Sunflower Oil Prices: Factory Insights, Trends and Chart Updates

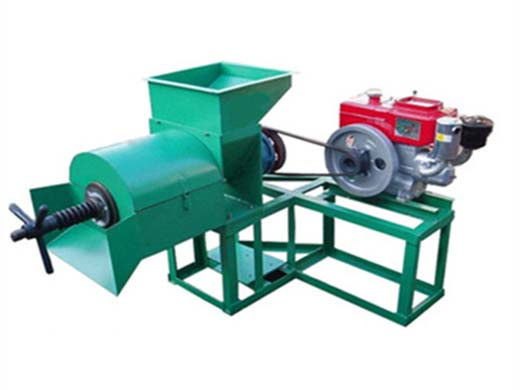

- Type: sunflower oil mill

- Usage/Application: sunflower

- Production capacity: 3-4 kg, 400 kg/h

- Voltage: 180-220v/50hz, 220v

- Main components: Motor

- Weight: 9.8KG, 9,800kg

- Dimension (L*W*H) : 48*27.5*24CM

- Country: botswana

Crude Sunflower Oil Prices vs. Refined Oil Prices. Understanding the difference between crude and refined sunflower oil pricing. Why crude oil prices matter for market trends. Sunflower Oil Price Trends Since 2012. Historical overview of sunflower oil prices from 2012 to the present. Key factors influencing price changes over the years.

Start Sunflower Oil Production Line – Factory Price Oil

- Type: sunflower oil processing machine

- Production capacity: 100% oil press machine

- Voltage: 220V/380V/440V

- Weight: 950KG

- Dimension (L*W* H): 1950*1300*1900, according to capacity

- Power (W): 5.5 ~ 18.5 KW

Start Sunflower Oil Production Business. Sunflower seed belongs to oil seed with shell, with oil content of 22-40%. As a common and increasingly popular edible oil , sunflower oil ranks fourth among all vegetable oils in worldwide oil consumption, after palm oil, soybean oil and rapeseed oil.

10TPD Sunflower Seed Oil Press Line and 3TPD Refinery Plant in Moldova; 150TPD Sunflower Oil Processing Plant Business in Russia; Set up Small Coconut Oil Refining Factory; Market Report to Invest a Small Palm Oil Refinery Business; Business Plan for Establishing Rice Bran Oil Manufacturing Plant

Sunflower Oil Manufacturing Plant Report 2025 | Setup Cost

- Usage: sunflower oil

- Production capacity: 98

- Voltage: 220V/380V

- Warranty: 1 year, 1 year

- Weight: 260 KG

- Dimension (L*W*H): Customization

IMARC Group’s report titled “Sunflower Oil Manufacturing Plant Project Report 2025: Industry Trends, Plant Setup, Machinery, Raw Materials, Investment Opportunities, Cost and Revenue” provides a complete roadmap for setting up a sunflower oil manufacturing plant. It covers a comprehensive market overview to micro-level information such as

Sunflower oil mill plant price is depending on the capacity you required. Complete set sunflower oil processing machine. 1. Sunflower oil pretreatment and pre-press machine introduction: Sunflower oil pretreatment process generally refers to the process of extracting oil from oil seeds.

Complete Sunflower Oil Production Line. Sunflower Oil Mill

- Type: cooking oil extraction machine

- Production capacity: 50-3000TPD

- Power (W): As sunflower seed oil press production every day

- Voltage: 380v 440v

- Dimension (L*W*H): As sunflower seed oil press production per day

- Weight: Depends of sunflower seed oil press production

Capacity 1 TPD to 5,000 TPD. The sunflower oil production line includes cleaning, shelling, kernel separation, cooking, pressing, filtering, extracting, refining, and packing. Some steps can be customized based on specific requirements, fully automated or semi-automatic options for varying budget levels.

The cost of 1ton/day oil refinery plant is about $19800. For 1ton/day sunflower oil dewaxing machine, the price is about $13000. For large scale produciton line, the cost range of different project design could be tens of thousands of dollar. So if you want to know more about the cost of commercial scale oil mill, please feel free to contact us!

How much does it cost to set up a sunflower oil mill plant?

- Raw Material: sunflower

- Voltage: 380V-415V

- Dimension (L*W*H): depends on oil machine mode the oil machine

- Power (W): depends on oil machine mode

- Weight:depends on the mode of the oil machine

- Certification:CE,BV,ISO9001

4.Raw material prices. The larger the scale of sunflower oil mill plant, the larger the daily processing capacity of the plant, the more raw materials it needs, and the higher the plant investment cost. Henan Glory suggests that you can collect sunflower oil seeds from farmers or suppliers at a large quantity &lower price, and establish a long

Mimi Oil Mill Plant Setup Small(10TPD) Sunflower Oil Production Line in Uganda. Mini Oil Mill Plant: a cleaning sieve, cooking machine, integrated oil press, and screw elevator. Compared to large-scale automated oil mills, it requires less space and investment, while still encompassing full functionality of an oil mill.