palm oil press machine d100 in botswana

- Type: palm oil processing plant

- Usage/Application: palm fruit, palm kernel

- Production capacity: 1-2000TPH

- Voltage: 220V/380V

- Weight: 1200kg

- Dimension (L*W*H): 2000x1400x1850mm

- Power ( W): 18.5 KW

- Country: botswana

Small scale palm oil mill plant generally refers to the palm oil processing production with the capacity below 20 ton per day. We have two small palm fruit processing solutions for your! One is mini palm oil mill plant for 1~10 ton/day factory, and the other one is 10~20 ton/day palm oil milling plant for small and medium-sized factory .

The customer in botswana, Cote d 'Ivoire purchased a set of

- Type: palm oil processing machine

- Production capacity: 100~1000T/D, 100%

- Voltage: 380v

- Weight: 38 tons, changed according to capacity

- Dimension (L*W*H): according to specification

- Power (W): 98kw

Small scale palm oil processing plant projects. Palm oil, as the most widely-accepted oil product in the world, has a huge market. More and more people want to do this business. If you are interested in this business and want to buy high quality palm oil processing machine at factory price, please contact us.

Claude is also a recognized palm oil farming expert with years of expertise from his family's ownership of a several thousand hectares palm oil farming operation. He is the leader of a palm oil farmers’ cooperative that provides AgriSmart with pods for pressing and processing into raw palm oil. Mr. Dutauziet manages AgriSmart, Inc. palm oil

small Palm Oil Line in botswana | QIE GROUP

- Usage: palm oil

- Production capacity: 50T~200TPD

- Voltage: 220V~380V

- Certification: ISO9001

- Dimension (L*W*H): 1200*400*900mm3

- Power (W) : 55kw

Supply turnkey palm oil pressing plant and all kinds of quality palm oil machines including palm oil press, palm oil expeller and filter with competitive price. Send an inquiry now and tell us your budget, situation and other requirements. Then we can guide you starting palm oil pressing and refinery business step by step.

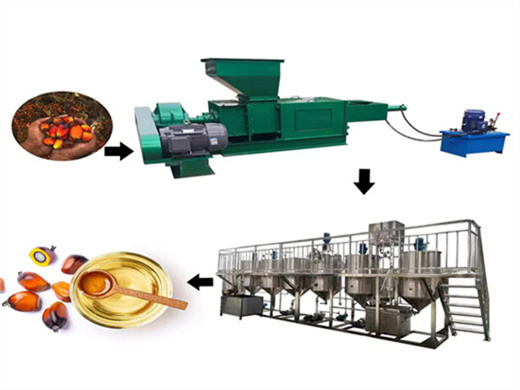

Main Station of Palm Oil Extraction Plant( Whether it is a small scale palm oil machine or large scale palm oil processing plant all include the following station): 1) Palm fruit reception station; 2) Palm fruit sterilizing station; 3) Palm fruit threshing station; 4) Palm fruit digesting & pressing station; 5) Crude palm oil clarification station;

Small Scale Palm Oil Mill Plant, Equipmentfor 1-20t/d Production

- Type: cooking oil extraction machine

- Production capacity: 1-100T/D

- Voltage: 380V/ 440v

- Weight: depends on capacity

- Dimension (L*W*H): depends on capacity

- Power (W) : 20-50KW

Small scale palm oil mill plant generally refers to the palm oil processing production with the capacity below 20 ton per day. We have two small palm fruit processing solutions for your! One is mini palm oil mill plant for 1~10 ton/day factory, and the other one is 10~20 ton/day palm oil milling plant for small and medium-sized factory.

For mini palm oil mill plant with 1~10 ton per day production output, the processing flow is relatively simple, including threshing, digesting and sterilizing, oil pressing and oil filtering. One of the reasons why small scale palm oil mill are very common in the global market including Indonesia and south africaia is that they are affordable and they

Red Palm Oil Production Machine Palm Oil Press Production

- Raw Material: palm

- Certification: ISO CE

- Residual oil in cake: 1%

- Product type: cooking oil processing machine

- Keyword: cooking oil processing machine

- Solvent: n-hexane

The steps for setting up a crude oil milling plant from scratch include feasibility study, factory site selection and construction, Process flow design, equipment selection, workshop equipment layout design, equipment installation, environmental protection, project budget cost analysis, etc...

Multiple crystallisers are used in the series to maximise the use of filter through good planning. It is important to note that fractionation is quite modular technology and very often results in palm oil mill plant. Several water tanks (two to four), all at different temperatures, can be installed in order to maximise heat recuperation while keeping all cooling medium in a closed loop, but this can just as well be done with a single tank feeding chilled water to the crystallisers while steam is added to supply heat and normal cooling water is fed directly from a clean cooling tower. The fractional crystallisation of triglyceride oil is a slow process. The whole filtration and the squeezing operation can take from 30 to 90 minutes.