pre-pressed cake has low residual oil rate and is easy for solvent penetration. 3.

Cottonseed Oil Mill Plant

- Type: cottonseed oil processing machine

- Production capacity: 1TPD-1000TPD

- Voltage: 220V/380V

- Weight: 30 tons

- Dimension (L*W*H): 1.5*2.6* 3.6 M

- Power (W): 15KW

Undecorticated Cottonseed obtained after Delinting process can be used as a raw material for Cottonseed Oil Extraction Plant. Cottonseed contains 18 – 20 % oil content. After a single stage pressing, about 6 – 7 % residual oil is left in the cottonseed meal which is an excellent source of Cattle Feed. The working principle of the cotton

Cottonseed oil is extracted from the seeds of cotton plants. Refined cotton seed oil is edible. India, China, Pakistan, USA and Brazil are among the top producers of cotton seed oil in the world. Let us now know about the various aspects of cottonseed oil plant - it's manufacturing process, world market status and other features.

Haris Obaid Cotton & Oil Process Factory – Haris Obaid Cotton

- Usage: cottonseed oil

- Voltage: 220 V/380 V/440 V

- Power (W): 15 KW

- Certification: ISO9001

- Weight: 30 tons

- Dimension (L*W*H): 1700*1100*1600mm

Cotton & Oil Process Factory is a place where traditional values blend with modern innovation at the core of the agricultural sector. We have a strong legacy and are dedicated to upholding high standards, positioning ourselves as a top processor of premium cotton and oil products for domestic and global markets.

Within the cottonseed oil processing plant, oils extracted from cottonseed must be refined to remove gossypol, a naturally occurring toxin that protects the cotton plant from insect damage. Cottonseed meal is a good source of protein. It is the byproduct remaining after cotton is ginned and the seeds crushed and the oil extracted.

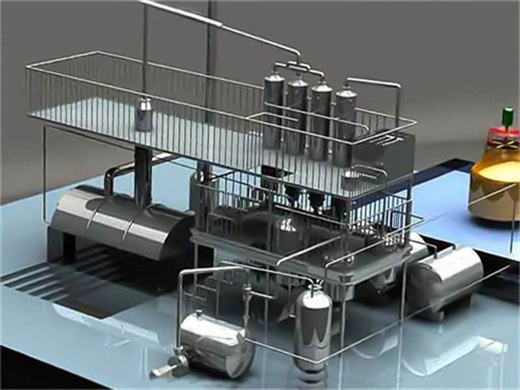

Automatic 200 TPD Cottonseed Oil Processing Plant installed

- Type: cooking oil extraction machine

- Main components: PLC, bearing, motor, pressure vessel, gear, pump

- Power: 25kw

- Voltage: 220v

- Dimension (length*width*height): 20*30*9

- Weight: 40000 kg

The following are the industrial processes which take place during a large scale fully automatic cottonseed oil Processing factory. Read more about how to start a cottonseed oil mill plant. Cleaning. First, need to remove inorganic impurities (metals, dust silt or pebbles), oil impurities (asymmetry seeds, grain of impurities, grain of insects

The production of our refined cottonseed oil begins with the harvesting of the cotton plant. After the fibers have been separated for use in the textile industry, the seeds remain. These seeds are cleaned and freed from foreign matter and cotton lint. Next, the seeds are ginned and hulled, whereby the hulls are removed and used as a by-product.

Cottonseed Oil Processing Plant | Extraction Flow

- Raw Material: cottonseed oil

- Local Service Location: Egypt, Peru, Thailand, Bangladesh, Kazakhstan, Nig

- Function: High temperature sterilization

- Oil Press: Screw Press for fruits for special cooking

- Material: Carbon steel

- Outgoing inspection video: provided

Cottonseed Oil Decolorization. The main purpose of bleaching is to remove pigments from cottonseed oil to improve the color and appearance of the oil. First, we need to heat the degummed (or deacidified) cottonseed oil to 110-120°C. Second, add 0.5-1.5% of an adsorbent such as activated carbon or clay.

Cottonseed oil solvent extraction plant . September 19, 2017 18:49; Oil solvent extraction process; Chat Online; Get price; Cottonseed oil solvent extraction plant is using organic solvent to dissolve oil contained in the oilseed (pressed cake, flake, expansion material) by oil extractor, and then the oil will be separated from the solvent by a series of evaporator, condenser, stripping tower etc.