How a Small Palm Oil Mill Plant is Set Up?

- Type: palm oil plant

- Usage/Application: palm fruit, palm kernel

- Voltage: 220V/380V

- Power (W): according to the specifications of Plam oil refinery production line

- Certification :ISO9001

- Weight: according to the specifications of the production line of Plam oil refinery

- Dimension (L*W* H): according to the specifications of the production line of Plam oil refinery

- Country: mozambique

An interesting thing about the global palm oil market is that it needs mini and small palm oil mill plants in order for its marketing operations to be successful. Normally, a mini scale plant usually produces between 1-10 tonnes of palm oil daily while a small scale plant can process between 10-20 tonnes per day.

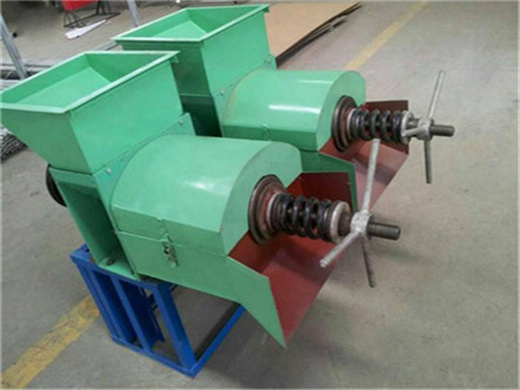

Digesting Process-Palm Oil Digester Machine & Palm Fruit

- Type: palm oil processing machine

- Production capacity: 5TPD-100TPD

- Voltage: 220V/110V

- Main components: motor, gearbox

- Weight : 10.5KG

- Dimension (L*W*H): 37X16X36CM

Palm oil pressing line refers to the palm oil production process to extract crude palm oil out from fresh palm fruit bunches(FFB). The standard palm oil production process mainly includes seven steps.

What sets us apart from the competition is our unwavering focus on customer satisfaction. We understand that each palm oil milling project is unique, and that's why we offer tailored solutions to suit your requirements. Whether you're a small-scale producer or a large-scale plantation, we have the right equipment and expertise to support your operations. Welcome to contact us for your plam oil milling business plan design,

Palm Oil Processing Plant Report 2025: Setup and Cost

- Usage: palm oil

- Nominal input voltage: 220 V

- Nominal duty cycle at 40°C: 60

- Nominal Output Current: Other

- Nominal Output Voltage: 220 V

- Max. Load Power Capacity: Other

Palm oil is a kind of vegetable oil derived from the mesocarp of the fruit of the oil palm tree (Elaeis guineensis). Saturated and unsaturated fatty acids rich, it is semi-solid at room temperature and extensively used in food, cosmetics, and biofuels because of its oxidative stability, long shelf life, and high hectare yield.

Process: The palm fruits are sent to a digester where they are heated to 85°C–90°C and mashed through stirring and squeezing, to destroy the palm skin, separate the palm pulp and nuts, and pound the palm pulp, helping to release the oil in the palm oil pressing process. In small palm oil mill plants, the palm fruit digestion process is

Palm fruit digester machine in palm oil extraction process

- Type: cooking oil extraction machine

- Production capacity: 1tpd

- Dimension (L*W*H): according to capacity<br /Weight: 1000 KG

- Voltage: 380v

- Main components: engine, gearbox

- Oil type: cooking oil

The vertical palm fruit digester is more suitable for the palm oil production process. Various types palm fruit digester machine. Features of palm fruit digester machine: 1, Easy to operate and maintain; 2,Damage palm fruit cell structure,conduce to extarct palm oil from screw type palm oil press machine; 3, Automatic control, high oil yield;

Batch palm oil refining equipment is suitable for ≤20tpd, small cost, equipment covers less area, convenient operation, suitable for a variety of oil flexible replacement, and also includes four refining equipment sections. 0.5-2tpd can be refined by electric heating, all stainless steel material, low cost; 2-20tpd can use heat conduction oil

Carthage Grains CHP Plant, mozambique

- Raw Material: palm

- Production capacity: high

- Power (W): depends on the capacity of the neem seed oil making machine

- Voltage: 220V/ 380 V/440 V

- Dimension (L*W*H): Depends of the capacity of the neem seed oil making machine

- Weight: Depends on the neem Capacity of the seed oil making machine

Home → Actualités → Carthage Grains CHP Plant, mozambique Carthage Grains is the leader in the Maghreb in the trituration of the soya bean: production of oil and soybean meal. The process of Carthage Grains consumes electrical and thermal energy in the form of steam (30 to 35 tonnes per hour at 12 bar pressure).

Palm oil is extracted from the fruits of the oil palm tree, which is developed in tropical districts of Asia and Africa. While palm oil makers depend on various methods to extracte this oil, the fundamental advances engaged with palm oil creation continue as before. Manufacturers must plant a supply of oil palms, and direct their consideration through development. The fruits of the tree would then be able to be reaped and prepared to discharge the oil. The last advance in palm oil generation includes refining the oil to meet the requests of different clients.