Palm Kernel Oil Extraction: Traditional and Modern Methods

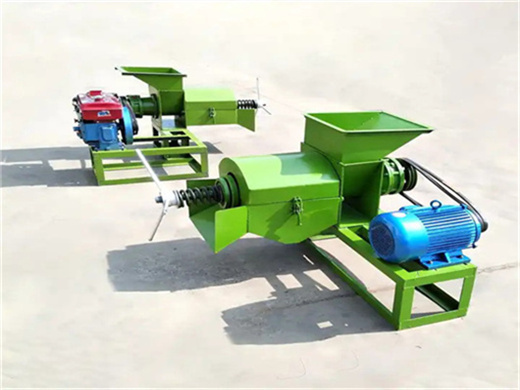

- Type: palm oil extraction equipment

- Usage/Application: palm fruit, palm kernel

- Production capacity: 10 to 500 tpd cooking oil processing

- Voltage: 220V/ 380V/440V

- Weight : 850 KG

- Dimension (L*W*H): 5432*2636*2345

- Power (W): depends on capacity

- Country: ghana

Locally, palm oil is made by boiling palm fruits, pounding or pressing them to extract oil, and skimming the oil from the surface before refining. How is palm kernel oil made step by step? Kernel Collection – Dry kernels after palm oil extraction. Cracking – Break shells to extract seeds. Roasting/Frying – Heat seeds to release oil.

3. PALM OIL PROCESSING

- Type: palm oil processing machine

- Production capacity: 100TPD

- Voltage: 220V/380V

- Main components: Other

- Weight: 450 KG

- Dimension (L*W*H): 1700*1100*1600mm

The extraction of palm oil from boiled palm fruit can be accomplished by handling successive batches of materials or continuously feeding material to the machines. 3.2.1 Batch systems. The batch systems work directly on successive loads of boiled fruit to extract oil in one operation for clarification.

On the other hand, African countries use a similar process of aqueous oil extraction techniques but without the enzyme which then boils the palm mixture to remove the water hence producing a

Palm oil extraction process and nutrients

- Usage: palm oil

- Production capacity: 1TPD-1000TPD

- Voltage: 220 V/380 V

- Weight: 1000kg

- Dimension (L*W*H): 1.5*2.6*3.6M

- Power (W): 7.5 kW

Extraction process. Crude palm oil (CPO) and palm meal (PE) can be obtained from the pulp of palm by the process of boiling, crushing and extracting. At the same time, during the crushing process, the fruit of the palm (i.e., the kernel) is separated, then crushed and the shell is removed, and the remaining kernel is extracted to obtain the crude palm kernel oil (CPKO) and palm kernel meal (PKE).

4.1 Mechanical extraction. Pounding (digestion) and oil extraction are the most tedious and essential operations in traditional palm fruit processing; therefore early efforts concentrated on these tasks. In small-scale processing, digestion, the breaking up of the oil-bearing cells of the palm fruit’s mesocarp, is the most labour intensive.

Local and Modern Methods of Crude Palm Oil Extraction

- Type: cooking oil extraction machine

- Production capacity: 160-200 kgs/hr

- Voltage: 380 V

- Main components: Bearing, Motor, Others

- Weight: 480 KG

- Dimension (L*W* H): 1900*500*760mm

Solvent Extraction of Crude Palm Oil. Solvent extraction is a technique used to separate a particular compound from a mixture based on the solubility of the compound in a specific solvent. In the case of palm oil extraction, a solvent such as hexane is often used to dissolve the oil from the fresh fruit bunches.

extraction. Traditional methods Oil is extracted from fresh coconut, olives, palm fruit shea nut etc. by separating the flesh and boiling it in water. Salt is added to break the emulsion and the oil is skimmed from the surface. In palm oil processing the fruit is first heated in a ‘digester’. Manual methods Oil can be extracted by pressing

(PDF) Palm Oil Processing - Academia.edu

- Raw Material: palm

- Production capacity: 50-800 kg

- Dimension (length x width x height): 46*16*28 cm

- Voltage: 110 V-220 V

- Weight: 11 KG

- Main components warranty: 2 years

A general description of palm oil processing and the associated unit operations necessary to obtain the oil will follow. The individual fruit, (Fig. 2) ranging from 6 to 20 gm, are made up of an outer skin (the exocarp), a pulp (mesocarp) containing the palm oil in a fibrous matrix; a central nut consisting of a shell (endocarp); and the kernel, which itself contains an oil, quite different to

the most produced bi-product of palm oil industry. As palm oil fresh fruit bunches (FFB) are approximately consist of 20% of EFB, and it was estimated one tonne of EFB was produced with one tonne of palm oil (Chang 2014). Based on this estimation, there are 19.92 million tonnes of produced EFB in year 2017, as the crude palm oil (CPO