Cottonseed oil refining method, how to refine cottonseed oil

- Type: cottonseed oil refining equipment

- Usage/Application: cottonseed

- Voltage: 380V

- Appearance: Vertical

- Custom: Customized

- Press Series: Second

- Materials Press: Sunflower, Soybean, Coconut, Peanut, Mustard

- Country: south africa

The absorption rate of cottonseed oil by the human body is 98%. 3. Cottonseed oil refining process. Cottonseed oil crude oil→degumming→deacidification→washing→decolorization→deodorization→winterization→finished first-grade cottonseed oil. 4. Main equipment for cottonseed oil refining. Neutralization pot: used for acid refining

Title: -PROJECT PROPOSAL ON EDIBLE OIL PROCESING COMPANY

- Type: cottonseed oil refinery machine

- Production capacity: 100kg/h-1000kg/h

- Voltage: 380V, 380V

- Main components: Motor, olive oil processing machine

- Weight: 1480 KG

- Dimension (L*W*H): 2600 *2100*2200 mm

south africa Seed: - Recovering rate of south africa seed crude oil to refined oil under the technology to be used (press solvent extraction method) results in 97% will be refined oil. The res 3% is refiner loss. Cotton Seed: - By the same token, the conversion rate of crude oil to refined oil per a given quantity of cotton crude oil is about 99%.

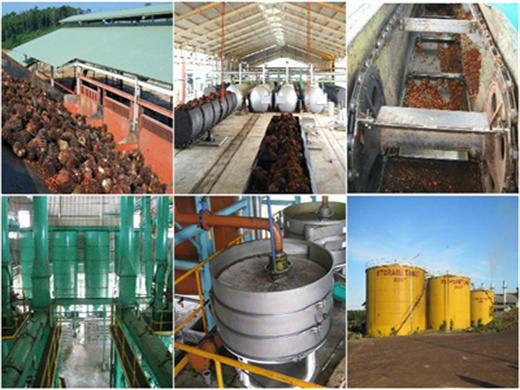

Fractionation and Refining Crude Cottonseed Oil. 30ton/day Cottonseed Oil Refinery Plant. Refining crude cottonseed oil to produce edible / cooking oil. It involves bleaching, De-acidification, deodorization, and degumming. Fractionation can get solid and liquid oil through solid and liquid separation and cooling crystallization.

Equipment and Cost to Start Oil Refining Business in south africaia

- Usage: cottonseed oil

- Production capacity:140-280 kg/h

- Voltage:380 V/415/440 V

- Main components warranty: 2 years

- Weight: 1000 KG

- Dimension (length x width x height):1800* 1300*1680

Edible oil refining process must not damage the neutral oil and natural antioxidants, so that the edible oil produced is of high quality. (Read more: Cotton Seed Cake Manufacturing Process >>) Oil Refining Plant for Sales. The process of refining crude oil into edible oil is very complex. Refining can be referred to as the "deacidification

Cottonseed oil contains pressing cottonseed oil, solvent extraction cottonseed oil, genetically modified organism cottonseed oil, crude cottonseed oil, and the finished product of cottonseed oil. Its color is deep redder than other oils, can be used as cooking oil after refining, as well as contains a large sum of fatty acids that are essential

Edible Oil Refining Process Systems

- Type: cooking oil refining machine

- Production capacity: 10T-5000TPD

- Power (W): 10kw-50kw

- Voltage: 220V/380V/440V

- Dimension (L*W*H): 2500mm*2000mm*3000mm

- Weight: 2T-20T

In physical refining, the free fatty acids in the oil are removed using multi-stage stripping during the deodorization process. Physical refining normally has the following general characteristics: • can only be used with certain, limited types of crude oils – for example palm oil, but not cottonseed oil or fish oil • depends on efficient

Human body consumption of cottonseed oil is up to 98%. Cottonseed Oil Needs Refining. It is said that refining process can reduce toxicity. Cottonseed oil is one of main cooking oil. But crude cottonseed oil contains gossypol (approximate 1%), colloid and waxiness (content vary with shell content), and the quality is poor.

cotton seed oil mill project report

- Raw Material: cottonseed oil

- Production capacity: 5TPD-100TPD

- Dimension (length x width x height): 500*200*700mm

- Voltage: 220V/380V

- Weight: 190 KG

- Main components: Motor, Bearing

The extracted oil meal contains 0.10% to 0.20% free gossypol, which is only half of the pre-pressed cottonseed material. Oil Refining; The crude cottonseed oil contains about 2% or more gossypol, phospholipids, fatty acids and other non glyceride composition that affect the flavor and sensory index; therefore, it must go through degumming

Cottonseeds can be once-pressed and then sent to the cottonseed oil refinery plant directly. For the capacity of more than 20 tons per day, usually, solvent extraction method is adopted with cottonseed oil pre-press used to extract part of the oil. The machine has a large capacity and the cake has low residual oil rate and is easy for solvent penetration. The pre-pressing and extraction method produces cottonseed oil and crude cottonseed oil refining.