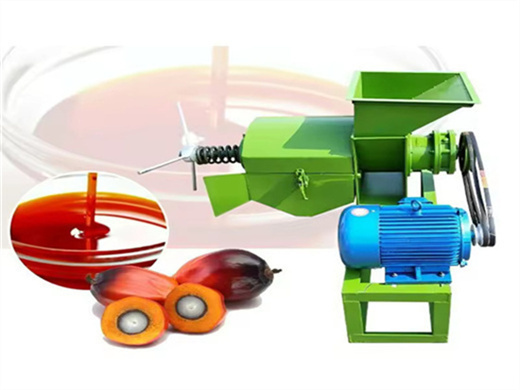

Palm Kernel Oil Processing Machines Palm Oil Extraction

- Type: palm oil processing machine

- Usage/Application: palm fruit, palm kernel

- Production capacity: 1-50TPD

- Voltage: 380v or according to local voltage

- Weight: 1050 KG of cooking seed processing machines

- Dimension (L*W*H): 430*230*350 of the cooking seed processing machines

- Power (W): According to the capacity of the cooking seed processing machines

- Country: lusaka

We have a professional overseas engineering team that can independently complete palm oil equipment installation and commissioning, or collaborate with local construction parties to efficiently implement it – whether it is a 15tph palm oil processing plant in the Democratic Republic of the kenya or the 10tph palm fruit oil pressing line in Thailand, we have achieved complete delivery.

New Palm Kernel Oil Extraction Project Cost in lusaka

- Type: palm oil processing machine

- Production capacity: 150-200 kg/h

- Voltage: 220 V/380 V

- Main components: Motor, Motor

- Weight: 770 KG

- Dimension (L*W*H): 1800*1050 * 1350mm3

New Palm Kernel Oil Extraction Project Cost in lusaka. Utilisation: Huile de palme; Capacité de production: 10T/24h; Tension: 380 V; Dimension (L*W*H): 2010*690*1430mm; Poids: 80600kg; Composants de base: Moteur, Récipient sous pression, pompe, engrenage, roulement, boîte de vitesses; Matière première: paume (paume)/saison/paume/

About $60,000 is needed as equipment investment to run a complete palm oil milling plant with capacity of 50 ton/day. If you want to build a complete oil mill plant including both palm fruit and palm kernel oil extraction, with. palm oil press machine. 1, 5, 10, 15 t/h. 7.5-30 kw. 20-12.5 r/min. 180-6500 kg. 3-10 m³.

Palm Kernel Oil Extracting Machine in lusaka

- Usage: palm oil

- Customized: Customized

- Certification: So9001:2008, CE, SGS and others

- Capacity: 30-1000 tpd

- After-sales service: Rovided: Field installation, commissioning and Tra

- Automatic qualification : Automatic

Setting up a palm oil mill plant isn't easy because a lot of factors such as accessibility and equipment have to be considered. An interesting thing about the global palm oil market is that it needs mini and small palm oil mill plants in order for its marketing operations to be successful.

The palm kernel processing machines developed demonstrate strong oil processing capability and stable continuous operation. It is able to extrude oil from a wide range of edible oil seeds, including peanut, sunflower seeds, coconut, castor beans, mustard, cottonseed, pumpkin seed, grape seed and more, which makes it perfect for all mini oil processing plant and large oil mill. It utilizes advanced mechanical screw pressing method to maximize the oil output. So, it features wide application, high yield, less maintenance, continuous operation and energy-saving.

south africaia high efficiency palm oil extractor in lusaka

- Type: cooking oil extraction machine

- Production capacity: 10 TONS/DAY

- Voltage: 30 hp

- Main components: motor, bearing, gearbox

- Weight: 4000 KG

- Dimension (L*W*H): 2261MM* 686MM*1423MM

Palm oil mill process_Manufacture Palm oil extraction. 5. Palm oil mill process of oil clarifying: Machine-pressed crude oil first diluted with water washing, through settlement and filtration, the fiber material removed from the oil, and then carry out continuous settlement, the whole divided into two parts: oil and sediment.

Explore palm kernel oil extraction methods, from traditional cold pressing to modern solvent extraction. Compare yields, costs, and sustainability to find the best process for your needs. If you want to extract palm kernel oil (PKO), you have several options. Traditional methods like cold pressing and roasting require time and effort but

The Ultimate Guide to the Palm Oil Production Process

- Raw Material: palm

- Production capacity: 1-500T/D

- Power (W ): oil refinery

- Voltage: 380V

- Dimension (L*W*H): oil refinery

- Weight: oil refinery

Time for palm oil extraction machines. PALM OIL EXTRACTION. Now we come to the central step in the palm oil production process: extraction. Separated palm fruits are processed to extract crude palm oil. Fibres and the palm kernel get left behind. There are two commonly used methods for palm oil extraction. Approach 1: wet method.

PALM KERNEL OIL PROCESSING PROCESS. Mechanical extraction processes are suitable for both small, medium and large capacity operations. The basic steps are : Palm Nut Cracking & Shell Separation Unit; Palm kernel Mechanical Pressing Unit; Palm Nut Cracking & Shell Separation Unit. Palm Nut is one of the byproduct of Palm Oil Extraction Plants.